Crawler Mobile Jaw Crusher

Overview: What is a Track-Mounted Jaw Crusher?

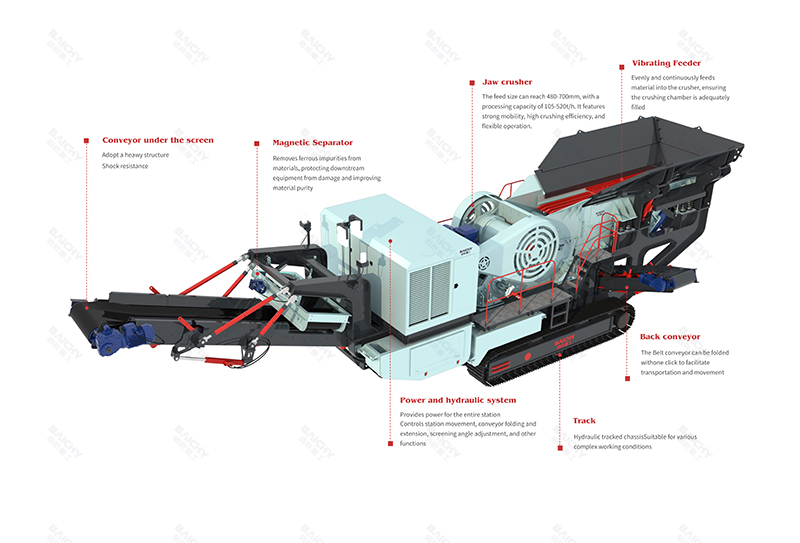

A track-mounted jaw crusher is an integrated heavy-duty mobile crushing equipment that combines a jaw crusher, vibrating feeder, pre-screening system (in some models), and a track-mounted chassis. It is widely considered the "heart" or "first stage" of any mobile crushing production line, designed specifically for processing various hard, large-sized primary rocks (such as granite, basalt, and river pebbles). As a track-mounted mobile crusher, it possesses excellent all-terrain mobility, allowing the primary crushing stage to be moved directly to the blasting face or mining point, thereby completely revolutionizing the material handling model of traditional mines and large quarries, achieving a cost revolution from the source.

Analysis of the Core Advantages of Track-Mounted Jaw Crushers

As the absolute mainstay of primary crushing, the core advantage of the track-mounted jaw crusher lies in its robust, efficient, and flexible "front-line operation" capabilities.

Powerful Primary Crushing Capacity and High Reliability

Handling the Hardest Raw Materials: Using a heavy-duty jaw crusher as its core, the movable and fixed jaw plates are made of high-strength manganese steel, and the crushing chamber is optimized to easily grip and crush large, high-hardness raw materials, providing a stable feed for subsequent secondary crushing processes.

Robust Design for Continuous Operation: The entire machine structure is designed for heavy-duty working conditions, with ample safety margins for key bearings and structural components. Its simple and reliable working principle allows it to maintain a high operating rate and long service life in harsh mining environments, making it the cornerstone of projects that demand high availability.

Excellent Mobility and Investment Efficiency

Eliminating Truck Transportation, Significantly Reducing Costs: The most revolutionary value of the track-mounted jaw crusher is its ability to move the crusher to the material pile. This directly eliminates the expensive and inefficient truck transportation between the mining face and the fixed primary crusher, saving up to 30%-50% in transportation costs and reducing fuel consumption, carbon emissions, and equipment maintenance.

Rapid Relocation and Flexible Deployment: Thanks to the track-mounted chassis, the equipment can move quickly and independently between different mining areas or different project sites. This allows one piece of equipment to serve multiple mining sites, significantly improving asset utilization and return on investment, especially suitable for phased mining or contract crushing projects.

Intelligent and Pre-screening Functions

Integrated Pre-screening for Improved Efficiency: Many advanced models integrate an independent pre-screener (such as a vibrating grizzly or single-deck screen) at the feeding end, separating natural fines and soil before the material enters the crusher. This not only increases effective capacity and reduces liner wear but also directly produces some qualified finished products, optimizing the overall production process.

