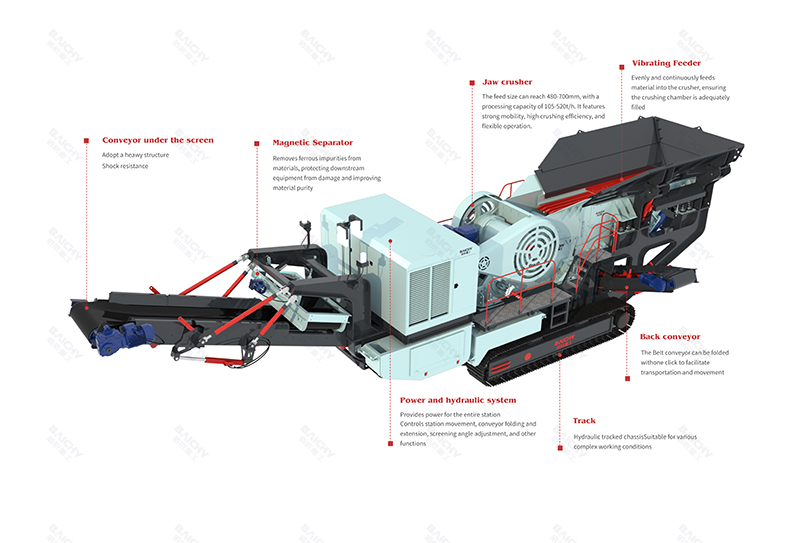

Crawler Jaw Crusher

Overview: What is a Mobile Crushing Plant?

A mobile crushing plant, also known as a mobile crushing and screening unit or portable rock crusher, is a highly efficient piece of equipment that integrates feeding, crushing, screening, and conveying systems onto a mobile chassis. It completely revolutionizes the traditional fixed crushing plant model, which requires complex infrastructure and high relocation costs, bringing the "workshop to the material site" and realizing the advanced production concept of "crushing the raw materials wherever they are." For projects requiring frequent relocation, such as mining, construction waste processing, and road construction, it is a core tool for improving operational efficiency and reducing overall costs.

Core Advantages of Mobile Crushing Plants

Compared to traditional fixed production lines, mobile crushing plants demonstrate unparalleled flexibility and cost-effectiveness.

Significantly Reduced Operating Costs

Savings on Infrastructure and Relocation Costs: No need to build sturdy concrete foundations for the equipment, and eliminates the cost of transporting raw materials over long distances to a fixed crushing line. The equipment can be self-propelled or towed by a trailer, allowing for rapid and low-cost relocation.

Optimized Manpower and Energy Consumption: The integrated and highly automated design reduces the number of on-site operators. Processing materials directly on-site avoids secondary handling of raw materials, significantly reducing fuel consumption.

Unparalleled Flexibility

Strong Site Adaptability: Whether in rugged mining areas or confined urban construction waste processing sites, the mobile plant can quickly be deployed and put into production. Track-mounted mobile plants can even drive directly up slopes and into the heart of the operation.

Flexible Process Configuration: Depending on the customer's requirements for finished product particle size, the plant can be flexibly configured with "screening before crushing" or "crushing before screening" processes, and can form a multi-stage crushing and screening closed-loop system, allowing for one-click adjustment to meet various production requirements.

Environmental Protection and Rapid Deployment

Pollution Control at the Source: Processing materials directly at the mining or demolition site significantly reduces dust, noise, and exhaust pollution generated during transportation, better meeting modern environmental protection requirements.

Ready to Use Upon Arrival, Quick Return on Investment: After the equipment arrives on site, it can be put into production within a few hours with simple leveling, ensuring a fast return on investment, especially suitable for projects with short construction periods and urgent tasks.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Successful Application Cases

Case 1: A Granite Mine

The client had an existing fixed production line, but as the mining face advanced, the increased transportation distance led to soaring costs. We configured a combination of a crawler-mounted jaw crusher mobile station and a crawler-mounted cone crusher mobile station for them. The equipment can operate directly at the edge of the mining platform, and the crushed semi-finished products are transported to the next stage via a mobile belt conveyor. Transportation costs were reduced by 40%, and overall production efficiency increased by more than 30%.

Case 2: Urban Construction Waste Recycling Project

The project was located at a demolition site with limited space and strict environmental requirements. We recommended a combination of a wheeled mobile impact crusher station and a mobile screening station. This equipment is not only highly mobile, but its impact crusher has excellent crushing and shaping effects on materials such as concrete and bricks. The resulting recycled aggregate can be directly used for road sub-base, achieving "turning waste into treasure" and creating considerable economic and environmental benefits.

Equipment Selection Recommendations

Choosing the right mobile crushing station is key to success:

Crawler-mounted mobile crushing station: Uses hydraulic drive, has its own crawler chassis, remote control operation, and strong off-road capabilities, suitable for mines and quarries with complex terrain and harsh working conditions. It is the ultimate solution for "crushing wherever you go."

Wheeled mobile crushing station: Uses a semi-trailer frame and requires a tractor for movement. It has faster transfer speeds and more convenient road travel, especially suitable for projects requiring high mobility and good road conditions, such as multi-site operations and urban construction waste treatment.

Core crusher selection: Jaw mobile crushers are used for primary coarse crushing; cone mobile crushers are suitable for crushing high-hardness materials, pursuing wear resistance and fine particle size; impact mobile crushers are suitable for medium-hardness materials, pursuing good particle shape and high output.

Frequently Asked Questions (FAQ)

1. Can the production capacity of mobile crushing stations meet the needs of large mines?

Absolutely. Modern large mobile crushing stations can achieve a single-unit output of 500-800 tons per hour, or even higher. By using multiple units to form a flexible mobile production line, the total production capacity can fully rival traditional fixed production lines, and it can move synchronously with the advancement of the mining face, always maintaining the optimal transportation distance.

2. How about the equipment's maintenance and durability?

The mobile crushing plant is designed with durability and ease of maintenance in mind. Key components use world-class brands, and the structure is robust. At the same time, features such as centralized lubrication and hydraulic opening mechanisms make daily maintenance simpler. Although the initial investment may be higher than that of a fixed-type equipment of the same model, the savings in overall operating costs result in a higher long-term return on investment.

3. Can we customize specific configurations?

Yes, customization is one of our core strengths. We can tailor the most suitable mobile crushing solution for you based on your specific material characteristics (hardness, moisture content, size), desired finished product specifications, site limitations, and budget. This includes selecting the appropriate crushing host, screening machine model, conveyor length, and auxiliary systems.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!