Symons Cone Crusher

I. Overview of Cone Crushers

Cone crushers are indispensable key equipment in mining, building materials preparation, and other fields, specifically designed for the medium and fine crushing of hard materials such as ores and rocks. With their advantages of strong crushing capacity, high working efficiency, low energy consumption, minimal dust emission, uniform product particle size, and stable and reliable operation, they can continuously produce high-quality finished aggregate, and are widely used in modern industrial production.

II. Working Principle and Structural Composition

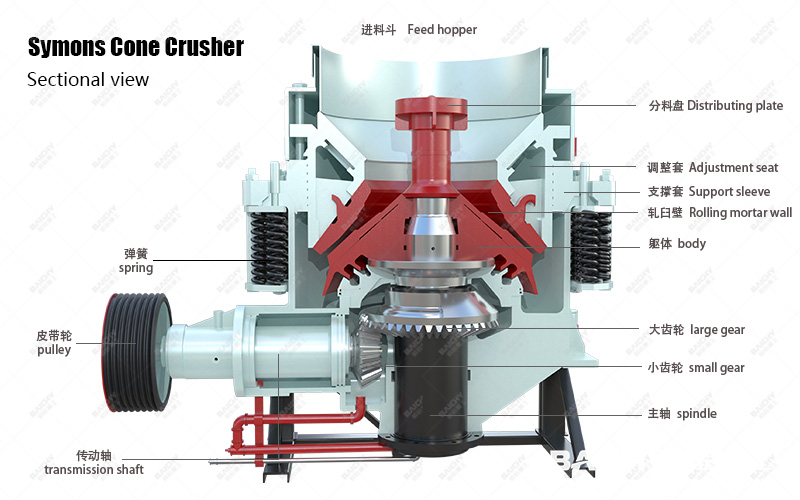

symons cone crusher Sectional view

Working Principle

The working principle of a cone crusher is based on the eccentric gyratory motion of the moving cone around a fixed point. The electric motor drives the eccentric sleeve to rotate through a transmission device. The moving cone, driven by the eccentric shaft sleeve, performs a rotating and swinging motion. The section where the moving cone approaches the stationary cone becomes the crushing chamber, where the material is crushed by multiple compressions and impacts between the moving and stationary cones. When the moving cone leaves this section, the material that has been crushed to the required particle size falls under its own weight and is discharged from the bottom of the cone.

Core Structural Components

The main structure of a cone crusher typically consists of key components such as the frame, eccentric sleeve, main shaft, moving cone (including the crushing wall), stationary cone (including the crushing liner), transmission device, hydraulic system, lubrication system, and electrical control system. The moving cone, driven by the rotation of the eccentric sleeve and constrained by the main shaft, performs a complex gyratory motion, forming a gradually narrowing crushing chamber together with the stationary cone.

III. Technical Advantages and Performance Characteristics

1. High-Efficiency Crushing Capacity

The cone crusher adopts the layered crushing principle. The material forms a dense layer in the crushing chamber, where particles are compressed and ground against each other. This not only improves crushing efficiency but also effectively improves the product particle shape, resulting in more cubic particles and enhancing the quality and market value of the finished aggregate.

2. Excellent Sealing and Dustproof Design

Advanced sealing technologies, such as labyrinth seals and positive pressure dust prevention, effectively prevent dust from entering critical parts (such as bearing housings), significantly reducing lubricating oil contamination, extending the service life of bearings and wear parts, and simultaneously reducing environmental pollution from dust.

3. Convenient Maintenance Performance

The cone crusher adopts a modular design concept. Core wear parts such as the crushing wall and mantle are designed as independent modules, eliminating the need to disassemble the entire component during replacement, thus shortening downtime and reducing maintenance difficulty and costs.

4. Energy Saving and Environmental Protection

The optimized crushing chamber design and matched dynamic parameters result in higher energy utilization efficiency, effectively controlling energy consumption per unit of product. Compared with traditional crushing equipment, it can save 15-30% of energy.

Cone crusher site

IV. Application Case Studies

Case Study 1: Inner Mongolia Iron Ore Crushing Project

In the Baotou iron ore project in Inner Mongolia, the XCMG XGY1500 multi-cylinder hydraulic cone crusher successfully overcame the challenge of crushing high-hardness iron ore. The equipment operates stably for 20 hours a day, with a single machine processing capacity of 300-350 tons per hour, easily achieving a daily production target of 6000 tons. The finished product qualification rate exceeds 75%, far exceeding the industry average.

Case Study 2: Simandou Iron Ore Project

Baichy cone crushers successfully won the bid for the Aluminum Corporation of China's Simandou Iron Ore Crushing and Processing Project. Simandou iron ore is the world's largest and highest-quality undeveloped iron ore deposit. The project has an initial annual production capacity of 120 million tons, which may reach 150 million tons in the future. The cone crusher is responsible for fine crushing in this project, handling raw ore with high moisture content (≥8%), and the finished product requires high output and high fine particle content (P100≤12mm, P80≤6.3mm).

