Granite, a high-hardness stone, often encounters problems during the crushing process, including equipment wear, reduced efficiency, and inconsistent finished product quality. This article will thoroughly analyze the top 10 common problems in granite crushing lines and provide unique solutions to help you optimize production processes, reduce maintenance costs, and extend equipment life.

1. Crusher Blockage - How to Avoid Frequent Downtime?

Cause: The high hardness of granite, uneven feed, or excessive moisture can easily lead to blockage.

Unique Solution:

• Install a vibrating feeder with a pre-screening device to remove oversized or high-mud material.

• Adjust the jaw plate clearance to avoid overload.

• Use a hydraulic cavity clearing system to quickly resolve material jams.

2. Decreased Output - How to Improve Crushing Efficiency?

Cause: Equipment wear, improper discharge port adjustment, or insufficient motor power. Unique Solutions:

• Optimize the crushing chamber design and utilize the laminated crushing principle to improve the crushing ratio.

• Regularly check liner wear to ensure optimal crushing clearance.

• Utilize variable frequency control technology to automatically adjust the speed based on the load.

3. Rapid Equipment Wear - How to Extend Service Life?

Cause: The high hardness of granite causes rapid wear of vulnerable parts such as the jaw plate, impact plate, and hammer.

Unique Solutions:

• Select high-manganese steel or composite wear-resistant alloys to improve impact resistance.

• Use reversible liners to replace worn liners and extend replacement cycles.

• Install an online wear monitoring system to provide early warning and replacement.

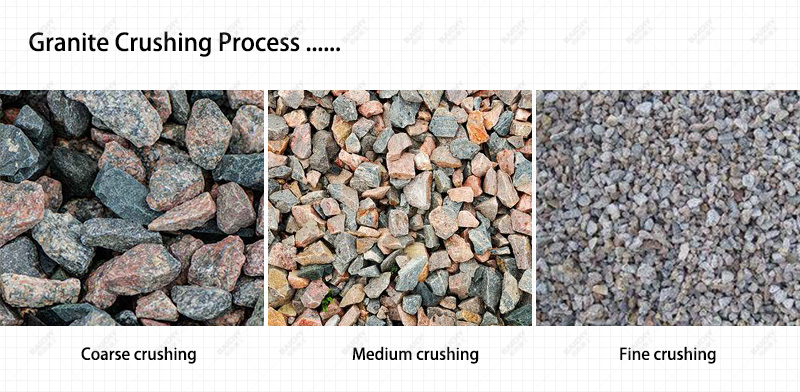

4. Poor Finished Product Particle Shape - How to Optimize Stone Shape?

Cause: Improper crusher selection or an inefficient screening system. Unique Solutions:

• Use a three-stage crushing process (jaw crusher + cone crusher + shaper) to increase the cube ratio

• Adjust the impact plate angle to enhance the impact crushing effect

• Add air separation or water washing equipment to remove needle-like particles

5. Severe dust pollution - How to achieve environmentally friendly production?

Problem cause: The crushing and screening processes generate a large amount of stone dust.

Unique Solutions:

• Use dry mist dust suppression + pulse bag dust collection to reduce PM2.5 emissions

• Enclosed conveyor belt design to reduce dust spillage

• Recycle stone dust to make machine-made sand or building materials

6. Loud vibration and noise - How to reduce environmental impact?

Problem cause: Unstable equipment foundation or worn bearings. Unique Solutions:

• Install rubber shock-absorbing pads and a steel structure base to reduce resonance.

• Use a low-noise motor and silencer to reduce noise by 10-15 decibels.

• Regularly check bearing lubrication to avoid abnormal vibration.

7. Excessive Energy Consumption - How to Reduce Electricity Costs?

Cause: Improper equipment matching or prolonged no-load operation.

Unique Solutions:

• Use a "one-to-many" intelligent control system to adjust equipment start and stop times on demand.

• Upgrade to a high-efficiency, energy-saving motor to reduce reactive power losses.

• Optimize the crushing process to reduce re-crushing.

8. Belt deviation and slippage - How to achieve stable conveying?

Cause: Uneven belt tension or worn rollers. Unique Solutions:

• Install an automatic deviation correction device to adjust belt position in real time

• Use anti-slip patterned belts to increase friction

• Regularly inspect roller bearings to prevent jamming

9. Electrical System Failure - How to Reduce Downtime?

Problem Cause: Unstable voltage or frequent overload protection triggering.

Unique Solutions:

• Install a voltage stabilizer and soft start device to protect the motor

• Use PLC intelligent control to automatically diagnose fault points

• Regularly clean dust from the electrical control cabinet to prevent short circuits

10. High Maintenance Costs - How to Reduce Operating Expenses?

Problem Cause: Frequent replacement of spare parts or inefficient manual maintenance.

Unique Solutions:

• Establish a consumable parts inventory management system to reduce emergency procurement costs

• Implement predictive maintenance technology to detect potential failures in advance

• Train operators to reduce human error

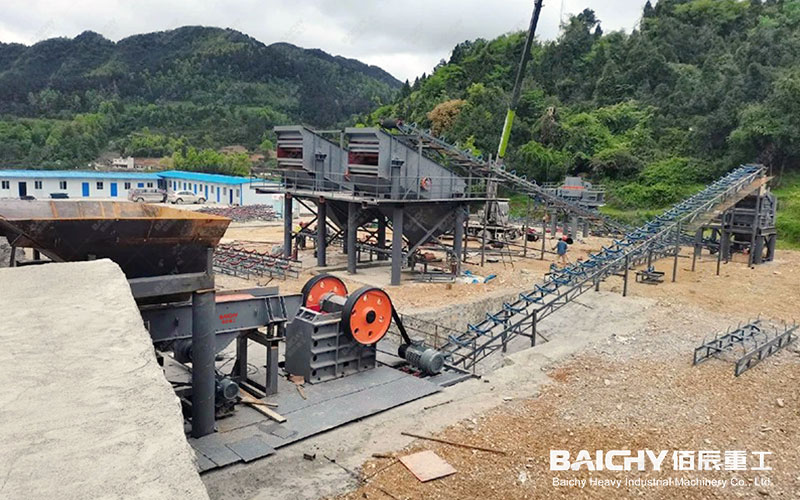

Summary: How to build an efficient and stable granite crushing production line? • Optimize equipment selection (jaw crusher + cone crusher + crusher combination)

• Enhance wear protection (high-manganese steel liner + online wear monitoring)

• Intelligent control + energy-saving transformation (frequency conversion + PLC automation)

• Environmentally friendly dust suppression + noise reduction (dry mist dust removal + vibration reduction design)

• Preventive maintenance (regular inspections + spare parts management)

With the above solutions, your granite crushing line will achieve higher output, lower energy consumption, and longer lifespan, significantly improving economic benefits!

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)