Tracked Impact Crusher Shipped to the Philippines

The tracked impact crusher has been loaded and shipped to the Philippine mining area! This is more than just a shipping notification; it's a vivid example of our 20 years of dedicated focus on manufacturing mining crushing and grinding equipment. It signifies that our customized, efficient, mobile crushing solution for our Philippine customer is ready and on its way to its work site. This marks the successful completion of our entire service chain, from needs assessment and solution design to manufacturing and final delivery, and is another solid step in our global delivery network.

What is a Tracked Impact Crusher?

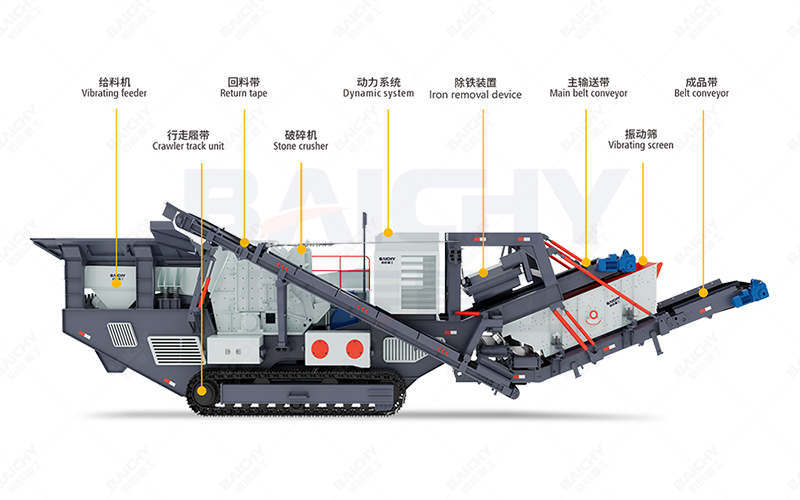

Tracked impact crusher structural diagram

A tracked impact crusher is a highly integrated mobile crushing plant that combines feeding, crushing, screening, and conveying. Its core lies in mounting a high-performance impact crusher on a fully hydraulically driven tracked chassis, giving it excellent mobility and site adaptability. It requires no complex infrastructure installation and can be driven directly to the mining face, construction waste dumps, and other raw material locations, achieving a highly efficient crush wherever the raw material is operation mode.

Why Choose a Tracked Impact Crusher? Core Advantages Analysis

As a manufacturer with 20 years of experience, we deeply understand our customers' pursuit of ultimate equipment reliability and production efficiency. These core concepts were incorporated into the design of our tracked impact crusher from the outset.

1. Unparalleled Mobility and Site Adaptability

The tracked walking mechanism allows it to move smoothly on rugged, soft mining ground, and even climb slopes, easily handling complex and varied mining terrain. No tractor unit is needed for relocation; a one-button switching of driving modes significantly saves time and transportation costs.

2. Rapid Production and Reduced Operating Costs

After arriving on site, the equipment can be put into production almost immediately, eliminating the lengthy infrastructure construction time required for traditional production lines. The integrated design also reduces connection losses between equipment, improves overall energy efficiency, and significantly reduces operating costs in the long run.

3. High-Efficiency Crushing and Excellent Finished Particle Shape

Utilizing the impact crushing principle, it is ideal for medium and fine crushing of medium-hard and lower-hard materials. The finished material has a cubic particle shape with low needle-like and flaky content, making it an ideal choice for high-quality aggregates and meeting the stringent requirements of the Philippines for construction and infrastructure materials.

4. Environmental Protection and Intelligent Operation

The equipment can be equipped with advanced dust removal and noise reduction devices to meet environmental protection requirements. Simultaneously, the integrated intelligent control system can monitor the equipment's operating status in real time, enabling remote fault diagnosis, ensuring stable operation, and reducing maintenance difficulty.

Successful Cases and Global Applications

Our tracked mobile crushing plants have served more than 30 countries and regions worldwide. For example, in a large granite mine in Southeast Asia, two of our tracked impact crushers were used in conjunction to achieve an annual production target of 3 million tons of high-quality aggregates. The excellent particle shape of the output material was highly welcomed by local ready-mix concrete plants. In a short-term mining project in Australia, the equipment's rapid deployment and withdrawal capabilities saved the client more than 40% of the total project cost. The equipment shipped to the Philippines is specifically designed to address the unique working conditions of its dispersed mining areas and frequent relocation.

Related Product Recommendations

In addition to tracked impact crushers, our full range of mobile crushing and screening equipment can meet your perse needs:

• Tracked Jaw Crusher: As the primary crusher, it processes large pieces of raw ore, preparing for subsequent crushing stages.

• Tracked Cone Crusher: Suitable for medium and fine crushing of high-hardness materials, it features strong wear resistance and economical operating costs.

• Tracked Screening Station: It can be flexibly combined with various crushers to achieve precise material classification and improve the overall efficiency of the production line.

Frequently Asked Questions (FAQ)

Q1: What materials are suitable for crushing with a tracked impact crusher?

It is ideal for crushing medium-hard and lower hardness materials such as limestone, bluestone, and dolomite, and is also widely used in the recycling of construction waste. For high-hardness materials such as granite and basalt, a mobile combination solution of a jaw crusher and a cone crusher is recommended.

Q2: How is the equipment's fuel consumption and ease of maintenance?

Our equipment uses energy-efficient engines and hydraulic systems, resulting in a lower fuel consumption rate compared to similar products. The centralized maintenance points make key components easily accessible, and routine maintenance such as lubrication and screen replacement is very convenient. It is also equipped with a remote intelligent management system that can provide early warnings of potential problems.

Q3: Does the equipment have special configurations for the tropical and rainy climate of the Philippines?

Yes, tailored to the climate characteristics of tropical regions like the Philippines, we can provide customized configurations including anti-corrosion coatings, enhanced heat dissipation systems, and high-level protection for electrical components, ensuring the equipment's reliability and durability in high-temperature and high-humidity environments.

Behind every loaded and shipped shipment lies our commitment to our customers and our unwavering dedication to quality. This batch of tracked impact crushers shipped to the Philippines embodies our 20 years of technological accumulation and deep understanding of local working conditions. We look forward to its outstanding performance in the Philippine mining areas, creating exceptional value for our customers.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!