According to the description from our Mexican client, they are setting up a quarry and need a complete crushing and screening production line. Their core requirements include:

1. Jaw Crusher Front-End Feeding System

• A feeder is needed that matches the size of the 80×50 cm jaw crusher.

• The feeder should be able to feed the jaw crusher evenly and continuously to ensure crushing efficiency.

2. Jaw Crusher Back-End Conveying System

• A vibrating chute (vibrating feeder) is needed after the jaw crusher.

• Used to transport the coarsely crushed material to the next stage of crushing equipment.

3. Secondary/Tertiary Crushing System

• A cone crusher with an inlet diameter of 120 cm is needed.

• Used for secondary crushing of the coarse material produced by the jaw crusher.

4. Screening and Grading System

• A vibrating screen with dimensions of approximately 400×150 cm is needed.

• Used to screen the crushed material into different sizes of finished products.

Feeder + Jaw Crusher - Customer Site

Feeding System Configuration

Vibrating Feeder (ZSW490×110)

For the feeding requirements of the 80×50 cm jaw crusher, we recommend the ZSW490×110 vibrating feeder. This equipment uses a double eccentric shaft exciter structure, with a feeding capacity of 250-380 t/h, a feed size of ≤300 mm, and a motor power of 15 KW. Its advantages include:

• Variable frequency speed control allows for precise adjustment of the feeding volume, preventing jaw crusher jamming.

• Adjustable bar spacing provides pre-screening functionality, allowing fine materials to directly enter the finished product.

• Wear-resistant liners are made of high-manganese steel, extending the service life by more than 30%.

Vibrating Chute (Bar Vibrating Feeder GBZ1200×L)

The vibrating chute after the jaw crusher uses a GBZ1200×L bar vibrating feeder. The length is determined according to the site layout (usually 3-10 meters), and the motor power is 7.5-18.5 KW. The equipment features:

• Heavy-duty plate structure, capable of withstanding the impact of large materials

• Pre-screening function to remove fine materials directly into the finished product, reducing the load on the jaw crusher

• Hydraulically adjustable discharge opening for easy operation

Limestone crushing production line at a customer's site.

Crushing System Configuration

Jaw Crusher (PE750×1060)

As a primary crushing equipment, the PE750×1060 jaw crusher has a feed opening of 630mm, a processing capacity of 72-130 t/h, and a motor power of 90KW. Equipment features:

• Deep cavity crushing design, large crushing ratio, and uniform product particle size

• Hydraulically adjustable discharge opening with an adjustment range of 95-165mm

• Movable jaw made of high-manganese steel for strong wear resistance

Cone Crusher (PYB1200)

A PYB1200 cone crusher is configured to meet the requirement of a 120 cm feed opening diameter. This equipment has a feed particle size of ≤145mm, a processing capacity of 110-168 t/h, and a motor power of 132KW. Technical advantages:

• Single-cylinder hydraulic system for convenient and accurate discharge opening adjustment

• Large crushing ratio, low energy consumption, and excellent finished product particle shape

• Suitable for secondary crushing operations, with adjustable output particle size

Crushing and screening equipment at a customer's site.

Screening System Configuration

Vibrating Screen (2YK2460)

A 2YK2460 vibrating screen with a size of 400×150 cm is used, with a screen surface size of 2.4×6.0 meters and 2 layers of screen mesh. Equipment Features:

• Processing capacity: 200-900 t/h, screening efficiency ≥85%

• Uses rubber spring vibration damping, noise level below 75 decibels

• Screen mesh made of polyurethane material, with a lifespan 3 times longer than metal screens

