Model 5080 Hammer Crusher - Coal Fly Ash and Bottom Ash Crushing Equipment

The 5080 hammer mill crusher is a specialized equipment designed for crushing coal combustion by-products (fly ash and bottom ash). This model utilizes advanced hammer crushing technology, employing high-speed rotating hammers to impact, shear, and grind the material, achieving efficient crushing. The equipment is suitable for medium-hard brittle materials with a compressive strength not exceeding 100MPa, and can crush large pieces of fly ash and bottom ash in a single pass to a medium-fine particle size (5-50mm), meeting the process requirements for subsequent treatment or resource utilization.

Technical Parameters

Core Performance Indicators

| Parameter Name | Technical Specifications | Remarks |

| Rotor Diameter × Length | 1000×800mm | Standard configuration |

| Feed Particle Size |

≤200mm

|

Maximum processing capacity |

| Discharge Particle Size | ≤45mm | Adjustable range |

| Processing Capacity | 34-45t/h | Standard working conditions |

| Motor Power | 115KW | JR117-6 model |

| Rotor Speed | 980r/min | High-speed impact crushing |

| Overall Dimensions | 3574×2250×1515mm | Compact design |

| Equipment Weight | 6.5T | Total weight of the machine |

Applicable Material Characteristics

The 5080 hammer mill crusher is specifically optimized for the physical characteristics of coal combustion by-products. Fly ash and bottom ash are medium-hard brittle materials with a compressive strength generally not exceeding 100MPa, and the moisture content should be controlled within 15%. The equipment adopts a sealed structure design, effectively solving the problems of dust pollution in the crushing workshop and leakage from the machine body, ensuring a clean production environment.

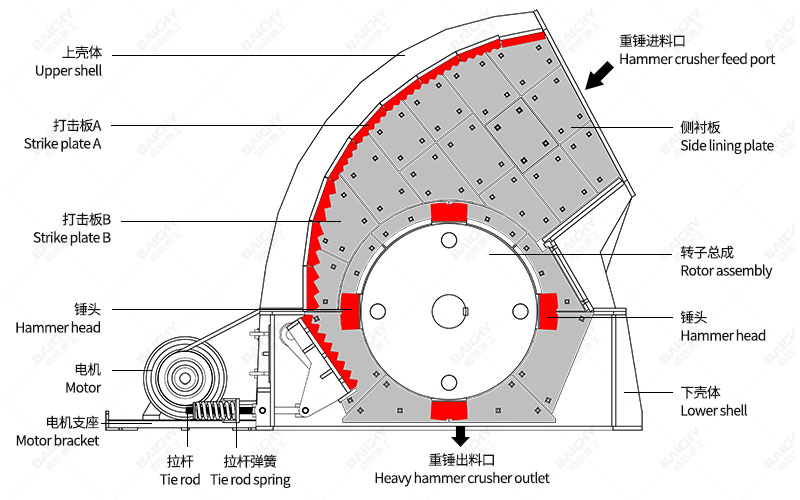

Structural diagram of a heavy-duty hammer crusher

Core Advantages

1. High Crushing Ratio, Multi-purpose Machine

The 5080 hammer mill crusher has a crushing ratio of 10-50, capable of crushing 200mm large pieces of material to a medium-fine particle size of less than 45mm in a single pass, eliminating the need for an additional coarse crushing stage and significantly simplifying the production line structure. This one-step crushing method is particularly suitable for the large-scale processing of fly ash and bottom ash.

2. Simple Structure, Convenient Maintenance

The core structure of the equipment consists of only four parts: motor, rotor (with hammer heads), crushing chamber, and screen plate, without complex transmission mechanisms. The main wear parts are the hammer heads and screen plates, which can be replaced without disassembling complex components; a standard wrench is sufficient. Maintenance time is short (usually 1-2 hours for hammer head replacement), and the technical requirements for maintenance personnel are low.

3. Low Energy Consumption, Controllable Operating Costs

Compared to cone crushers and impact crushers of the same capacity, the 5080 hammer crusher significantly reduces energy consumption per unit of product. The equipment price is usually only 1/3-1/2 of a cone crusher and 1/2-2/3 of an impact crusher, offering a significant cost advantage for projects with limited budgets.

