Gyratory Crusher

In modern mining, which prioritizes extreme efficiency and scale, large gyratory crushers have become the indispensable heart of the primary crushing stage in high-production mines. As a professional manufacturer of mobile mining crushing equipment, we deeply understand that for massive projects handling thousands of tons per hour, choosing the right large primary crushing equipment is the primary decision that determines the economics and reliability of the entire production line. This article will delve into how large gyratory crushers have become the core driving force of large-scale production.

Gyratory Crusher PDF, Download ↓↓↓

I. Topic Analysis: Why are large gyratory crushers the inevitable choice for large-scale mines?

When mining projects enter the stage of large-scale, intensive production, the requirements for primary crushing equipment change fundamentally. Large gyratory crushers (typically referring to models with a feed opening width exceeding 1.2 meters and a processing capacity of more than 2000 tons per hour) are designed to meet this demand. Compared to multiple smaller machines operating in parallel, a single large gyratory crusher offers unparalleled economies of scale in terms of footprint, infrastructure investment, operator requirements, and energy consumption per unit of product. It directly receives large chunks of raw ore transported by heavy-duty mining trucks or apron feeders. Its continuous crushing and high throughput characteristics provide stable and ideal feed for downstream secondary crushing and screening processes, acting as the "stabilizing force" for the smooth operation of the entire process.

II. Overview: What is a large gyratory crusher?

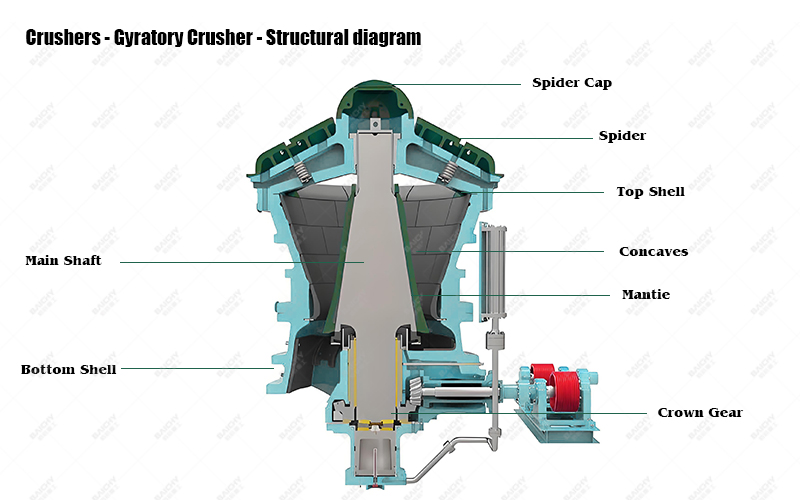

A large gyratory crusher is a heavy-duty crushing equipment based on the principle of gyratory motion, specifically designed for the primary crushing stage in mines and quarries, handling extremely high volumes of blasted raw ore. Its notable features include a huge feed opening (easily accommodating large rocks exceeding 1 meter), a powerful drive system (usually driven by two or more motors), and a robust and durable heavy-duty structure to withstand continuous high-impact, high-load conditions.

Core Design Features

The core of its design lies in optimizing the crushing chamber shape to ensure efficient compression crushing under huge processing volumes. Advanced large gyratory crushers typically feature:

Heavy-duty main shaft and top bearing: Supporting the massive gyrating cone to ensure operational stability. Automatic Control and Adjustment System: Hydraulic adjustment of the discharge opening and tramp iron protection enable precise remote control of operating parameters.

Intelligent Condition Monitoring: Integrated sensors monitor bearing temperature, oil pressure, vibration, and liner wear.

| Key Words |

Limestone Crushing & Screening Plant |

| Product Model |

Gyratory Crusher |

| Feed Size |

≤1300mm |

| Motor Power |

400-1250kw |

| Capacity |

1120-6813t/h |

| Core Advantages |

Annular cavity laminated crushing |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

III. Core Advantages of Large Gyratory Crushers

Investing in a large gyratory crusher brings the following strategic advantages to ultra-large-scale mining projects:

1. Unmatched Processing Capacity and Operating Economy

A single unit can achieve a processing capacity of 3000-10000 tons per hour or even higher, which is unattainable by any other type of primary crusher. It significantly reduces the number of equipment, auxiliary facilities, and operating and maintenance personnel, substantially lowering the fixed operating cost per ton of material.

