Gyratory Crusher

In mining and large-scale infrastructure projects, large rotary crushers (typically referring to gyratory crushers or large cone crushers) are critical equipment in the primary crushing stage. As a professional manufacturer of mobile mining crushing equipment, we understand the importance of these devices for efficiently processing large quantities of rock. This article will provide an in-depth analysis of the unique value and application advantages of large rotary crushers from a professional perspective.

Gyratory Crusher PDF, Download ↓↓↓

I. Subject Analysis: The Strategic Significance of Large Rotary Crushers

Large rotary crushers play the role of the "first line of defense" in the stone processing industry. These devices can directly process raw ore transported from the blasting site, crushing huge rock blocks into sizes suitable for subsequent processing. Compared to smaller crushing equipment, the advantages of large rotary crushers lie in their continuous crushing capacity, high throughput, and lower unit crushing costs, making them particularly suitable for large-scale mining operations.

With the continuous expansion of mining scale, the demand for crushing equipment has shifted from traditional fixed-type solutions to more flexible mobile solutions. Mobile large rotary crushers can be deployed directly to the mining site, reducing material transportation distances and significantly improving overall operational efficiency, which is an important development trend in modern mining.

II. Overview: Working Principles and Types of Large Rotary Crushers

Large rotary crushers are mainly divided into two types: gyratory crushers and large cone crushers. Both achieve rock crushing through rotational motion, but their structure and working methods differ.

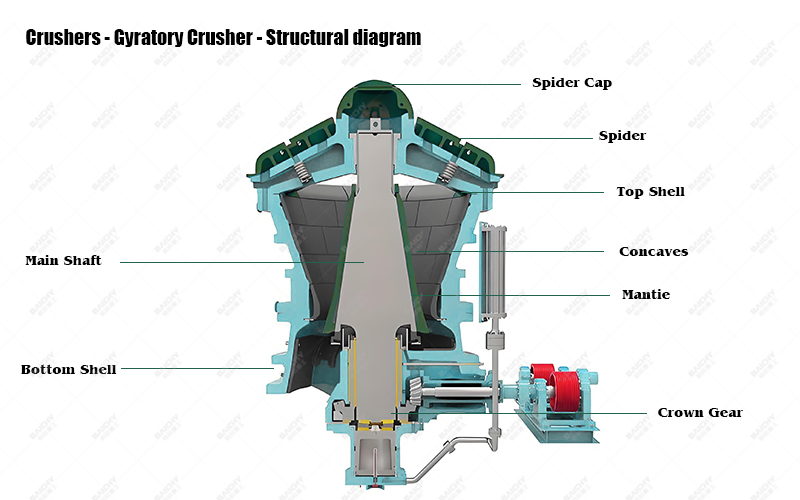

Working Principle of Gyratory Crushers

Gyratory crushers use the rotation of the main shaft and eccentric sleeve to cause the crushing cone to perform a gyratory motion. The gap between the moving cone and the fixed cone changes periodically, applying compression, splitting, and bending forces to the material, achieving continuous crushing of the rock. This equipment is particularly suitable for processing large quantities of medium-hard and harder rocks.

Working Characteristics of Large Cone Crushers

Large cone crushers use an eccentric device to cause the crushing cone to rotate and oscillate. Their crushing chamber design is more optimized, providing a higher crushing ratio and better product particle shape. Modern large rotary crushers are usually equipped with hydraulic adjustment and overload protection systems, making operation safer and more convenient.

| Key Words |

Limestone Crushing & Screening Plant |

| Product Model |

Gyratory Crusher |

| Feed Size |

≤1300mm |

| Motor Power |

400-1250kw |

| Capacity |

1120-6813t/h |

| Core Advantages |

Annular cavity laminated crushing |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

III. Core Advantages of Large Rotary Crushers

1. Excellent Processing Capacity and Continuous Operation

Large rotary crushers can achieve a processing capacity of thousands of tons per hour, supporting continuous feeding and crushing operations. This efficient operating mode matches the high-intensity mining pace of modern mines, ensuring the stable operation of the entire production line.

2. Excellent Particle Shape Control Capability

Through optimized crushing chamber design and precise operating parameter control, large rotary crushers can produce products with excellent particle shape. This cubic-shaped aggregate has better compressive strength and stability, and is of higher value in construction and infrastructure projects.

3. Good Adaptability and Reliability

Modern large rotary crushers are manufactured with heavy-duty design and high-quality materials, capable of adapting to various harsh working conditions. The equipped intelligent control system can monitor the equipment's operating status in real time, provide timely warnings of potential faults, and ensure long-term stable operation of the equipment.

IV. Application Case: Mobile Crushing Solution for a Granite Mine

We provided a complete mobile crushing solution including a large rotary crusher for a large granite quarry, achieving significant results.

Project Challenges: The quarry needed to process high-hardness granite, but the original equipment had insufficient processing capacity, frequent downtime for maintenance affected production progress, and the fixed production line could not adapt to changes in the mining face.

Solution: We configured a mobile crushing station equipped with a large gyratory crusher, heavy-duty vibrating feeder, and multi-layer screening system, forming a closed-loop crushing process.

Implementation Results: The equipment achieved an hourly processing capacity of 1500 tons, and the product particle size fully met the requirements of highway construction standards. The mobile design allowed the equipment to follow the mining face, reducing material transfer distance, and increasing overall production efficiency by more than 40%. The intelligent monitoring system enabled preventive maintenance, and equipment availability reached 95%.

V. Recommended Related Equipment

To fully utilize the performance of large rotary crushers, we recommend the following supporting equipment:

Heavy-duty plate feeder: Ensures uniform and continuous supply of stone to the crusher, avoiding no-load or overload operation, and improving equipment utilization and lifespan.

Mobile or Semi-Mobile Design: The crusher is mounted on a crawler or wheeled mobile chassis, or uses a modular semi-mobile design, improving production flexibility and adapting to different working conditions.

Complete Screening and Recirculation System: Equipped with multi-layer vibrating screens and return conveyors, forming a closed-loop system to ensure that the final product particle size meets the requirements and improves resource utilization.

VI. Frequently Asked Questions (FAQ)

FAQ 1: What types of stone are suitable for large rotary crushers?

Answer: Large rotary crushers are particularly suitable for processing medium-hard and harder stones, such as granite, basalt, and quartzite. For materials with lower hardness or higher viscosity, equipment selection and parameter adjustment need to be made based on their specific characteristics. Our engineers will recommend the most suitable equipment configuration based on your stone characteristics.

FAQ 2: How to choose between mobile and stationary large crushers?

Answer: The choice depends on several factors. For large mines with long mining cycles and concentrated stone reserves, stationary equipment may be more economical. However, for small and medium-sized mines or various project sites where the mining face changes frequently and flexible mobile operation is required, mobile large rotary crushers have significant advantages. We offer a variety of configuration options that can be customized to your specific needs.

FAQ 3: What aspects should be paid attention to in equipment maintenance?

Answer: The maintenance focus of large rotary crushers is on the crushing chamber liners, transmission system, and lubrication system. It is recommended to regularly check the wear of the liners and replace them in time to ensure crushing efficiency and product particle size. Maintaining good lubrication is key to extending the equipment's lifespan. Modern equipment is usually equipped with automatic lubrication and condition monitoring systems, which can significantly reduce maintenance difficulty and costs.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!