Overview & Technical Analysis of Vertical Roller Mills

| Key Words | Vertical Roller Mill Price & Cost Analysis |

|---|---|

| Product Name | Vertical Roller Mill |

| Feed Size | 0-38mm |

| Motor Power | 185-1000kw |

| Capacity | 10-120t/h |

| Core Functions | The crushing and grinding action of the rollers. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

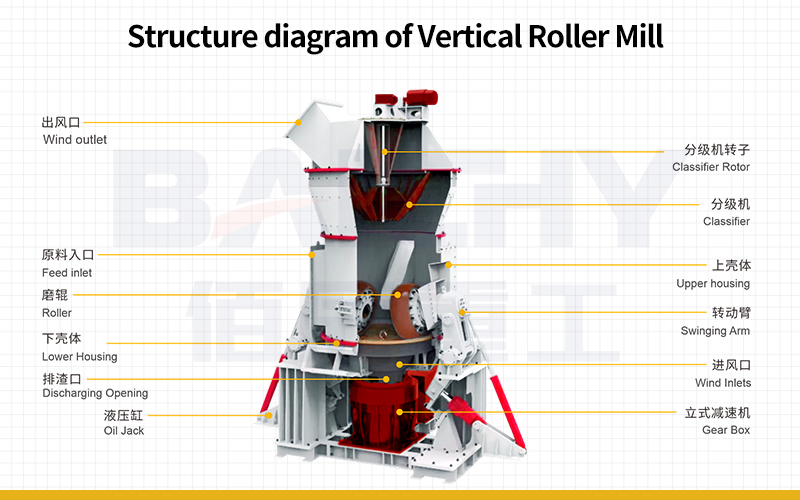

Key Components Influencing Performance & Cost

-

Grinding Rollers & Table: Made from high-chromium alloy or similar wear-resistant materials. The design (e.g., conical, cylindrical) and material quality significantly impact wear life and maintenance costs.

-

Drive System: The power and type of reducer (e.g., planetary gearbox) and motor are major cost factors, determining the mill's capacity and stability.

-

Classifier: A high-efficiency dynamic classifier is crucial for achieving precise product fineness and flexibility, affecting both product quality and system energy consumption.

-

Hydraulic System: Provides the grinding pressure. A robust and precise system ensures stable operation and optimal grinding efficiency.

-

Control System: Modern, automated PLC control systems enhance operational ease, safety, and optimize performance, representing a valuable part of the investment.

Advantages: Why VRM is Worth the Investment

-

High Grinding Efficiency & Lower Energy Consumption: VRMs consume 30%-50% less energy than ball mills for the same output, as grinding occurs directly on the table under pressure rather than through inefficient impact and friction.

-

Superior Drying Capacity: Hot gases can be introduced directly into the mill housing, allowing it to handle materials with moisture content up to 15-20%, eliminating the need for a separate dryer.

-

Compact Plant Design & Small Footprint: Its vertical structure occupies significantly less space than a horizontal ball mill system, reducing civil construction costs.

-

Lower Noise & Environmental Friendliness: Enclosed operation results in lower noise levels (approx. 80-85 dB) and reduced dust emission compared to traditional mills.

-

Ease of Maintenance & Operation: Key wear parts like rollers can be serviced or replaced without removing other major components, reducing downtime.

What Determines the Vertical Roller Mill Price? Key Factors

1. Capacity & Model Size

2. Material to be Processed

3. Product Fineness Requirements

4. Level of Automation & Configuration

5. Brand & Manufacturer's Expertise

Case Study: Real-World Application & Value

Results:

-

Energy Savings: Specific power consumption reduced by over 40%.

-

Output Increased: Achieved consistent target fineness with 25% higher output.

-

ROI: The client recovered the investment through energy savings in less than 3 years.

This case illustrates how the higher initial price of a VRM was strategically justified by massive operational savings.

Related Recommended Equipment

1. Jaw Crusher

2. Bucket Elevator

3. Intelligent Control System

Frequently Asked Questions (FAQ)

Q1: Is a Vertical Roller Mill more expensive than a ball mill system initially?

Q2: What are the main ongoing maintenance costs for a VRM?

Q3: Can you provide spare parts and technical support globally?

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!