Case Study 3: Hebei Laiyuan Tailings Treatment Project

In the Hebei Laiyuan Jiheng Mining's 6 million tons per year solid waste comprehensive treatment project, Baichy Heavy Industry's HPC series multi-cylinder hydraulic cone crusher is responsible for medium and fine crushing operations, with a designed hourly output of 1200 tons. This project transforms waste tailings into high-value resources. The crushed aggregate products include 0-4.75mm manufactured sand, 5-10mm, and 10-24mm high-quality aggregate materials. The particle shape fully meets relevant national standards and can be directly used for construction aggregate and subsequent dry magnetic separation operations.

V. Equipment Selection and Recommendation

Single-Cylinder Hydraulic Cone Crusher

The single-cylinder hydraulic cone crusher has a simple structure, long service life, and high reliability. It integrates discharge opening adjustment and overload protection functions, simplifying the structure and enhancing reliability. Each specification has different cavity types to meet different crushing and feeding/discharging requirements. All maintenance is performed from the top, making operation simple and maintenance convenient.

Multi-Cylinder Hydraulic Cone Crusher

The multi-cylinder hydraulic cone crusher features a large stroke, high speed, and layered crushing characteristics, making it suitable for processing materials with high hardness and strong abrasiveness. Compared to traditional cone crushers, its capacity is increased by more than 30%, meeting large-scale processing needs. The hydraulic system provides overload protection; when unbreakable foreign objects enter the crushing chamber, the hydraulic system can smoothly release the impact force to protect the main machine and return to the original discharge opening after the foreign object passes through.

VI. Frequently Asked Questions (FAQ)

FAQ 1: What precautions should be taken for daily maintenance of a cone crusher?

Answer: Daily maintenance should focus on the following aspects:

• Lubrication system: Check the oil level and oil temperature every shift to ensure the lubrication system is functioning properly.

• Fastener inspection: Check the foundation bolts, liner bolts, and other fasteners weekly for looseness.

• Liner wear: Regularly check the wear of the crushing wall and mantle. Replacement is required when the wear exceeds 50% of the original thickness.

• Sealing device: Check that the dust seals are intact to prevent dust from entering the lubrication system.

• Electrical system: Keep electrical components clean and regularly remove dust.

FAQ 2: What should I do if the cone crusher experiences abnormal vibration?

Answer: Abnormal vibration may be caused by the following reasons:

• Loose foundation: Check if the anchor bolts are loose, and retighten them to the specified torque using a torque wrench.

• Unbalanced cone: Check if the cone liner is worn evenly; if not, replace it with a new liner.

• Bearing damage: Check if the main shaft bearings are worn, corroded, or poorly lubricated.

• Uneven material loading: Check if the feeding is uniform, and adjust the feeding device to ensure that the material enters the crushing chamber evenly.

FAQ 3: What are the reasons for decreased output and coarser particle size in a cone crusher?

A: The main reasons for decreased output and coarser particle size include:

• Liner wear: Severe wear of the crushing wall and mantle requires timely replacement.

• Oversized discharge opening: Check if the discharge opening adjustment device is loose and readjust it to the appropriate size.

• Uneven feeding: Unstable or uneven feed rate; adjust the feeding device to ensure uniform feeding.

• Insufficient hydraulic system pressure: Check if the hydraulic station pressure is normal, and repair or replace faulty components.

VII. Key Maintenance Points

Daily Maintenance (per shift/day)

• Clean dust and oil stains from the equipment surface.

• Check the oil level and temperature of the lubrication system.

• Check the wear of the belts.

• Check if fasteners are loose.

Regular Inspection

• Weekly inspection: Check belt wear and lubrication filter pressure difference.

• Monthly inspection: Measure the discharge opening size and liner wear.

• Annual inspection: Disassemble and inspect the wear of the main shaft copper bushing and the aging of hydraulic system seals.

Lubrication System Maintenance

• Change oil after the first 500 hours of operation, and then every 2000 hours.

• Clean the oil tank and filter element when changing the oil.

• Use lubricating oil that meets the requirements (such as L-CKD220 heavy-duty gear oil).

VIII. Safety Operation Procedures

Personnel Safety Protection

• Wear safety helmets, safety shoes, and safety glasses during operation.

• When entering the crushing chamber for maintenance, hang a Do Not Start warning sign, and at least two people must be present.

• Wear oil-resistant gloves when handling lubricating grease.

Equipment Safety Protection

• All rotating parts must have protective covers.

• The hydraulic system must be equipped with a safety valve, and the pressure should be adjusted to 1.1 times the working pressure.

• The crushing chamber must have a material level monitoring system to prevent shutdown due to overfilling.

Emergency Procedures

• In case of material blockage, do not use hands or iron rods to forcibly clear the blockage. Stop the machine and use special tools to clear the blockage through the observation hole.

• Fire accident: If a fire is caused by lubricating oil leakage, immediately stop the machine and use a dry powder fire extinguisher (do not use water).

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.