Crawler Mobile Jaw Crusher

In the rapidly evolving mining and aggregate production industry, efficiency and flexibility are key to success. Traditional fixed crushing lines require complex infrastructure, are difficult to relocate, and have poor adaptability to complex terrain. It is against this backdrop that mobile jaw crushers, particularly those mounted on crawler chassis, have become game-changers in the industry. As a professional manufacturer of mobile crushing equipment for mining, we will delve into all aspects of this powerful machine.

Equipment Overview: What is a Crawler Mobile Jaw Crusher?

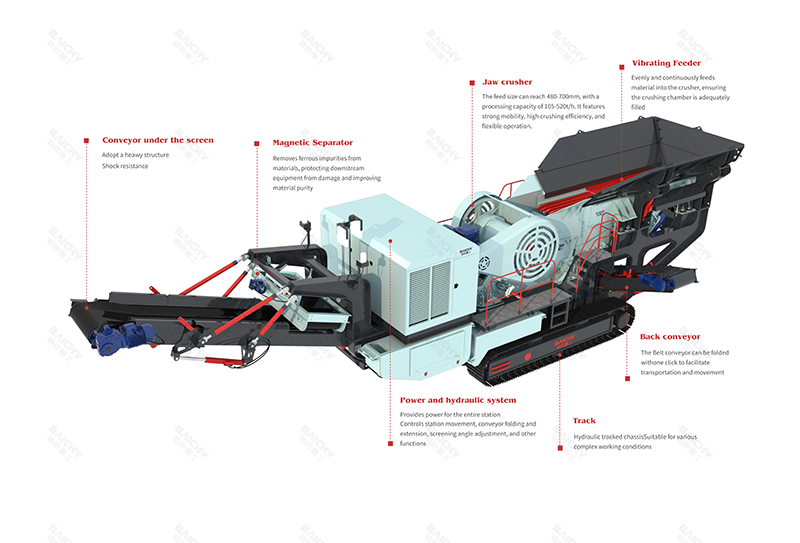

A crawler mobile jaw crusher, as the name suggests, integrates a mature jaw crusher, feeder, pre-screening equipment, and discharge conveyor onto a robust crawler chassis. This forms a highly integrated "single-unit crushing station." Its core component – the jaw crusher – is renowned for its robust structure and high crushing ratio, making it the preferred primary crushing equipment for processing hard, abrasive rocks (such as granite, basalt, and quartz). The crawler drive design provides unparalleled mobility, allowing it to move freely in rugged mining sites, quarries, and even construction waste processing sites.

Core Advantages: Why Choose a Crawler Mobile Jaw Crusher?

Compared to traditional solutions, crawler mobile jaw crushers demonstrate overwhelming advantages in several aspects:

Unparalleled Mobility and Rapid Relocation: The equipment is self-propelled with a crawler drive, eliminating the need for a tractor truck, allowing for flexible movement within the work area, and even enabling "crushing while moving." During relocation, hydraulic support legs and folding mechanisms allow for quick setup, significantly reducing equipment installation and dismantling time from weeks to hours.

Significantly Reduced Operating Costs: It eliminates the need for cement foundations, steel structures, and extensive labor costs required for fixed production lines. Optimized fuel efficiency and on-site crushing of materials avoid the expensive transportation costs of hauling large quantities of raw ore to a fixed crushing plant.

Direct Access to Crushing Points, Improving Resource Utilization: The equipment can be driven directly to the working face of the ore body or near the blasting pile, meaning that previously uneconomical ore resources due to long transportation distances can now be processed, increasing overall resource recovery rates. Adaptability to Harsh Terrain and Environments: The low ground pressure of the crawler tracks allows for easy handling of soft, muddy, or uneven mining roads, expanding the operating range.