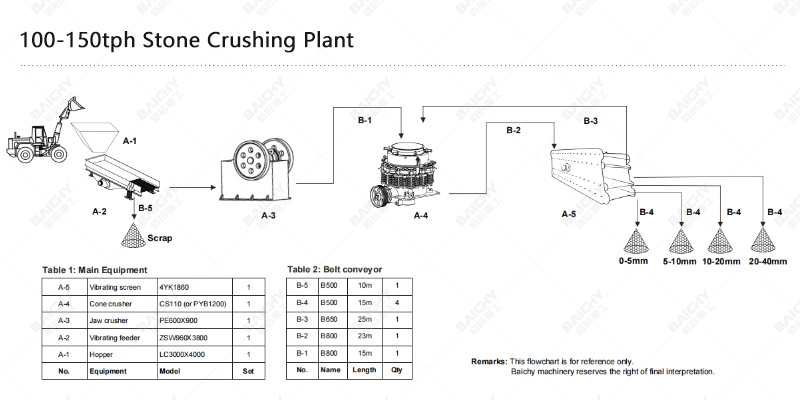

Layout diagram of a 100-150 tph limestone crushing production line

Complete Production Line Process Flow

Process Flow:

Stone → Vibrating Feeder → Jaw Crusher (Coarse Crushing) → Vibrating Trough → Cone Crusher (Medium Crushing) → Vibrating Screen → Finished Product

Technical Parameters:

| Processing Capacity | 100-150 t/h |

| Feed Size | ≤630mm |

| Finished Product Specifications | 0-5mm, 5-10mm, 10-20mm, 20-31.5mm |

| Total Installed Power | Approximately 300KW |

Equipment Advantages and Features

Technical Advantages

High Efficiency and Energy Saving

• Optimized cavity design, crushing efficiency increased by more than 20%

• Intelligent hydraulic system control, energy consumption reduced by 15%-30%

• Closed-loop circulation system, material can be crushed to below 20 mesh in three cycles

Stable and Reliable

• Core components use wear-resistant materials such as high-manganese steel and high-chromium alloy

• Bearings use imported brands, extending service life by 50%

• Hydraulic protection device, automatic overload protection to prevent equipment damage

Intelligent Control

• PLC control system, achieving one-button start and stop

• Remote monitoring function, real-time monitoring of equipment operating status

• Fault diagnosis system, early warning of potential faults

Environmental Performance

• Fully enclosed design, dust emission concentration ≤10mg/m³

• Noise control ≤75 decibels, meeting environmental requirements

• Wastewater recycling, achieving zero discharge

Successful Cases

Case 1: Philippines 1000 tons/hour Quarry Project

• Configuration: 2 PE1500×1200 jaw crushers + 2 PF1820 impact crushers + 4 2YK3072 vibrating screens

• Finished Product: High-quality crushed stone aggregate (5-10mm, 10-20mm, 16-31.5mm)

• Operating Performance: The equipment ran continuously for 180 days without downtime, and the finished product pass rate was ≥98%.

Case Study 2: Mexico 300 tons/hour Granite Production Line

• Configuration: CH250 single-cylinder cone crusher + 2 HP200 multi-cylinder hydraulic cone crushers + PF1320 impact crusher

• Finished Product Specifications: 1-5mm, 5-10mm, 10-20mm, 20-30mm, 30-40mm

• Operating Performance: Stable output of 350 tons per hour, equipment failure rate <3%

Case Study 3: Zhejiang Jiaotou Haixin Mining Project

• Configuration: CJ1500 jaw crusher + 4 SC360S single-cylinder cone crushers

• Processing Capacity: 1500 t/h

• Operating Performance: Actual capacity reached 1700 t/h, exceeding expectations, with excellent finished product particle shape.

Crushing Production Line Investment Suggestions

Investment Budget

The total investment for a quarry production line with a capacity of 100-150 tons per hour is approximately 1.5-3 million RMB (excluding civil engineering), including:

• Equipment purchase cost: 1-2 million RMB

• Installation and commissioning costs: 0.1-0.2 million RMB

• Supporting equipment (conveyors, dust removal, etc.): 0.2-0.4 million RMB

• Spare parts and tools: 0.1-0.2 million RMB

Return on Investment

• Construction period: 2-3 months

• Investment payback period: 1-2 years (calculated based on sand and gravel price of 30-50 RMB/ton)

• Annual profit: 1.5-3 million RMB (based on annual output of 300,000-500,000 tons)

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.