As a manufacturer of mobile crushing equipment for mines, we understand that the foundation of a production line lies in primary crushing. Choosing the right primary crushing equipment is like laying a solid foundation for the entire crushing process, directly impacting subsequent efficiency, product quality, and operating costs. So, with the wide variety of crushers on the market, what type of crusher is best suited for primary crushing? This article will provide an in-depth analysis and professional advice.

Core Tasks and Equipment Requirements of Primary Crushing

Primary crushing, also known as first-stage crushing, is the first crushing process that materials undergo after blasting in the mine. Its main task is to process large, irregularly shaped raw ore or rocks, crushing them to a size suitable for processing by a secondary crusher (usually below 100-300mm).

An excellent primary crusher must possess the following key characteristics:

Powerful crushing force and high processing capacity: Able to easily handle high-hardness, large-sized raw materials.

Excellent feeding and throughput: Can directly process raw materials containing mud, water, or complex components without pre-screening.

High reliability and durability: Robust structure, capable of continuous and stable operation in harsh mining environments.

Certain flexibility: For mobile production lines, the ease of movement and deployment of the equipment is also crucial.

| Key Words |

Limestone Crushing & Screening Plant |

| Product Model |

Jaw Crusher , Impact Crusher , Heavy Hammer Crusher |

| Feed Size |

≤1300mm |

| Motor Power |

400-1250kw |

| Capacity |

2015-8895t/h |

| Core Advantages |

Annular cavity laminated crushing |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Comparison of the Three Main Types of Primary Crushers

Currently, there are three main types of mobile crushing equipment used for primary crushing: jaw crushers, impact crushers, and heavy-duty hammer crushers. Each has its own advantages and is suitable for different scenarios.

1. Jaw Crusher - The Robust and Durable "Universal Pioneer"

Overview: Jaw crushers use the principle of compression between a movable jaw and a stationary jaw for crushing, and are the most widely used and technologically mature primary crushing equipment.

Advantages Analysis:

Robust structure: Overall steel frame structure, especially suitable for crushing highly abrasive and hard materials, such as granite, basalt, and quartz.

Strong adaptability: Insensitive to material moisture content and mud content, and can handle almost any type of raw ore.

Simple maintenance: Core components are easy to replace and maintain, and have a long service life. Applicable Cases: Large granite quarries, primary crushing of raw ore in metal mines, crushing of concrete blocks in construction waste.

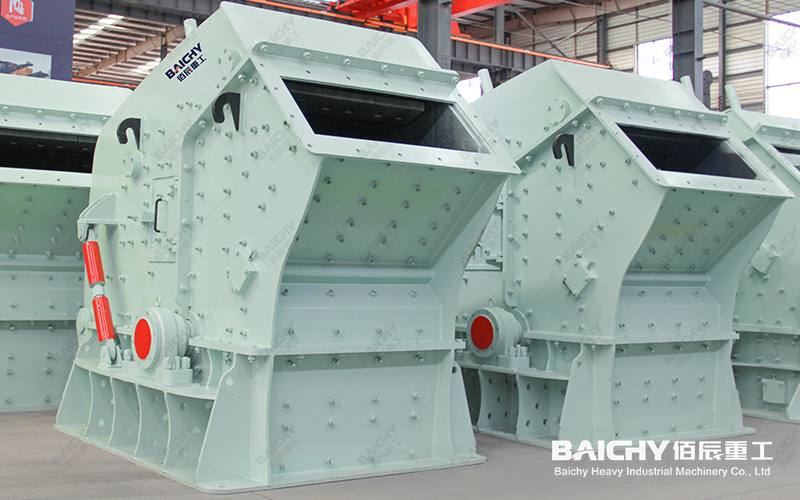

2. Impact Crusher - The High-Efficiency, Versatile Performer

Overview: Impact crushers utilize a high-speed rotating rotor to impact the material, achieving crushing through repeated impacts against the impact plate. They are more commonly used for secondary crushing, but specifically designed heavy-duty models are also suitable for primary crushing.

Advantages:

Excellent product particle shape: The crushed material is cubic in shape, with low needle-like and flaky content, making it the preferred choice for high-quality aggregates.

Combines crushing and shaping: It can shape the material while crushing it, achieving two goals at once.

Applicable Cases: Primary and secondary crushing (single-stage crushing) of limestone and medium-to-low hardness ores where high aggregate particle shape is required.

3. Heavy Hammer Crusher - The Energy-Saving "One-Step" Solution

Overview: The heavy hammer crusher uses the "one-step impact molding" principle, allowing a single machine to crush large materials to medium and fine particle sizes in one go, greatly simplifying the process.

Advantages:

Extremely simple process: A single machine can complete coarse and medium crushing, significantly saving on equipment and infrastructure investment.

Relatively low energy consumption: Under the condition of achieving one-step crushing, it is more energy-efficient than the traditional two-stage crushing process (jaw crusher + cone crusher).

High output: Large processing capacity per unit time.

Applicable Cases: High-volume processing of medium-to-low hardness materials (such as limestone, bluestone, and coal gangue), and limestone crushing in the cement industry.

How to Choose? Our Professional Recommendation

There is no "best" equipment, only the "most suitable" choice. As a manufacturer, we provide you with the following decision-making path:

First Consideration: Material Hardness and Abrasiveness

High hardness, high abrasiveness (such as granite, basalt): Choose a mobile jaw crusher without hesitation. It guarantees reliability and durability.

Medium-to-low hardness (such as limestone, dolomite): A mobile heavy hammer crusher or heavy-duty impact crusher is a more economical and efficient choice, allowing for single-stage crushing and reducing overall costs.

Secondly, consider: Finished product requirements and production capacity

If extremely high demands are placed on particle shape, a heavy-duty mobile impact crusher suitable for primary crushing can be considered.

If you are pursuing ultimate production flexibility and rapid relocation, a wheeled or tracked mobile crushing plant is your best choice, as it can be driven directly to the mining face, saving on truck transportation costs.

Finally, consider: Investment budget and operating costs

Jaw crushers have moderate investment costs, low maintenance costs, and high overall cost-effectiveness.

Heavy hammer crushers may have slightly higher initial investment costs, but the long-term cost savings achieved through simplified processes are very significant.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between mobile and stationary jaw crushers in primary crushing?

A1: The core difference lies in flexibility and initial investment. Mobile crushing plants integrate feeding, crushing, and conveying, eliminating the need for concrete foundations and allowing them to move with the mining face, greatly reducing material transportation costs and site preparation time. They are particularly suitable for mining projects with multiple work sites and short cycles. Stationary crushers are more suitable for large mines with concentrated resources and long lifespans, offering superior stability.

Q2: How is the output particle size of the primary crusher adjusted?

A2: Jaw crushers mainly control particle size by adjusting the discharge opening (adjusting the toggle plate or shims); impact crushers control it by adjusting the rotor speed and impact plate gap; and heavy hammer crushers mainly adjust it by changing the bottom grate gap. Modern mobile crushing plants mostly use hydraulic adjustment, which is more convenient and safer to operate.

Q3: How can primary crushing equipment prevent clogging in wet and sticky material environments?

A3: For wet and sticky materials, we adopt special solutions in equipment design: such as increasing the inclination angle of the feed chute, using a stepped grate feeder to pre-screen fine sticky materials, increasing the passage space in the crushing chamber design, and even equipping impact crushers or heavy hammer crushers with heating devices to prevent adhesion. Choosing a jaw crusher, which is relatively more adaptable to sticky materials, is also an effective strategy.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!