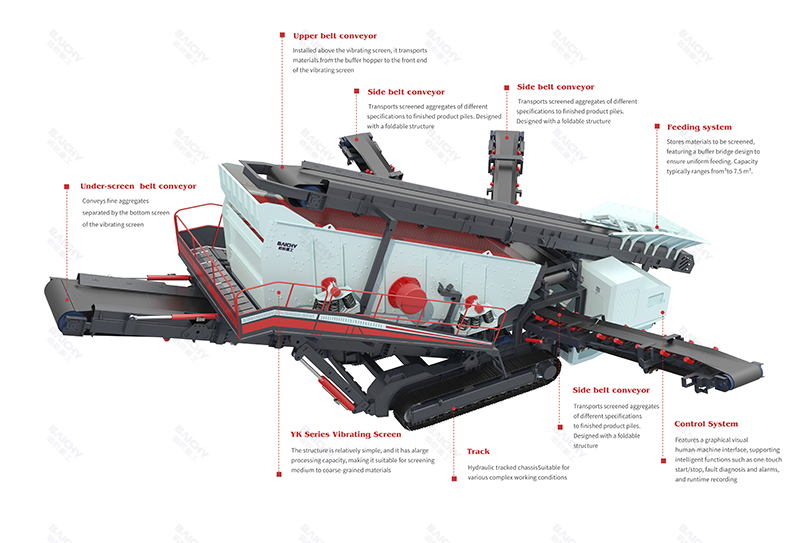

Intelligent Control and Convenient Maintenance: Modern models are usually equipped with PLC intelligent control systems and wireless remote control, enabling one-button start/stop and fault diagnosis. The centralized lubrication system and modular design make daily maintenance and replacement of wear parts more convenient and efficient.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Application Cases: From Granite Quarries to Urban Construction Waste Recycling

Case 1: A large granite quarry: This quarry has dispersed ore bodies. After introducing a high-capacity crawler-mounted mobile jaw crusher, the crushing station position can be adjusted at any time according to the mining progress. A single machine can complete primary crushing and directly feed the semi-fixed secondary crushing station, increasing overall production efficiency by approximately 30% and reducing transportation costs by 25%.

Case 2: Urban construction waste resource utilization project: At the demolition site, the equipment is driven directly in to perform preliminary crushing of large pieces of waste concrete and bricks, separating the rebar. The resulting aggregate can be directly used for site backfilling or as raw material for recycled building materials, achieving the environmental goal of "on-site processing and turning waste into treasure."

Related Equipment Recommendations: Building an Efficient Mobile Production Line

A crawler-mounted mobile jaw crusher is often the core of a mobile crushing production line. To form a closed loop, we usually recommend pairing it with:

Crawler-mounted mobile cone crusher or impact crusher: As a secondary crushing device, it forms a continuous crushing process with the mobile jaw crusher.

Crawler-mounted mobile screening station: For precise classification of crushed materials to obtain finished aggregates of various specifications.

Mobile feeders and plate feeders: To ensure uniform and continuous feeding to the mobile jaw crusher, protecting the equipment and optimizing capacity.

Frequently Asked Questions (FAQ)

Q1: What are the maximum feed size and capacity of a crawler-mounted mobile jaw crusher?

A1: This depends on the specific model. Current mainstream models have a wide range of feed opening sizes, capable of handling huge rocks with side lengths exceeding 1 meter, with theoretical hourly production ranging from 150 tons to over 800 tons. Our engineers can recommend the most suitable model based on your material hardness and target output.

Q2: Is its fuel consumption and daily maintenance complex?

A2: Modern mobile jaw crushers use high-efficiency, energy-saving diesel engines and feature functions such as automatic idling to reduce unnecessary fuel consumption. Daily maintenance points (such as lubrication points and inspection windows) are designed for ease of access. Operators can complete daily inspection and maintenance tasks with only basic training.

Q3: Can it crush very hard rocks? How durable is the equipment?

A3: Absolutely. The core crushing components of the mobile jaw crusher (moving jaw plate, fixed jaw plate, eccentric shaft) are cast from high-strength alloy steel and undergo special heat treatment processes, specifically designed to withstand highly abrasive rocks. The overall frame structure is robust and can withstand the challenges of high-intensity continuous operation, ensuring a long service life and low failure rate.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!