Gypsum, as a key industrial raw material, is widely used in construction, medicine, agriculture, and food processing. With the rapid development of the global construction industry, demand for gypsum powder continues to grow. Mauritania boasts abundant gypsum mineral resources, but due to limited processing technology, many companies still rely on traditional production methods, which are inefficient, energy-intensive, and result in inconsistent product quality.

How can we achieve efficient utilization of gypsum resources?

The integrated gypsum grinding and drying production line is the key to solving this problem! This line integrates crushing, grinding, and drying, boasting a high degree of automation, energy conservation, and environmental protection, making it particularly suitable for gypsum processing in hot, dry regions like Mauritania.

Core Advantages of the Gypsum Grinding and Drying Production Line

1. High Efficiency and Energy Saving, Lowering Operating Costs

• Low Energy Consumption Design: Utilizes an advanced hot air circulation system to reduce heat loss, saving over 30% compared to traditional drying methods.

• Intelligent Temperature Control: Precisely adjusts the drying temperature to prevent overheating and deactivation of gypsum powder, ensuring consistent product quality.

• High Grinding Efficiency: Equipped with a Raymond mill or vertical mill, the fineness is adjustable (80-600 mesh) to meet the needs of various industries.

2. Automated Production, Reduced Human Intervention

• PLC Intelligent Control System: Enables one-touch start and stop, fault alarms, and remote monitoring, reducing manual operation complexity.

• Continuous Production: Fully automated processes, from raw material crushing to finished product packaging, improve production efficiency and are suitable for large-scale processing.

3. Adaptable to Mauritania's Climate

• High-Temperature-Resistant Design: The equipment utilizes special materials to withstand Mauritania's hot and dry environment, minimizing equipment wear and tear.

• Dust and Moisture-Proof: The enclosed structure prevents dust intrusion, ensuring the purity of the gypsum powder.

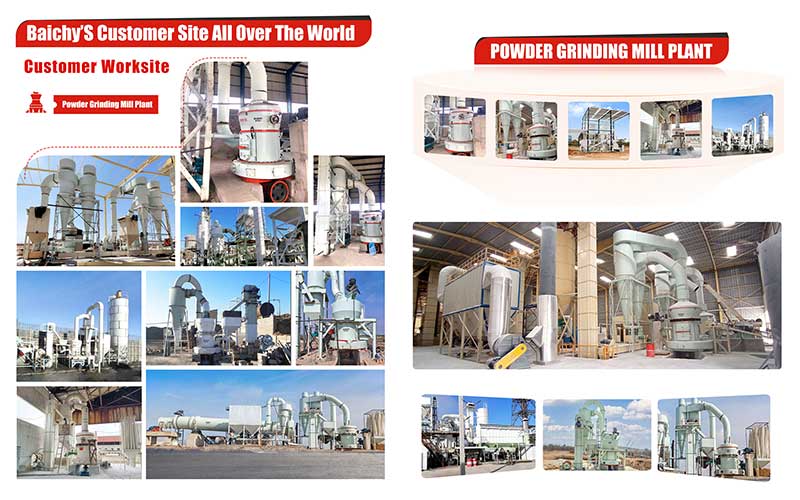

Gypsum Grinding + Drying Production Line Application Case in Mauritania

Case Study: Gypsum Processing Plant Upgrade Project in Mauritania

Original Problem: Traditional natural drying methods are inefficient, significantly affected by weather, and result in unstable moisture content in the finished product.

Solution: Introducing an integrated gypsum grinding and drying production line, enabling 24-hour continuous production.

Results:

• Production capacity increased to 50 tons/day, with the moisture content of dried gypsum powder ≤1%.

• Energy consumption reduced by 40%, and labor costs by 50%.

• The finished product quality meets international standards and is exported to the European market.

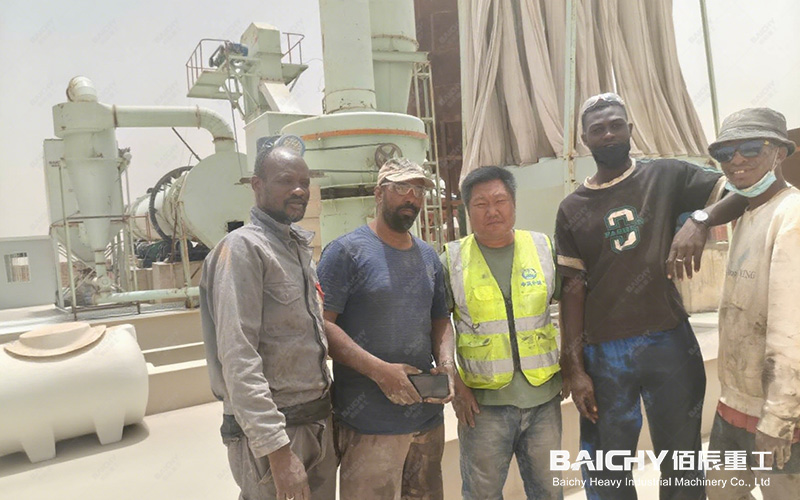

"Since introducing this production line, the quality of our gypsum powder has significantly improved, and customer orders have tripled!"

- Customer feedback from Mauritania.

How to choose the right gypsum grinding and drying equipment?

1. Select the model based on production capacity requirements.

• Small production line (5-20 tons/day): Suitable for start-ups or small-scale operations.

• Medium production line (20-100 tons/day): Suitable for medium-sized gypsum plants, offering high cost-effectiveness.

• Large production line (100 tons/day+): Suitable for mining groups or export-oriented enterprises.

2. Focus on equipment materials and durability.

• Grinding mill: Made of high-manganese steel or alloy steel for high wear resistance.

• Dryer: Made of stainless steel liner for high-temperature corrosion resistance.

3. Choose a supplier with local service support.

Mauritania's industrial base is relatively weak, so it's recommended to choose a one-stop supplier that provides installation and commissioning, technical training, and after-sales maintenance to ensure long-term stable operation of the equipment.

Gypsum grinding and drying production lines not only address the pain points of traditional processing methods but also help Mauritanian companies improve their competitiveness and expand into the international market. If you're looking for an efficient, energy-saving, and automated gypsum processing solution, please contact us for free technical consultation and customized solutions!

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)