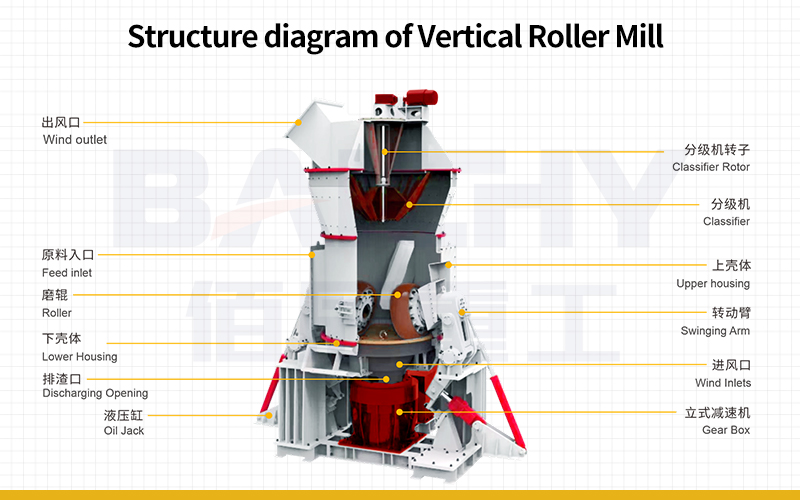

GGBS Vertical Roller Mill

Overview: The Critical Link from Crushing to Grinding

As a professional manufacturer of mobile mining crushing equipment, we understand that crushing is only the first step in the long chain of mineral processing. After being crushed by our equipment, large materials often need to enter the next stage of grinding to meet the requirements for finer particle sizes. In this stage, Chinese vertical roller mills, with their superior performance, have become a key piece of equipment connecting crushing and finished products, playing an irreplaceable role in the global cement, slag, non-metallic minerals, and power plant desulfurization industries.

Analysis of Vertical Roller Mill Advantages: Why Choose Made in China?

Compared with traditional ball mills, modern vertical roller mills have achieved a huge leap in technical principles and energy efficiency. Chinese-made vertical roller mills, in particular, combine the advantages of internationally advanced design and localized manufacturing, becoming synonymous with high cost-effectiveness and reliability.

Detailed Explanation of Core Advantages

Extremely High Grinding Efficiency

The vertical mill uses the principle of material bed grinding, applying enormous pressure to the roller sleeves through a hydraulic system to crush the material. This direct pressure application minimizes energy loss, increasing grinding efficiency by 20%-30% compared to ball mills, and reducing power consumption by 30%-50%. For grinding processes with high energy consumption, this means significant operational cost savings.

Powerful Drying Capability

The vertical mill integrates a hot air furnace interface. Hot air is introduced during the grinding process, allowing for simultaneous drying and grinding of materials with high moisture content (such as slag and coal), achieving "one-stop" processing. This eliminates the need for a separate drying process, simplifying the production line layout, and is particularly suitable for integration with upstream mobile mining crushing stations to form an efficient linkage.

Easily Adjustable Product Fineness

By adjusting parameters such as separator speed and airflow, the fineness of the finished product can be flexibly controlled within a wide range, and the particle size distribution is uniform. This is crucial for producing finished products of various specifications, meeting the precise needs of different downstream industries.

Low Noise and Environmental Friendliness

The equipment operates smoothly, with significantly lower noise levels than ball mills. At the same time, the entire system operates under negative pressure, resulting in minimal dust leakage. Coupled with a high-efficiency bag filter, it easily meets stringent environmental emission standards.

| Key Words |

Dolomite Grinding Equipment |

| Product Model |

Vertical Roller Mill |

| Feed Size |

0-38mm |

| Capacity |

10-120t/h |

| Core Functions |

The crushing and grinding action of the rollers. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Success Story: Perfect Synergy with the Crushing Line

In an EPC project we provided for a large cement group, we fully leveraged the advantages of system integration. The front end of the project was equipped with our independently developed large mobile crushing station for the primary crushing of limestone; the middle section was connected by a belt conveyor; and the back end featured a domestically produced large vertical roller mill for raw material grinding.

Operating Results: This production line achieved seamless integration of the entire process from mining and crushing to grinding. The vertical mill operated stably, the power consumption for raw material grinding was reduced to below 22 kWh/t, and the system output far exceeded the design specifications, helping the customer recover their entire investment within three years, becoming a benchmark green mining project in the region.

Related Equipment Recommendations

Mobile Cone Crusher: Suitable for medium-hard and harder minerals, providing uniform and adjustable feed size for the vertical mill, making it the "best vanguard" for optimizing vertical mill capacity.

Mobile Impact Crusher: Suitable for crushing medium-hard materials, producing well-shaped products, and can be used as a pre-treatment device before the vertical mill, especially suitable for the grinding stage after the resource utilization of construction waste.

Vibrating Feeder and Belt Conveyor System: Ensures stable and continuous material transport from the mobile crushing station to the vertical mill, serving as the lifeline for the efficient operation of the entire grinding system.

Mobile Cone Crusher

Mobile Impact Crusher

FAQ

Q1: As a crushing equipment manufacturer, why is it important to understand vertical roller mills?

A1: Modern mineral processing is a systems engineering. Understanding the technical parameters (such as feed size and moisture content requirements) and advantages of downstream core grinding equipment helps us make better matches in the design and selection of front-end mobile crushing equipment, providing customers with overall solutions from crushing to grinding, creating greater value.

Q2: How does the quality of Chinese-made vertical roller mills compare to international brands?

A2: After decades of technology introduction, assimilation, and innovation, vertical roller mills produced by leading Chinese manufacturers have reached internationally advanced levels in core materials, hydraulic systems, and automation control. Meanwhile, relying on a complete industrial chain and cost advantages, Chinese vertical roller mills offer competitive prices and faster after-sales service response while providing equivalent or even superior performance, resulting in outstanding cost-effectiveness.

Q3: What are the requirements for the feed particle size of a vertical roller mill? How is the front-end crushing usually configured?

A3: The ideal feed particle size for a vertical roller mill is generally below 30-50mm. This usually requires two or even three stages of crushing. The standard configuration is: mobile jaw crusher (primary coarse crushing) + mobile cone/impact crusher (secondary medium and fine crushing). Our mobile crushing equipment combination is flexible and can fully meet the needs of preparing qualified feed for vertical roller mills, and can be implemented in a semi-mobile or fully mobile layout.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!