Configuration Scheme for 180-250 t/h Mobile Limestone Crushing Production Line

Production Line Overview

This is a highly efficient and flexible mobile production line specifically designed for medium-scale limestone processing. Its core advantage lies in its mobility; the equipment can move with the raw material mining face, significantly reducing material transfer distances and site infrastructure costs. It is particularly suitable for operating environments requiring relocation, such as mines, quarries, and building aggregate production.

Production Line Detailed Parameters

• Design Processing Capacity: 180 - 250 tons/hour

• Feed Material: Limestone (Mohs hardness approximately 3, medium hardness, brittle)

• Finished Product Specifications: Typically produces aggregates in various sizes, including 0-5mm, 5-10mm, 10-20mm, and 20-31.5mm. Specific particle sizes can be achieved by adjusting the discharge ports and screen sizes of each stage of the crushing equipment.

• Core Configuration: Mobile Jaw Crusher + Mobile Impact Crusher + Mobile Simons Cone Crusher

• Workflow: Three-stage crushing + two-stage screening (usually integrated into the mobile station)

Application Areas

The high-quality limestone aggregate produced by this production line is widely used in:

1. Commercial concrete plants: For preparing various grades of concrete.

2. Highway and railway subgrade construction: Requires stabilized layer materials with different gradations.

3. Building aggregates: Used for masonry mortar, precast components, etc.

4. Asphalt concrete: Used for high-grade pavement surface layers.

5. Other infrastructure construction.

Equipment Configuration and Process Flow Analysis

This is a classic "three-stage crushing" mobile production line combination, balancing efficiency, finished product particle shape, and operational stability.

1. First Stage Crushing: Mobile Jaw Crusher (Coarse Crushing)

• Function: Responsible for the initial crushing of large pieces of limestone (particle size up to several hundred millimeters) extracted from the mine.

• Advantages: Robust structure, high processing capacity, ideal for primary crushing. Its mobile design allows it to be fed directly from the mining face using a loader, eliminating the need for expensive stationary feeders and long-distance plate feeders.

2. Secondary Crushing: Mobile Impact Crusher (Medium Crushing)

• Function: Receives material from the jaw crusher and performs medium to fine crushing. The impact crusher utilizes impact energy to crush materials.

• Advantages: Produces well-shaped finished particles, mostly cubic, with low needle-like and flaky content, making it ideal for high-standard concrete aggregate. For medium-hardness materials like limestone, the impact crusher offers high efficiency and relatively low energy consumption.

3. Tertiary Crushing: Mobile Simons Cone Crusher (Fine Crushing and Shaping)

• Function: Further crushes and shapes the material after impact crushing to obtain smaller finished products (e.g., 0-5mm, 5-10mm), improving overall output and particle shape uniformity.

• Advantages: Stable operation and long wear part life. The Simmons cone crusher utilizes the principle of layered crushing, making it particularly suitable for processing medium-hard materials like limestone. It effectively reduces operating wear costs and ensures long-term, continuous, and stable operation of the production line.

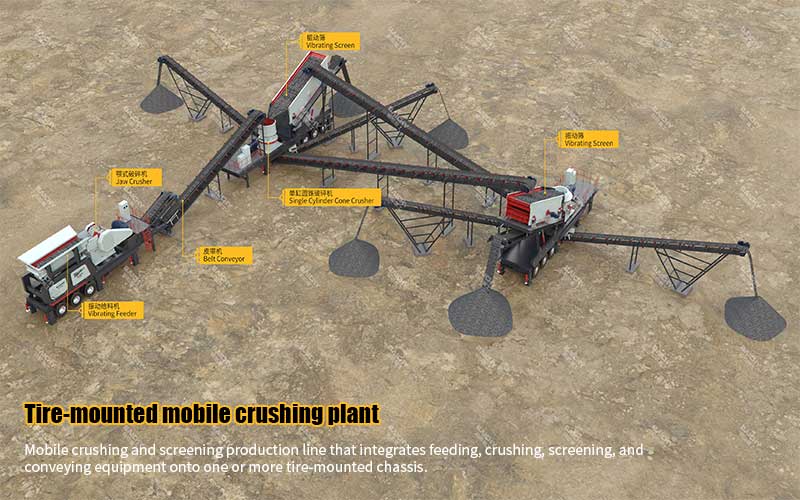

4. Screening and Conveying System

• Each mobile crushing station typically comes equipped with a vibrating screen for pre-screening or closed-loop crushing, ensuring the finished product has the required particle size.

• Mobile stations are connected by heavy-duty belt conveyors to form a complete production line.

Process solution for 3 mobile crushing plants

Production Line Layout and Advantages

• Flexible Layout: The three mobile units can be arranged in a "Z" or "L" shape, flexibly adjusted according to the site terrain. Each unit is self-contained, including feeding, crushing, screening, and conveying functions.

• Convenient Relocation: The entire production line can be quickly moved to a new work location using a tractor unit, restoring production in as little as a few hours, resulting in a rapid return on investment.

• Environmentally Friendly and Efficient: Mobile stations can be equipped with a spray dust suppression system to reduce dust. The integrated design reduces dust and energy consumption caused by material transfer within the site.

The configuration of "mobile jaw crusher + mobile impact crusher + mobile Simons cone crusher" is a highly efficient, mature, and reliable solution for limestone crushing at a capacity of 180-250 tons/hour. It cleverly combines the excellent particle shape of the impact crusher with the operational stability of the cone crusher. While ensuring the quality of the final aggregate product, its mobile flexibility significantly reduces overall operating costs, making it ideal for modern aggregate production projects with fluctuating market demands and frequent site relocations. In actual selection, the parameters of each equipment model need to be fine-tuned based on the specific limestone's mud content, moisture content, and the most important finished product specifications.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!