Raw material grinding is a critical step in the cement production process, and its efficiency and quality directly impact the performance and energy consumption of the final product. In recent years, vertical grinding mills, with their unique design and significant efficiency advantages, have gradually become the preferred main equipment for raw material grinding systems. This article will delve into the operating principle, core advantages, and applicable scenarios of vertical cement mills, providing a reference for industry colleagues.

1. Operating Principle of Vertical Grinding Mills

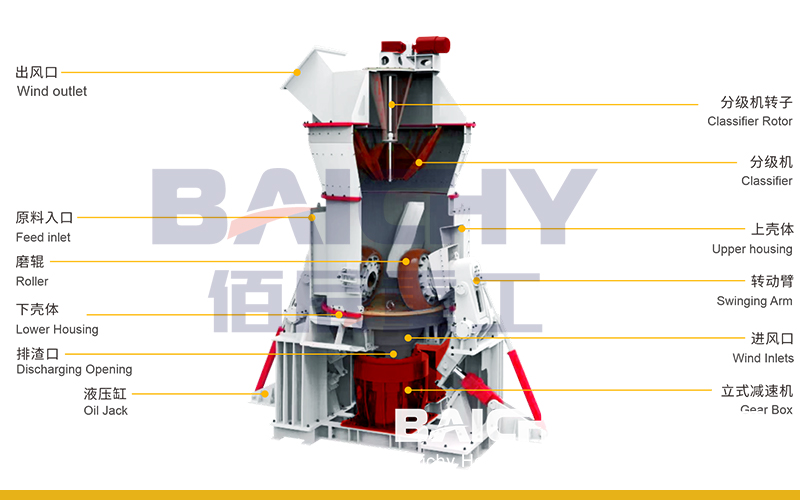

Vertical grinding mills utilize the material bed grinding principle. Material enters the center of the grinding disc through a central feed pipe and is moved toward the edge of the disc by centrifugal force. Grinding rollers, driven by a hydraulic system, crush and shear the material. The pulverized material rises under the influence of airflow and enters the classifier. Fine powder is discharged and collected by the airflow, while coarse powder falls back to be reground. This closed-loop system enables efficient, controllable, and continuous production.

2. Six Core Advantages of Vertical Cement Mills

1. Significantly Reduced Energy Consumption

Compared to traditional ball mills, vertical grinding mills can reduce energy consumption by 30%-50%. Because it utilizes a material bed grinding principle, it boasts high energy efficiency, avoiding energy loss from collisions between steel balls and the liner in a ball mill.

2. High Grinding Efficiency

The vertical mill integrates crushing, grinding, drying, and classifying functions. Its integrated high-efficiency classifier allows for the timely separation of qualified fine powder, preventing over-grinding and increasing production efficiency by approximately 40%.

3. High Drying Capacity

It can process raw materials with a moisture content of up to 15%. Utilizing kiln exhaust gas as a heat source, it achieves simultaneous grinding and drying, saving investment in separate drying equipment.

4. Small Footprint

The vertical mill's compact structure reduces floor space by over 50% compared to ball mill systems, significantly reducing plant height requirements.

5. Low Noise and Environmentally Friendly

Operating noise levels are below 80 decibels, significantly lower than the 100-110 decibels of a ball mill. The fully enclosed system also minimizes dust escape. 6. Easy Maintenance and Low Operating Costs

The grinding roller can be removed from the machine for maintenance, minimizing roller sleeve lining replacement time and minimizing downtime. Wear parts have a long lifespan, and power consumption per ton of grinding is only 4-6 kWh.

III. Key Points for Vertical Mill Selection and Application

When selecting a vertical cement mill, consider the following factors:

• Raw material characteristics: grindability, particle size, and moisture content

• Product requirements: fineness and specific surface area

• System compatibility: synergy with the preheater and calciner

• Equipment manufacturer: technical maturity and local service capabilities

Currently, mainstream vertical mill models include the LRM, TRM, and HRM series, with processing capacities ranging from 50 to 600 t/h. Selection can be tailored to the scale of the production line.

IV. Actual Application Results and Data Support

After adopting a vertical mill on a 5,000 t/d production line, raw material power consumption was reduced from 27 kWh/t to 14.5 kWh/t, saving approximately 6 million kWh annually. Furthermore, the product achieves stable fineness (80μm sieve residue <12%) and uniform composition, laying a solid foundation for stable kiln system operation.

Vertical mills, with their energy-saving, high-efficiency, integrated, and intelligent features, have become the preferred solution for raw meal grinding in modern cement plants. With the advancement of intelligent control technology, vertical mill systems are evolving towards unmanned operation and predictive maintenance, providing core equipment support for the cement industry's green transformation. It is recommended that vertical mill systems be prioritized for new production lines, while existing ball mill systems can also be upgraded as needed.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)

Further reading:

How To Choose A Suitable Industrial Grinding Mill?

Which Is Better Cement Vertical Roller Mill Or Ball Mill?

What Are the Differences between Dry and Wet Type Ball Mill?