Kyrgyzstan cobblestone crushing production line

Crushing equipment is a core production tool in the construction industry, and its safe and efficient operation directly affects project progress and personnel safety. Correct installation is a prerequisite for safe operation, while a deep understanding of the equipment's working principles will help operators better anticipate and respond to various situations during operation. This article aims to provide a practical and comprehensive safe operation guide for crushing equipment operators, quarry managers, and construction industry practitioners.

I. Crushing Equipment Installation Guide (Basic Pre-Operation Skills)

1. Site Preparation Stage

Before the equipment arrives on site, all debris and obstacles must be thoroughly removed to ensure the work area is clean and tidy. Use professional instruments to measure and level the ground to establish a stable foundation for the equipment, preventing displacement or tilting during operation due to an unstable foundation.

2. Foundation Construction Stage

According to the technical specifications provided by the equipment manufacturer, accurately excavate the foundation pit and trench. Lay a crushed stone base layer with a thickness of no less than 300mm, using a layered compaction process to ensure the foundation's bearing capacity meets the equipment requirements.

3. Equipment Installation Phase

Place core components such as the main unit and conveyor belt strictly according to the layout diagram, ensuring that the spacing between components meets safety standards. A professional electrician is responsible for installing the distribution box and connecting conduits. All wires must be protected with flame-retardant conduits, and the grounding resistance value must be less than 4Ω. Finally, secure all components with high-strength bolts and perform anti-loosening measures.

4. Commissioning and Acceptance Phase

Under the guidance of a professional engineer, conduct the initial power-on test, checking each electrical system operating parameter. After fully tightening all connections, conduct no-load and load test runs, recording key data such as equipment vibration and noise.

Professional Tip: Although installation is mainly completed by a professional team, operators who understand the installation key points can help to promptly detect equipment abnormalities later.

Kyrgyzstan cobblestone crushing production line

II. Three Core Safety Operating Procedures

1. Pre-Start Preparation

Daily Checklist:

• Check if the lubricating oil level is within the marked range

• Confirm that there is no residual material inside the crushing chamber

• Check if the conveyor belt tension is appropriate

• Test if the emergency stop button is sensitive and effective

• Confirm that all protective covers are intact and in place

2. Precautions During Operation

• Operators must wear safety helmets, dust masks, and safety glasses at all times.

• Feed evenly to avoid overloading the equipment.

• Continuously monitor motor temperature and equipment vibration.

• Cleaning or maintenance work is strictly prohibited while the equipment is running.

• Maintain a safe distance from the equipment, paying special attention to the risk of splashing materials.

3. Shutdown Precautions (Detailed Explanation)

Abnormal Handling Procedure: If an abnormality is detected → immediately press the emergency stop button → hang a "Do Not Operate" warning sign → investigate the cause → restart only after thoroughly troubleshooting

Standard Shutdown Sequence:

1. Stop the feeding system first

2. Wait until all the stone in the crushing chamber is discharged

3. Stop the crushing main unit, screening equipment, and conveying system sequentially.

Post-shutdown operating procedures:

• Disconnect the main power supply and lock it.

• Clean the hopper using a special tool (⚠️ Do not clean directly by hand).

• Cover all protective covers to prevent rainwater and foreign objects from entering.

• Fill out the equipment operation record form.

Seasonal maintenance points: After shutdown in winter, the circulating cooling water must be drained and antifreeze added to prevent bearings and pipes from freezing and cracking.

III. In-depth analysis of working principle

1. Collaborative operation of core systems

Modern stone crushing equipment adopts a modular design with four major systems working in precise coordination:

Feeding system: The amount of stone fed is evenly controlled by a vibrating feeder to avoid equipment overload or idling.

Crushing system: The core crushing chamber adopts the principle of layered crushing. The moving cone and fixed cone form a multi-stage crushing chamber, and the eccentric sleeve rotation generates a strong squeezing effect. The latest model also employs hydraulically adjustable discharge port technology to achieve precise particle size control.

Screening System: A multi-layer vibrating screen uses screens of different apertures to classify materials. Unqualified materials are returned to the crusher for secondary crushing, forming a closed-loop cycle.

Conveying System: Includes belt conveyors and bucket elevators, featuring anti-deviation design and emergency pull-rope switches to ensure continuous and stable material transport.

Crushing Equipment Safety Operation Guide

2. Detailed Process Flow

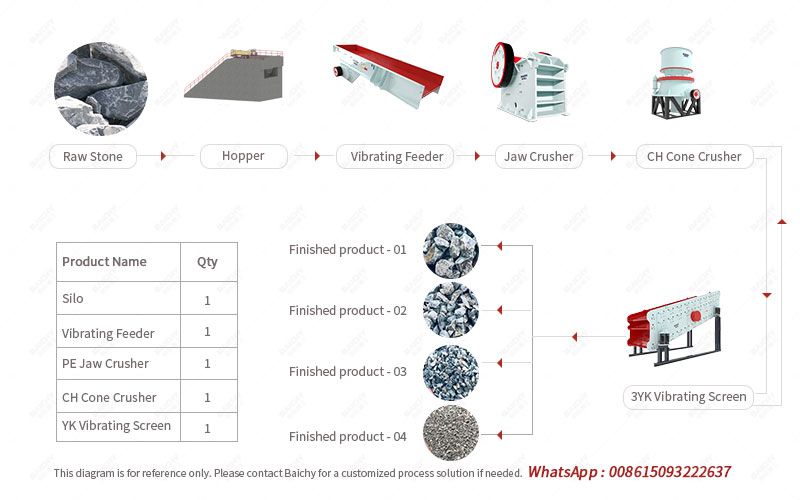

Raw Material → Vibrating Feeder → Jaw Crusher (Coarse Crushing) → Cone Crusher (Medium Crushing) → Vibrating Screen → Qualified Material → Conveyed to Stockpile

↑ ↓ Unqualified Material → Returned to Crusher

3. Industry Value and Technological Innovation

According to a 2021 survey by the Building Materials Research Institute, modern stone crushing plants account for 78% of the building aggregate market supply. The new generation of intelligent stone crushing equipment achieves automated production through a PLC control system, reducing energy consumption by 30% and dust emissions by 65% compared to traditional equipment, truly realizing green production.

V. Successful Case Studies

Peru Mining Project: The APY3-1210F mobile impact crusher operated stably for 6000 hours in a high-altitude environment, achieving an hourly output of 250 tons, perfectly adapting to complex working conditions.

Tanzania River Pebble Sand Making Project: Employing a wet production process, effectively controlling dust pollution, the finished product has excellent particle shape, meeting the requirements of high-end construction aggregates.

Malaysia Urban Construction Waste Treatment Project: Three sets of mobile tracked crushers achieved a 90% resource utilization rate for construction waste, providing a model for sustainable urban development.

VI. Conclusion and Call to Action

As core equipment in infrastructure construction, the safe operation of crushing equipment not only affects production efficiency but also directly impacts the safety of operators. Only through standardized installation, strict adherence to operating procedures, and a thorough understanding of the equipment's working principles can the equipment's efficiency be fully utilized and safe production ensured.

Take Action Now: For specific equipment model safety operation manuals or to arrange on-site training, please contact our technical team for professional support.

Further Reading Suggestions:

• How To Choose A Suitable Mining Stone Crusher?

• Key Points In Designing Sand And Gravel Aggregate Production Line

• 500 t/h Crushing Production Line Case

The technical parameters in this article are for reference only. Please refer to the instruction manual provided by the equipment manufacturer for specific operating procedures.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!