4. Uniform Product Particle Size, Less Over-crushing

Through the triple action of high-speed rotating hammer heads impacting the material + material impacting the crushing chamber liner + screen plate screening, the particle size distribution of the finished product is more concentrated, and there is less over-crushing (excessive fine powder in the finished product). The finished product can be directly used as construction aggregate, road base filler, etc., without the need for additional screening equipment.

Application examples of heavy-duty hammer crushers

Application Cases

Case 1: Southeast Asia Large Power Plant Fly Ash Treatment Project

Project Background: A coal-fired power plant in Southeast Asia produces approximately 100,000 tons of fly ash annually, which needs to be crushed for use in building materials production.

Solution: Two 5080 hammer crushers were configured, using a feeder + hammer crusher + vibrating screen process flow.

Operating Results:

• Processing Capacity: Single unit processing capacity is stable at 40 t/h

• Finished Product Particle Size: ≤45mm, pass rate ≥90%

• Equipment Operating Rate: ≥95%

• Maintenance Cycle: Hammer head service life reaches over 800 hours

Customer Evaluation: The 5080 hammer crusher has a compact structure and is easy to operate, making it particularly suitable for crushing medium-hard materials like fly ash. The equipment runs stably, and maintenance costs are low, fully meeting our production needs.

Case 2: Resource Utilization of Bottom Ash from a Waste Incineration Plant

Project Background: A waste incineration plant in Sichuan produces approximately 50,000 tons of bottom ash annually, which needs to be crushed to less than 30mm for use as raw material for brick making. Solution: Using the 5080 hammer crusher, equipped with a dust removal system and anti-clogging design.

Operating Performance:

• Processing capacity: 35-45 t/h, meeting production needs

• Finished product particle size: ≤30mm, meeting brick-making process requirements

• Equipment adaptability: Operates normally even with material moisture content up to 12%

• Environmental indicators: Dust emission concentration ≤10mg/m³

Customer Feedback: The anti-clogging design of the 5080 hammer crusher effectively solves the problem of bottom ash clogging. The equipment has good sealing performance and significant dust control effect, providing strong support for our environmentally friendly production.

Equipment Selection Suggestions

Selection Criteria

When selecting the 5080 hammer crusher, the following factors should be considered:

1. Material characteristics: Hardness, moisture content, and viscosity of fly ash and bottom ash

2. Processing capacity: Determine the equipment specifications based on production line capacity requirements

3. Finished product particle size: Determine the output particle size according to subsequent process requirements

4. Site conditions: Equipment footprint and installation space limitations

5. Investment budget: Equipment purchase cost, operating and maintenance costs

Recommended Supporting Equipment

To fully utilize the performance of the 5080 hammer crusher, the following supporting equipment is recommended:

• Feeding equipment: Vibrating feeder to ensure uniform feeding

• Conveying equipment: Belt conveyor for continuous material transport

• Screening equipment: Vibrating screen for finished product classification

• Dust removal system: Bag filter to control dust emissions

• Control system: PLC automatic control system for automated production

Frequently Asked Questions (FAQ)

Q1: What are the requirements for the moisture content of the material for the 5080 hammer crusher?

A: The 5080 hammer crusher is suitable for materials with a moisture content of ≤15%. When the moisture content of the material exceeds 15%, clogging is likely to occur, affecting the normal operation of the equipment. It is recommended to dry or air-dry high-moisture materials before crushing to ensure that the moisture content is within a reasonable range.

Q2: What is the replacement cycle for the hammer heads and screen plates?

A: The service life of the hammer heads is related to factors such as material hardness and processing volume, and is generally between 500 and 1000 hours. The replacement cycle of the screen plates is usually 2-3 times that of the hammer heads. It is recommended to regularly check the wear of wear parts and replace them promptly to avoid affecting equipment performance and product quality.

Q3: How to deal with abnormal equipment vibration?

A: Abnormal equipment vibration may be caused by the following reasons: rotor imbalance (uneven wear or detachment of hammer heads), loose foundation, damaged bearings, misalignment of the coupling, etc. Corrective measures include: checking the hammer heads and rebalancing the rotor, tightening the foundation bolts, replacing damaged bearings, and adjusting the coupling alignment. Regular equipment maintenance is recommended to ensure stable operation.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.