Gyratory Crusher

In modern mining operations striving for higher efficiency and greater throughput, advanced gyratory crushers have become the undisputed core equipment in the primary crushing stage. As a manufacturer specializing in mobile crushing equipment for the mining industry, we understand that a reliable primary crusher is the cornerstone of the entire production process. This article will delve into the technical core, superior advantages, and how advanced gyratory crushers are reshaping the productivity landscape of high-production mines.

| Key Words |

Limestone Crushing & Screening Plant |

| Product Model |

Gyratory Crusher |

| Feed Size |

≤1300mm |

| Motor Power |

400-1250kw |

| Capacity |

1120-6813t/h |

| Core Advantages |

Annular cavity laminated crushing |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

I. In-depth Analysis: Why Do Gyratory Crushers Endure?

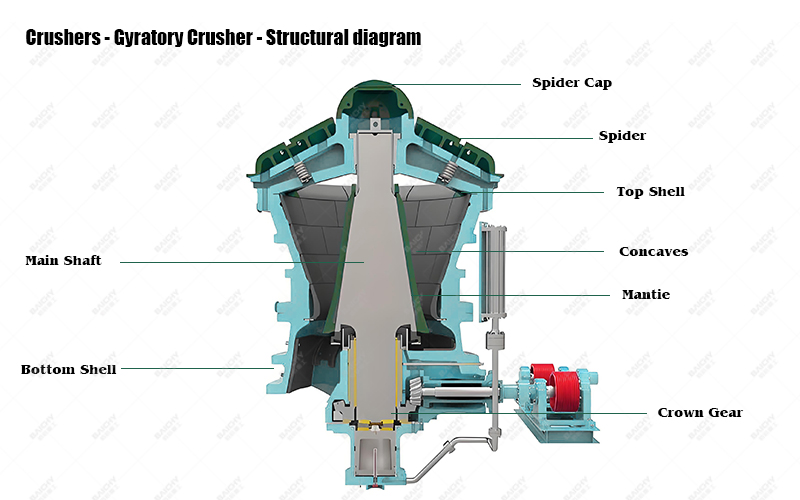

Since its inception, the basic working principle of the gyratory crusher – crushing materials through intermittent compression and bending between the eccentrically rotating cone and the fixed liner – has remained unchanged. However, the term "advanced" reflects comprehensive innovations in its design, materials, and intelligence level.

Modern advanced gyratory crushers are no longer simple mechanical devices. They integrate advanced dynamic simulation design to ensure optimal crushing chamber geometry; utilize high-strength alloy steel and automatic liner wear monitoring systems to extend service life; and are equipped with intelligent control systems for remote monitoring, automatic adjustment, and predictive maintenance. These advancements enable them to handle today's harder and more abrasive ores while meeting stringent requirements for energy efficiency and environmental protection.

II. Overview: What is an Advanced Gyratory Crusher?

An advanced gyratory crusher is a large, continuous primary crushing device primarily used in the first crushing stage of mines and quarries, processing large raw materials directly from the blasting site. Its core characteristic is that the crushing cone performs a gyratory motion, rather than the simple reciprocating motion of a jaw crusher, enabling continuous feeding and high-throughput crushing.

Brief Description of the Core Working Principle

Material is fed from the top inlet and falls into the crushing chamber formed by the moving cone and the fixed liner. As the eccentric sleeve drives the moving cone in a gyratory motion, the volume of the crushing chamber changes periodically, compressing, impacting, and bending the material, causing it to break. The crushed material is continuously discharged from the bottom outlet under gravity.

III. Core Advantages of Advanced Gyratory Crushers

Compared to traditional crushing equipment, advanced gyratory crushers demonstrate multiple decisive advantages in high-production applications:

1. Extremely High Processing Capacity and Continuous Operation

Its unique continuous crushing principle allows for full-chamber loading, achieving "full-feed crushing," resulting in a significantly higher processing capacity per unit of time than jaw crushers of the same size, making it particularly suitable for large-scale, intensive mining operations.

2. Superior Product Particle Shape and Lower Unit Energy Consumption

The particles produced by gyratory crushing are more cubic in shape, with less flaky and elongated particles. At the same time, due to its constant working stroke and continuous crushing, the energy consumption per ton of material crushed is usually lower, saving significant costs over long-term operation.

3. Excellent Reliability and Easy Maintenance

Advanced models adopt a modular design, making key components such as liners quicker and easier to replace. Intelligent lubrication systems and condition monitoring sensors can provide early warnings of potential faults, minimizing unexpected downtime and ensuring the stable operation of the production line.

IV. Application Case: Successful Practice of Mobile Gyratory Crushing Station

The mobile gyratory crushing station solution we provided to a large granite mine perfectly illustrates the power of advanced equipment. This mine faced challenges of large ore particle size, high hardness, and rapid mining face advancement.

Solution: We configured a heavy-duty mobile station equipped with an advanced gyratory crusher, possessing powerful crushing capabilities and excellent mobility.

Results: The mobile station can directly access the mining face, connecting with mining trucks, achieving "crushing as you mine." The single unit's hourly processing capacity exceeds 2000 tons, and the product particle size is consistently below 250mm, creating ideal conditions for downstream secondary crushing. Its intelligent control system makes single-person remote operation possible, significantly improving overall operational safety and efficiency.

V. Related Equipment Recommendations

For building a complete and efficient crushing production line, we recommend considering the following solutions to complement the advanced gyratory crusher:

Heavy-duty plate feeder: Ensures uniform and controlled feeding of large materials to the gyratory crusher, which is a prerequisite for maximizing its production capacity.

Mobile or Semi-Mobile Modular Design: By mounting the gyratory crusher on a modular steel structure or tracked mobile chassis, the time required for mine infrastructure construction can be significantly reduced, and the crusher can move flexibly with the mining face.

Downstream Secondary and Tertiary Cone Crushers and Screening System: These components, combined with the gyratory crusher, form a multi-stage closed-circuit crushing process, ultimately producing high-quality aggregates of various specifications.

VI. Frequently Asked Questions (FAQ)

FAQ 1: How to choose between a gyratory crusher and a jaw crusher for primary crushing?

Answer: The choice depends on capacity, material characteristics, investment, and site conditions. Advanced gyratory crushers excel in processing capacity (usually >1000 tons/hour), continuous production, and product particle shape, making them suitable for large-scale, hard rock mines with fixed or semi-mobile primary crushing. Jaw crushers have lower initial investment, are more flexible to install, and are suitable for medium-capacity applications, situations requiring higher mobility, or processing flaky materials.

FAQ 2: What is the lifespan of the liners in advanced gyratory crushers? Is replacement complicated?

Answer: Modern liners, made of wear-resistant materials such as high-chromium cast iron or manganese steel, have significantly longer lifespans, depending on the abrasiveness of the material. Advanced designs greatly simplify the replacement process; liner replacement can usually be completed quickly using a top-mounted hydraulic device, significantly reducing maintenance time and labor costs.

FAQ 3: Are your mobile gyratory crushing stations suitable for projects requiring frequent relocation?

Answer: Absolutely. Our mobile gyratory stations are specifically designed for frequent relocation, featuring a heavy-duty tracked chassis and integrated power system, allowing for quick site relocation and setup. It integrates all feeding, crushing, and conveying modules, making it ideal for short-term mining projects or operations requiring multiple mining locations.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!