2. Superior Reliability and High Operating Rate

Designed for continuous, high-intensity 24/7 operation, using the most durable materials and robust design. Through the intelligent predictive maintenance system of the large gyratory crusher, maintenance windows can be scheduled in advance, minimizing planned downtime and ensuring a high operating rate of over 90% throughout the year.

3. Superior Product Particle Shape and Downstream Process Stability

Gyratory crushing produces a uniform particle size with low content of flaky and elongated particles. This not only increases product value but, more importantly, provides a stable and easily processed feed for downstream secondary and tertiary cone crushers, optimizing the efficiency of the entire crushing and screening process and reducing system bottlenecks.

IV. Case Study: Application of Mobile Large Gyratory Crusher in Copper Mining

We provided an innovative solution for a large porphyry copper mine project in South America – a self-propelled mobile crushing plant equipped with a large gyratory crusher.

Challenge: The ore body was dispersed, and the mining face advanced rapidly. Traditional fixed crushing plants required long construction times for foundations and were difficult to relocate, making them unsuitable for the rapidly changing mining face.

Our Solution: We designed a self-propelled module integrating a large gyratory crusher, heavy-duty apron feeder, and discharge conveyor. This equipment does not require large concrete foundations and can move flexibly with the electric shovel using a crawler-type walking mechanism.

Results: The mobile crushing plant successfully increased the raw ore processing capacity to 2800 tons per hour and achieved "crushing at the mining site," eliminating the need for expensive long-distance transportation by mining trucks. The combination of equipment mobility and the high capacity of the large gyratory crusher reduced the overall operating costs of the mine by approximately 18%, significantly shortening the investment payback period.

V. Related Recommendations: Building an Efficient System Centered on Large Gyratory Crushers

To maximize the potential of large gyratory crushers, we recommend the following systems:

Heavy-duty plate feeder: This is the "standard companion" for large gyratory crushers, ensuring uniform and controlled feeding of large and high-volume materials, avoiding uneven loading and blockages.

Semi-mobile or fully mobile solutions: Installing the large gyratory crusher on a modular steel structure or heavy-duty crawler chassis to form a semi-mobile or fully mobile crushing plant. This is especially suitable for deep open-pit mining or mines requiring frequent relocation, significantly reducing initial civil engineering costs and relocation time.

Integrated material handling and electrical control system: A powerful belt conveyor system, dust control system, and centralized intelligent control system are key to achieving efficient, environmentally friendly, and automated operation.

VI. Frequently Asked Questions (FAQ)

FAQ 1: Are the installation and foundation requirements for large gyratory crushers particularly complex?

Answer: Yes, traditional fixed large gyratory crushers require deep, strong concrete foundations to support their immense weight and dynamic loads, making civil engineering complex and time-consuming. This is precisely why semi-mobile gyratory crushing plants have been developed. Our semi-mobile solution uses a prefabricated steel structure base, greatly simplifying on-site installation and shortening the commissioning period.

FAQ 2: Is the large gyratory crusher suitable for processing sticky or wet ore?

Answer: Yes, but special design is required. This can be addressed by selecting a non-clogging cavity shape, increasing the discharge opening, or adding preheating or arch-breaking devices at the feeding end. When selecting a large gyratory crusher, it is essential to provide the manufacturer with detailed information about the material characteristics for targeted optimization.

FAQ 3: What are the main advantages of a single large gyratory crusher compared to operating multiple large jaw crushers in parallel?

A: The core advantages lie in the total cost of ownership (TCO) and process simplicity. A single large gyratory crusher typically has lower energy consumption, maintenance costs, required operators, and footprint compared to multiple jaw crushers achieving the same throughput. Furthermore, a single equipment point is easier to automate and centrally control, resulting in a simpler process and fewer potential points of failure.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!