In the fields of mining, building demolition and aggregate production, mobile crushing stations have become the core equipment of modern operations. Faced with the two mainstream types of crawler drive and tire drive, how to choose the equipment that best suits your project needs? This article will deeply analyze the technical characteristics, performance and applicable scenarios of the two to help you make a wise decision.

1. The core advantages of crawler drive mobile crushing station

1.1 Excellent terrain adaptability

The crawler drive system is known for its excellent off-road performance and can easily cope with:

• Steep slopes within 30°

• Muddy and soft working sites

• Rugged mining environment

• Demolition sites with many rocks and obstacles

Typical case: After a granite mine project adopted a crawler mobile crushing station, it could still maintain more than 85% of normal operating time in the rainy season, while traditional tire equipment had only 50% availability.

1.2 Stable working platform

The crawler design brings significant advantages:

• Ground pressure as low as 0.5kg/cm², reducing ground settlement

• The center of gravity is evenly distributed, and the equipment can still operate safely when the inclination is ≤5°

• Strong vibration absorption capacity, extending the service life of the equipment

1.3 Integrated intelligent control system

Modern crawler crushing stations are standardly equipped with:

• Full hydraulic drive system

• Remote monitoring platform

• Automatic leveling function

• Fault diagnosis system

2. Main features of tire-driven mobile crushing stations

2.1 Efficient road mobility

Outstanding advantages of tire-driven equipment:

• The transfer speed can reach 80km/h (trailer required)

• No special transportation procedures are required (in compliance with highway regulations)

• Site switching can be completed within 2 hours

• Suitable for multi-site rotation projects

2.2 Flexible working mode

• Can quickly switch to fixed operation

• Supports a variety of power configurations (diesel/electric)

• Modular design for easy maintenance

3. Key performance comparison analysis

3.1 Comparison of terrain adaptability

| Terrain type | Track rating | Tire rating |

| Flat hardened ground | ★★★★ | ★★★★★ |

| Loose sand | ★★★★★ | ★★ |

| Wet mud | ★★★★★ | ★★ |

| Slippery mud | ★★★★★ | ★★ |

| Stoney slope | ★★★★ | ★★ |

| Urban construction site | ★★★ | ★★★★ |

3.2 Comparison of production efficiency

Under standard working conditions (medium hardness materials):

• Crawler type: average processing capacity can reach 95% of the nominal capacity

• Tire type: average processing capacity is 85-90% of the nominal capacity

The difference mainly comes from:

• Better feeding stability of crawler type

• Fewer mobile adjustments

• More uniform material flow

4. Selection decision guide

| Situations where crawler type is suitable: | Tire-type is preferred in the following scenarios: |

| The working terrain is complex and changeable | Frequent site transfers (more than once a month) |

| The project cycle exceeds 2 years | Small and medium-sized projects with limited budgets |

| Handling high-hardness materials (such as granite and basalt) | Mainly handling low and medium hardness materials |

| The equipment stability is extremely high | The working ground is hardened |

| The equipment position needs to be fine-tuned frequently | Need to take into account road transportation needs |

5. Industry application examples

Case 1: Construction waste resource project (crawler type)

In a certain urban renewal project:

• Processing capacity: 1.5 million tons of construction waste

• Advantages of using crawler mobile station:

• Crushing directly at the demolition site

• Adapt to concrete blocks containing steel bars

• Maintain 70% operating efficiency on rainy days

• Return on investment: Equipment cost recovered in 9 months

Case 2: Sand and gravel aggregate production project (tire type)

A regional aggregate supplier:

Five quarries operate in rotation

Reasons for choosing tire type:

• Transfer 2-3 times a month

• The site is hardened

• Need to respond quickly to different customer needs

• Operation results: Transportation costs reduced by 40%

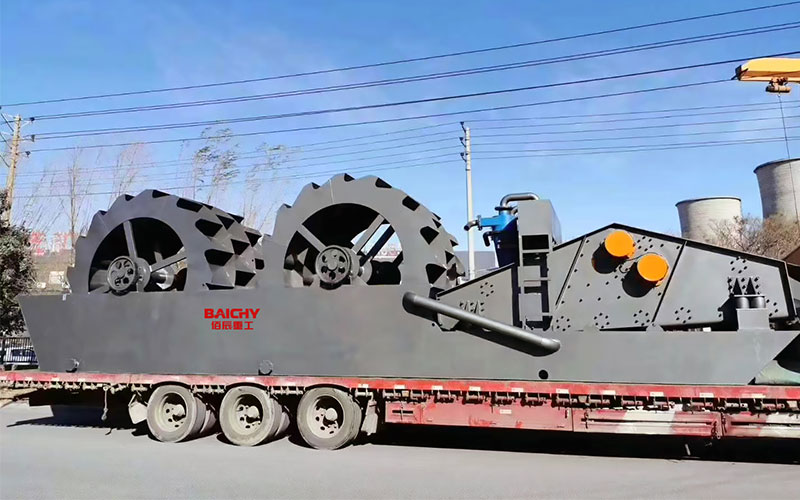

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)