Crawler Mobile Jaw Crusher

In today's mining and construction aggregate production, which demands high efficiency, flexibility, and reduced operating costs, traditional fixed crushing production lines are often insufficient to meet all needs. It is against this backdrop that crawler-mounted jaw crushers, as pioneers of mobile crushing equipment in mining, are rapidly transforming operating models. This article will delve into this revolutionary equipment.

I. Topic Analysis: Why are crawler-mounted jaw crushers becoming mainstream?

A crawler-mounted jaw crusher essentially combines a classic jaw crusher with a highly mobile crawler chassis. It addresses the core pain points of dispersed material distribution and constantly shifting work faces in quarries, mines, and construction waste processing sites. Its design philosophy is "bringing the equipment to the material, rather than transporting the material over long distances to the equipment," thereby significantly reducing truck transportation costs and reliance on fixed infrastructure.

II. Equipment Overview: An Integrated High-Efficiency Crushing Solution

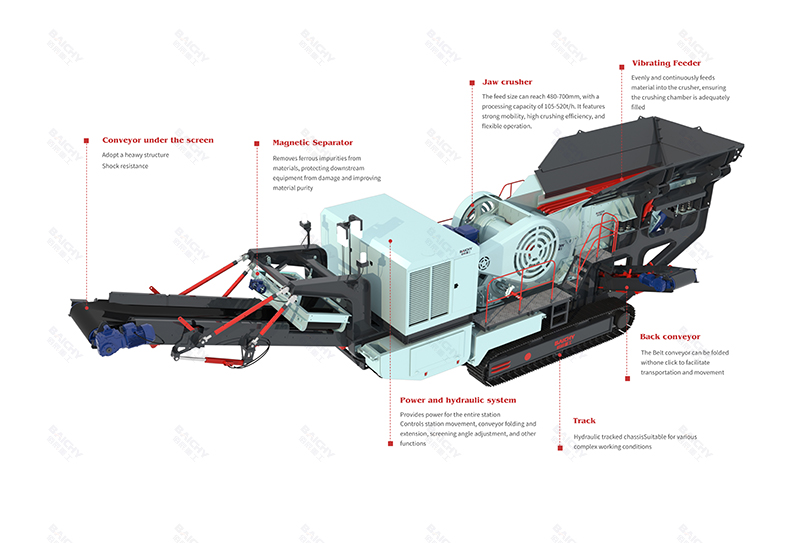

A typical crawler-mounted jaw crusher is a highly integrated, self-contained working unit. It mainly includes:

Powerful Jaw Crusher Main Unit: Featuring a heavy-duty structure and an optimized crushing chamber, it can efficiently process hard materials such as river pebbles, granite, and basalt, making it a reliable choice for primary crushing.

Crawler Mobile Chassis: Equipped with heavy-duty hydraulically driven tracks, it has low ground pressure and can move freely on rugged and soft construction sites, even allowing for remote control, ensuring high safety.

Integrated Feeding and Pre-screening System: Usually equipped with a vibrating feeder and pre-screening mesh, it can pre-screen out soil and fine materials, or bypass already qualified materials directly, improving the efficiency of the main unit and reducing wear.

Intelligent Control System: A centrally controlled electrical control cabinet with a touch screen allows for one-button start-up, discharge opening adjustment, and monitoring of operating parameters, making operation simple.

III. Core Advantages: Five Reasons to Choose a Crawler-Mounted Jaw Crusher

Unparalleled Mobility and Flexibility: No need for fixed foundations; it can be quickly moved within or between construction sites, closely following the mining face, significantly shortening material transportation distances.

Significant Operating Cost Savings: Minimizes or even eliminates the need for truck fleets for on-site material transfer and their associated fuel, labor, and maintenance costs.

Rapid Deployment and Easy Installation: The equipment can begin working almost immediately upon arrival at the site, saving the complex infrastructure construction and installation time required for fixed production lines.

Adaptable to Complex Working Conditions: The crawler chassis requires minimal site leveling and can adapt to complex terrains such as mountainous and wetland areas, expanding the operating range.

Environmental Protection and Noise Reduction: Because the equipment can operate close to the material source, it reduces the back-and-forth movement of heavy trucks, thereby reducing overall noise, dust, and carbon emissions.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

IV. Application Cases: Our Equipment in Action

One of our crawler-mounted jaw crushers was successfully applied in a granite quarry in North China. The customer faced the challenge of scattered mining areas and long transportation distances. After deployment, the equipment moved three times within one quarter as the mining face advanced, reducing the transportation cost per ton of material by approximately 40%, and increasing overall project production efficiency by 25%. The customer was very satisfied with the return on investment.

V. Related Equipment Recommendations: Creating a Complete Mobile Crushing and Screening Process

To create a more efficient production closed loop, we recommend considering combining the crawler-mounted jaw crusher with the following equipment:

Crawler-mounted cone crusher/impact crusher: Used as a secondary crusher to produce finer-sized high-quality aggregates.

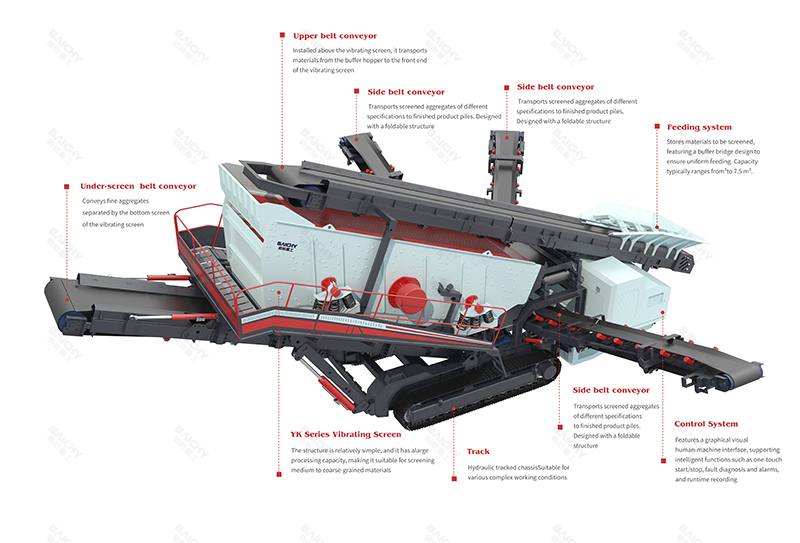

Crawler-mounted screening plant: Used for precise classification of crushed materials to obtain multiple final products that meet specifications.

Crawler-mounted feeder: Ensures continuous and uniform feeding to the main crusher, protecting the equipment and optimizing the process.

VI. Frequently Asked Questions (FAQ)

FAQ 1: What are the maximum feed size and processing capacity of the crawler-mounted jaw crusher?

This depends on the specific model. Our equipment range is wide, with maximum feed sizes ranging from 650mm to over 1200mm, and processing capacities from 150 tons per hour to over 600 tons per hour. We need to recommend the most suitable model based on your material hardness and expected output.

FAQ 2: How is the equipment powered in the field?

The equipment comes standard with a diesel engine, enabling completely self-sufficient power supply. Some models also offer an electric drive option, which can be used when a stable power grid is available on-site to further reduce operating costs.

FAQ 3: Is the equipment difficult to maintain?

We have designed a structure that is easy to maintain. Key lubrication points are centrally located, and wear parts (such as jaw plates) are easy to replace. We also provide a remote intelligent monitoring system that can provide early warnings of potential malfunctions, and a comprehensive after-sales support team to ensure your equipment continues to operate efficiently.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!