High-Hardness Rock Road Aggregate Production Line Project in Brazil

Case Study: High-Hardness Rock Road Aggregate Production Line Project in Brazil

Project Overview

• Project Location: Brazil

• Core Requirements: To establish a mobile production line directly at the raw material source to produce high-quality aggregates for local road construction.

• Designed Capacity: 200 tons/hour

• Raw Materials: High-hardness rocks (such as granite, basalt, etc.)

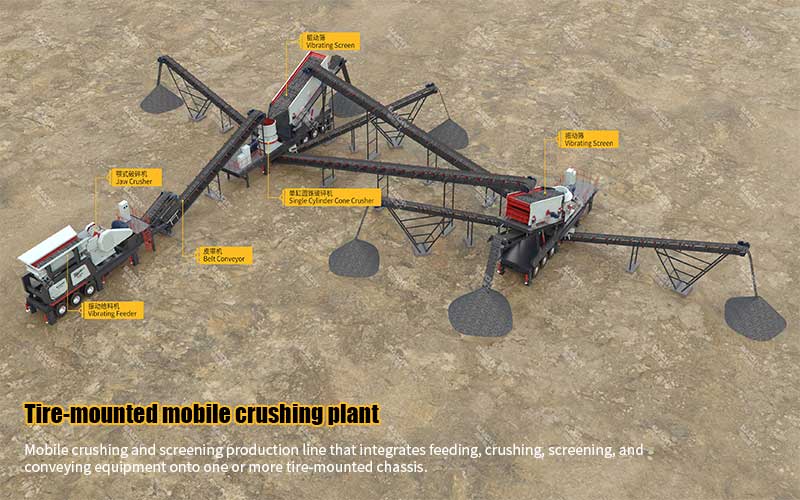

Core Equipment Configuration

Mobile jaw crusher

• Primary Crushing Unit: YDPZ106-1142 Mobile Jaw Crusher

◦ Function: Receives large raw stone blocks for the first stage of high-intensity crushing. The structural characteristics of the jaw crusher enable it to stably process raw materials of varying sizes and extremely high hardness, ensuring the reliability of the production line.

Mobile Cone Crusher

• Secondary and Fine Crushing Unit: YDPZ300-2160 Mobile Cone Crusher

◦ Function: Receives semi-finished materials from the jaw crusher for secondary crushing. The cone crusher utilizes the principle of layered crushing, efficiently crushing and shaping the rock, which is crucial for producing high-quality aggregates with excellent particle shape and low needle-like and flaky content.

In-depth Analysis of Configuration Logic

1. The Golden Combination for "High-Hardness Rock": The combination of a mobile jaw crusher and a mobile cone crusher is the "standard answer" in the crushing industry for handling highly abrasive and hard rocks. The jaw crusher handles the breaking down of the rock (high compressive strength), while the cone crusher handles the shaping (layer crushing). The combination achieves the optimal balance between efficiency and finished product quality.

2. Perfectly Matching the Requirements of "Road Aggregates": Road construction has strict requirements for the compressive strength, abrasion resistance, and particle shape (cubic, low-needle flaky). This combination can stably produce high-specification aggregates that meet various gradations (e.g., 0-5mm, 5-10mm, 10-20mm, 20-31.5mm).

3. Scenario Advantages of the "Mobile" Solution: In countries like Brazil, with vast areas and dispersed projects, mobile production lines require no complex infrastructure and can quickly enter and relocate. They are ideal for direct sourcing from mines, short-term projects, or situations where material locations are not fixed, significantly reducing investment and operating costs.

Simulated Customer Feedback and Analysis

Positive Feedback (Value Demonstration):

1. Excellent Adaptability and Reliability: "Our rock hardness varies considerably, but this equipment (especially the jaw crusher) performed very stably, never experiencing downtime due to feeding or hardness issues, ensuring continuous material supply for the project."

2. Superior Finished Product Quality: "The aggregate produced by the cone crusher has excellent particle shape, with more cubic and fewer needle-like and flaky particles. Our laboratory tests show that the product fully meets and even exceeds the gradation and mechanical performance requirements for road base and surface layers, receiving high praise from the construction team."

3. Significant Benefits of Mobility: "After the material from the first mining area was processed, we quickly relocated both production lines to a new work site 3 kilometers away. This flexibility saved us expensive earthwork transportation costs, an advantage that fixed production lines cannot match."

4. Efficient Capacity Matching: "The two production lines have perfectly matched capacity. The designed capacity of 200 tons/hour was stably achieved during actual full-load operation, meeting our project schedule requirements."

Potential Challenges and Concerns:

1. Wear Parts Consumption Costs: “When processing such high-hardness rock, wear on the jaw plates and cone crusher walls is a major operating cost. We are very concerned about the lifespan and ease of replacement of wear parts, and localized supply and rapid delivery of spare parts are crucial to us.”

2. Reliance on Skilled Operation and Maintenance: “The cone crusher requires maintaining the proper cavity shape and full-bed crushing to achieve optimal results and minimal wear. This requires a certain level of operator experience, and we have provided specialized training.”

3. Initial Investment Considerations: “Although mobile production lines have a higher overall return on investment, the initial equipment purchase cost is higher than that of fixed lines. However, considering the total project lifecycle (excluding infrastructure, transportation, and relocation costs), the return on investment is very satisfactory.”

This configuration (YDPZ106-1142 mobile jaw crusher + YDPZ300-2160 mobile cone crusher) is a precise, efficient, and mature solution for preparing road aggregates from high-hardness rock in Brazil. It perfectly balances the three core requirements of equipment performance, finished product quality, and project mobility, making it a powerful tool to help customers gain a competitive advantage in large-scale infrastructure construction. Positive customer feedback validates the success of the classic configuration logic in practice, while the concern about wear and tear costs is a common issue that requires meticulous management in all high-hardness rock processing projects.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!