Intelligent Control for Safe Operation: The standard wireless remote control allows operators to move, steer, and perform basic operations away from the equipment. The advanced PLC control system monitors key parameters (such as material level, pressure, and temperature), enabling automated feeding and overload protection, ensuring safety and efficiency.

| Key Words | Crawler-Type Mobile Crusher |

|---|---|

| Product Model | Crawler Jaw Crusher |

| Capacity | 80-520t/h |

| Core Functions | Tracked walking systems enable mobile operations |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Successful Application Cases

Case Study 1: Large Granite Mine Transportation Cost Optimization Project

A large granite mine's existing fixed primary crushing station was located in a remote area. As the mining face advanced, transportation distances increased, and the truck fleet and fuel costs became a heavy burden. We provided a high-capacity crawler-mounted jaw crushing plant. This equipment can move with the mining face monthly, directly crushing large rocks over 1 meter in size to less than 250mm at the edge of the mining area, and then transporting them to the next stage via efficient and energy-saving belt conveyors. This completely eliminated the truck transportation link, reducing annual operating costs by more than 40%, and significantly shortening the investment payback period.

Case Study 2: Aggregate Contractor with Multiple Job Sites

An aggregate production contractor served multiple road construction projects simultaneously, each with different raw materials and timelines. They purchased a medium-sized crawler-mounted jaw crushing plant. Thanks to its rapid relocation capability (job site changes can be completed within half a day), the equipment served three different project sites in one year, acting as a primary crushing unit in conjunction with mobile cone crushers or impact crushers, flexibly producing various specifications of aggregates, achieving "one machine for multiple uses" and maximizing equipment value.

Equipment Selection and Recommendations

Choosing the right crawler-mounted jaw crusher is a critical decision:

Selection based on feed size and capacity: The primary considerations are the maximum raw material size to be processed and the desired hourly output. This will determine the feed opening size and model of the jaw crusher.

Is pre-screening necessary? If the raw material has a high soil content or contains a large amount of natural fines, it is strongly recommended to choose a model with an integrated pre-screening feeder. This is a cost-effective option for improving the processing efficiency of pure raw materials and the quality of the final product.

Focus on maintainability design: Check whether the lubrication points are centralized, whether the jaw plates are easy to replace (hydraulic adjustment and fastening devices), and whether the equipment is equipped with a complete maintenance platform and safety passages. These designs will directly affect the convenience and safety of daily maintenance.

Frequently Asked Questions (FAQ)

1. Can a crawler-mounted jaw crusher be used as a complete production line on its own?

Although crawler-mounted jaw crushing stations primarily perform primary crushing tasks, producing semi-finished products with larger particle sizes, they can be used as a standalone unit when the project only requires the production of railway ballast, large fill stones, or large stones of specific specifications. By adjusting the discharge opening, the product can be used directly. For most situations requiring multi-specification finished aggregates, it needs to be combined with secondary crushing equipment (such as a crawler-mounted cone crusher or impact crusher) and a screening station to form a combined production line.

2. What are the fuel consumption and maintenance costs of the equipment?

Due to the elimination of dozens of trucks for transportation, the greatest benefit of a crawler-mounted jaw crushing station is the systemic reduction in overall costs. Its own fuel consumption (diesel-driven) and maintenance costs are clear and controllable, far lower than the combined costs of the large fleet of trucks it replaces. Efficient engines and intelligent power management systems also help optimize fuel efficiency.

3. How to handle very sticky and wet raw materials?

For sticky soil or high-humidity materials, we recommend: 1) Choosing a model with a powerful pre-screening function to separate sticky fines in advance; 2) Installing a removable bar screen or grate on the feeder to prevent clogging; 3) In some extreme cases, it may be necessary to consider pre-drying the raw materials or using specialized feeding equipment. Our engineers can provide tailored recommendations based on your specific material samples.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!