Granite is a highly hard rock, so traditional fixed crushing lines require extensive infrastructure. However, local infrastructure in East Timor is limited, and mines are scattered. The 69 mobile crushing station, with its crawler-mounted design, modular structure, and stable production capacity of 100-120 TPH, has become the preferred solution for customers in East Timor.

This article will delve into:

✔ The adaptability of the 69 mobile crushing station in tropical environments

✔ Challenges and solutions for granite crushing

✔ How to optimize production capacity of 100-120 TPH?

✔ The economic advantages of mobile crushing stations compared to fixed production lines

Project Background: Granite Crushing Demand in East Timor

1. Local Market Pain Points

• Scattered mines: East Timor's complex terrain makes transportation and installation of fixed crushing stations expensive.

• Unstable power supply: The 69 mobile crushing station uses a diesel-electric dual-power system, adapting to off-grid environments.

• High temperature and high humidity: The equipment requires corrosion resistance and efficient heat dissipation.

2. Customer Needs

• Capacity requirement: 100-120 TPH, meeting the needs of small and medium-sized quarries.

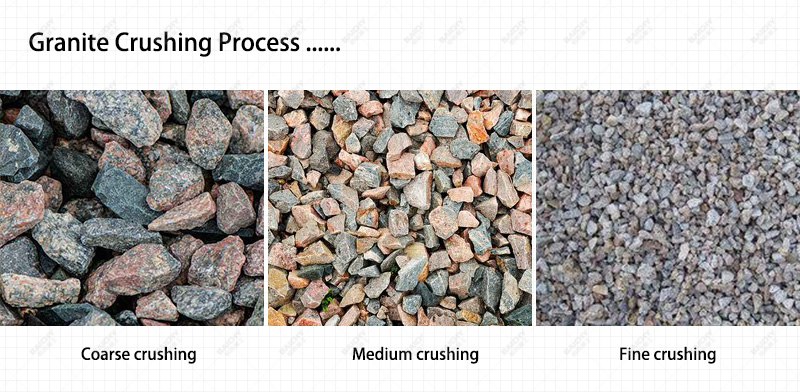

• Finished product specifications: 0-5mm, 5-10mm, 10-20mm (for construction aggregates).

• Equipment flexibility: Frequent site relocation is required to accommodate multiple mining locations.

How does the 69 mobile crushing station overcome granite crushing challenges?

1. Core Configuration Optimization

| Components | Model Selection | Advantages for Granite |

| Jaw Crusher | PE Jaw Crusher | High-manganese steel jaw plates resist high granite wear |

| Cone Crusher | Single-cylinder hydraulic cone crusher | Laminated crushing reduces needle-like particles |

| Vibrating Screen | 3YK1860 double-deck screen | High-efficiency screening, reduced return rate |

| Powertrain | Cummins diesel engine + electric motor | Adapts to Timor-Leste's unstable power conditions |

2. Key Technologies for Stable Capacity at 100-120 TPH

• Intelligent Load Control: Real-time adjustment of crushing chamber pressure via the hydraulic system to prevent overloading.

• Modular Conveying System: Reduces material blockages and ensures continuous production.

• Remote Monitoring: Real-time feedback of equipment operating data, enabling early warning and maintenance.

3. Save over 30% in costs compared to fixed production lines

| Cost Items | Fixed Production Line | 69 Mobile Crushing Station |

| Infrastructure | Requires a concrete foundation | No installation required, ready for immediate use |

| Transfer Time | 7-15 days | Complete within 1 hour |

| Management Required | 5-8 people | 2-3 operators |

| Applications | Large mines | Small and medium-sized mines, construction waste recycling |

Case Study: On-site footage in Timor-Leste

• On-site challenges: High temperature (35°C+), high humidity (80%), and high dust content.

Operational Data:

• Average production capacity: 110 TPH

• Finished product yield: ≥95%

• Continuous operation time: 12 hours/day

Industry Perspective: Are mobile crushing stations suitable for all granite projects?

Suitable for:

✓ Small- to medium-scale production (50-200 TPH)

✓ Multi-site switching needs

✓ Regions with weak infrastructure (such as Southeast Asia and Africa)

Unsuitable for:

✖ Ultra-large mines (requiring 500 TPH+, where fixed lines are more economical)

✖ Extremely low-temperature environments (below -20°C, requiring special hydraulic system protection)

As the global mining industry evolves towards flexibility and low carbon production, the 69 mobile crushing station, with its low investment and high flexibility, is transforming traditional granite crushing models.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)