Jaw Crusher Manufacturer | Equipment Advantages and Selection Guide

In mining, building materials, and metallurgy, crushing is the first critical step in material handling. Among numerous crushing equipment, the jaw crusher, with its over 100-year history, still firmly holds the top position in the primary crushing stage. This is not accidental, but determined by its irreplaceable technical characteristics and economic efficiency.

As a manufacturer with 20 years of R&D and manufacturing experience, we believe its enduring vitality stems from its minimalist structural philosophy, strong adaptability, and low operating and maintenance costs. It acts as the gateway of the entire production line; its stability and efficiency directly determine the smoothness of subsequent processes.

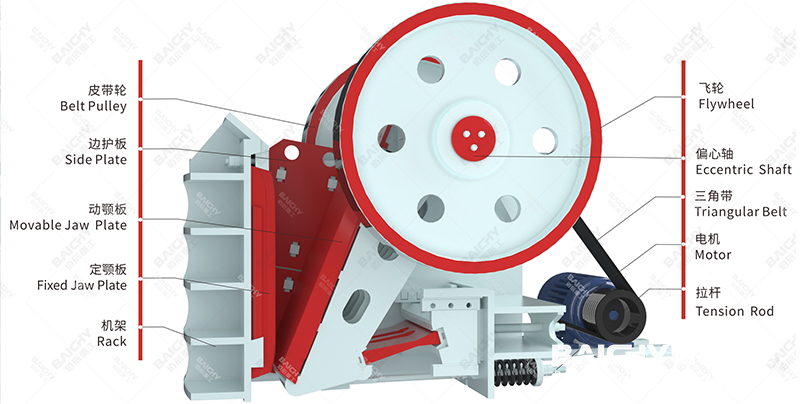

Jaw crusher structure diagram

Core Working Principle: Simplicity Equals Reliability

The working principle of the jaw crusher is intuitive and efficient: the electric motor drives the eccentric shaft via a pulley, causing the moving jaw plate to perform complex periodic reciprocating motion relative to the fixed jaw plate. When the moving jaw plate approaches the fixed jaw plate, the material between the two jaw plates is subjected to enormous compression and bending forces and is crushed; when the moving jaw plate moves away from the fixed jaw plate, the material, already crushed to a size smaller than the discharge opening, falls under its own gravity, thus achieving continuous stone crushing operations. This biomimetic chewing motion is the foundation for achieving efficient crushing.

II. Overview of Jaw Crusher: A Fusion of Classic Design and Modern Technology

Modern jaw crushers are no longer simple mechanical replicas, but rather incorporate numerous new materials, processes, and intelligent elements into a classic structure. From the moving jaw assembly and frame structure to the lubrication system, everything has undergone meticulous design and reliability verification. Our 20 years of experience are reflected in the optimization of every stress concentration point, the precise control of the alloy composition of each jaw plate, and the ultimate pursuit of overall dynamic balance, ensuring stable operation of the equipment under heavy loads and impact conditions.

III. Core Advantages of Choosing Our Jaw Crusher

1. Exceptional Structural Strength and Durability

We use finite element analysis technology to optimize the frame design, manufacture it with high-quality cast steel parts, and reinforce key components (such as bearing seats and ribs) to ensure the equipment can withstand the harshest working conditions and the strongest impact loads, with a service life far exceeding industry standards.

2. Extremely High Crushing Efficiency and Capacity

Through optimized cavity design, the crushing ratio is increased, reducing the probability of material blockage within the cavity and ensuring high material throughput and fast crushing speed. Deep cavity crushing eliminates dead zones, increasing the capacity of jaw crushers with the same power by approximately 15%.

3. Convenient Maintenance and Lower Operating Costs

Modular design for wear parts such as toggle plates and liners allows for quick and easy replacement. A centralized lubrication system ensures effective lubrication of critical friction pairs such as bearings, reducing maintenance time and labor costs. Our jaw crusher jaw plates use a new type of composite high-manganese steel material, improving wear resistance by over 30%, significantly reducing long-term spare parts costs for users.

Jaw crusher structure diagram

IV. Success Case Sharing

Case Study: A Large Granite Quarry in East China

Customer Pain Points: An existing, outdated crushing production line suffered from high failure rates in the coarse crushing equipment, unstable capacity, and frequent maintenance, severely impacting overall output.

- Solution: We recommended and installed the latest model PE-1200x1500 large compound pendulum jaw crusher as the primary crusher.

- Performance: Since its commissioning, the jaw crusher has performed extremely stably, processing over 3000 tons of granite daily without any major downtime. The customer particularly appreciates its excellent throughput and the ultra-long wear life of the jaw plates, reducing overall production costs by over 20%.

V. Recommended Related Equipment (Building a Complete Production Line)

A high-efficiency jaw crusher needs to work in conjunction with subsequent equipment.

We provide complete sand and gravel aggregate solutions:

- Recommended Medium Crushing Equipment: Single-cylinder hydraulic cone crusher - for secondary crushing of medium-hard and harder materials, producing excellent particle shape.

- Recommended Fine Crushing Equipment: Multi-cylinder hydraulic cone crusher or impact crusher - for obtaining high-quality manufactured sand and fine aggregates.

- Supporting Equipment: Vibrating feeder, circular vibrating screen, belt conveyor, dust collection system, etc.

VI. Frequently Asked Questions (FAQ)

1. How is the discharge particle size of a jaw crusher adjusted?

A: This is mainly achieved by adjusting the size of the discharge opening. Our equipment uses a wedge or shim adjustment device, which moves the adjusting seat back and forth mechanically or hydraulically to change the opening distance between the lower ends of the moving jaw and the fixed jaw. Operation is safe, simple, and reliable.

2. What might be the causes of abnormal vibration and noise during equipment operation?

A: Possible causes and troubleshooting sequence: ① Check if the anchor bolts are loose; ② Check if the toggle plate seat is loose from the rear wall of the frame; ③ Check if the bearings are worn or damaged; ④ Check if the flywheel counterweight is unbalanced; ⑤ Check if the jaw plates are loose or broken. Regular inspections are recommended to promptly identify and tighten any loose parts.

3. What is the service life of the jaw plates? What factors affect their lifespan?

A: There is no fixed lifespan for jaw plates; it mainly depends on the hardness and abrasiveness of the material being crushed, the feed size, the feed rate, and the movement trajectory of the moving jaw. Generally, for crushing highly abrasive materials such as granite and basalt, the lifespan is 3-6 months; for crushing medium- to low-hardness materials such as limestone, it can reach over 1 year. Selecting jaw plates with appropriate tooth shape and material, and maintaining a uniform feed, are key to extending their lifespan.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!