Crawler Mobile Jaw Crusher Plant

Overview: Redefining Material Crushing Operations

In today's resource extraction and construction industries, which prioritize efficiency, environmental protection, and low costs, crawler-mounted mobile crushing plants are no longer just simple equipment, but revolutionary production solutions. They integrate core processes such as feeding, crushing, screening, and conveying onto a self-propelled crawler chassis, realizing the concept of "bringing the production line to the material pile." For projects requiring frequent relocation, access to complex terrain, or processing dispersed materials, crawler-mounted mobile crushing equipment is a key investment for improving operational flexibility and reducing overall costs.

Core Advantages: Why is it a revolutionary solution?

Compared to fixed production lines and wheeled mobile stations, crawler-mounted mobile crushing plants offer a series of disruptive advantages that make them stand out in demanding working conditions.

Unparalleled Mobility and Accessibility

The crawler track system provides extremely low ground pressure and powerful driving force, allowing it to easily conquer rugged mountains, muddy pits, slopes, and other complex terrains, and even operate directly on the mining face. This "effortless" accessibility means the equipment can get as close as possible to the material source, completely eliminating the high costs and time wasted on long-distance truck transportation of raw ore in traditional methods.

Rapid Deployment and Extremely Low Installation Costs

After arriving at the job site, the crawler-mounted mobile crusher requires no concrete foundation pouring or complex lifting and assembly. Operators can complete equipment positioning, outrigger adjustment, and other preparatory work in a short time using a remote control, quickly entering production. This not only shortens project startup time from weeks to hours but also significantly reduces initial civil engineering and installation costs.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Integrated Design and Flexible Configuration

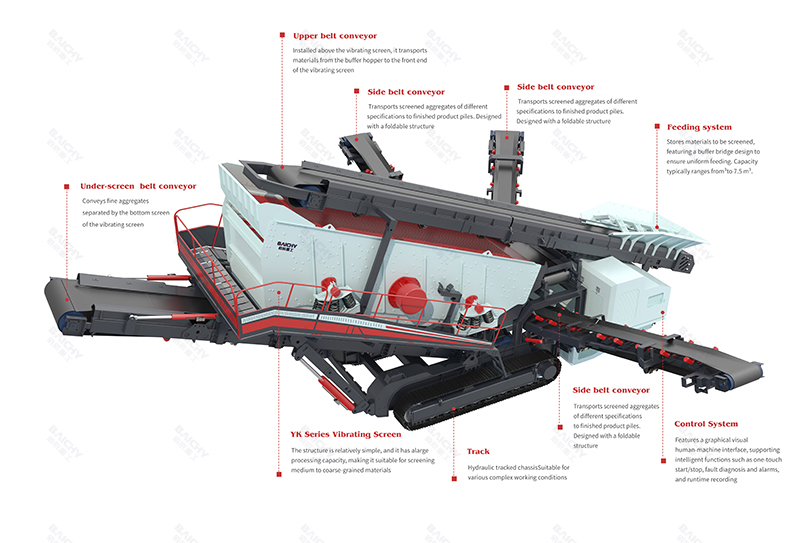

Modern advanced crawler-mounted mobile crushing plants are complete mobile factories. The main unit can be equipped with jaw, impact, cone, or gyratory crushers depending on crushing requirements. It typically integrates pre-screeners, magnetic separators, and return conveyors, forming a closed-loop system that can produce qualified finished products with a single machine. Its modular design also supports flexible pairing with different models of mobile screening plants to form customized production lines. H2 Application Cases: Successful Practices in Multiple Scenarios

Case 1: Short-Process Technology Transformation in a Granite Mine

A large granite mine originally used a "excavator loading - truck transportation to fixed line" model, which was costly. After introducing a crawler-mounted mobile crushing plant equipped with a high-performance cone crusher, primary crushing was carried out directly in the quarry pit, and the crushed material was transported out via a mobile belt conveyor. This transformation reduced transportation costs by over 40% and significantly improved overall production efficiency.

Case 2: On-Site Aggregate Production for Large-Scale Infrastructure Construction

In a hydropower station construction project in a remote area, a large amount of concrete aggregate was needed on-site. The project team used a crawler-mounted mobile crushing and screening unit, utilizing natural stone materials near the construction site for on-site production. The equipment moved flexibly with the construction progress, ensuring the timely supply of aggregates, avoiding long-distance transportation of purchased aggregates, and achieving dual optimization of cost and construction time.

Recommended Equipment: Creating the Perfect Mobile Production Line

Based on your specific material and product requirements, consider the following combinations:

Crawler-mounted mobile jaw crushing plant + crawler-mounted mobile cone crushing plant: A classic hard rock crushing combination, the former for coarse crushing and the latter for medium and fine crushing, producing high-quality aggregates of various specifications.

Crawler-mounted mobile impact crushing plant + crawler-mounted mobile screening plant: Very suitable for processing construction waste, concrete, asphalt blocks, and medium-to-low hardness natural stone materials, producing excellent finished product particle shape.

Crawler-mounted heavy-duty screening plant: As an independent screening unit, it can be combined with any crushing host for fine classification, a powerful tool for increasing product added value.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between crawler-mounted mobile crushing plants and wheeled mobile plants? How to choose?

A1: The core difference lies in the source of mobility and applicable scenarios. Crawler-mounted plants use tracks for movement, offering strong traction and excellent passability, suitable for muddy, rugged, and sloped terrain, and can even be remotely controlled. However, their self-transfer speed is slow, and long-distance transportation requires a flatbed truck. Wheeled plants rely on a truck tractor for towing, moving very quickly on flat ground and for road transfers, but require a higher degree of ground flatness. The selection criteria primarily consider the terrain conditions of the main work site and the frequency of site changes.

Q2: How are the equipment's production capacity and final product particle size controlled?

A2: Production capacity is determined by factors such as the crusher model, material hardness, and feed particle size. Our equipment models cover different needs, from 100 tons per hour to over 600 tons per hour. Product particle size is precisely controlled by adjusting the crusher discharge opening, changing screen specifications, and using a closed-loop circulation system (with a mobile screening plant), easily achieving the production of aggregates of various specifications from 0-5mm to over 40mm.

Q3: As a manufacturer, how do you guarantee the long-term stable operation of the equipment and after-sales service?

A3: We not only provide high-quality, highly reliable crawler-mounted mobile crushing equipment, but also have built a comprehensive service support system. This includes: precise selection recommendations based on project working conditions, professional operation and maintenance training, spare parts warehouses located in key areas, rapid on-site technical service response, and remote intelligent monitoring support based on IoT devices, ensuring that your investment yields maximum returns.

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!