Crawler Mobile Jaw Crusher

In traditional aggregate production and mining operations, fixed production lines face limitations in terms of site constraints, high infrastructure costs, and transportation difficulties. As projects move to more remote and complex terrains, there is an unprecedented demand for equipment flexibility, mobility, and rapid deployment capabilities. It is against this backdrop that the portable crawler-mounted mobile jaw crusher station emerged. It is not just a piece of equipment, but a mobile production plant integrating crushing, screening, and conveying, completely revolutionizing the operating model.

Equipment Overview: What is a Portable Crawler-Mounted Mobile Jaw Crusher Station?

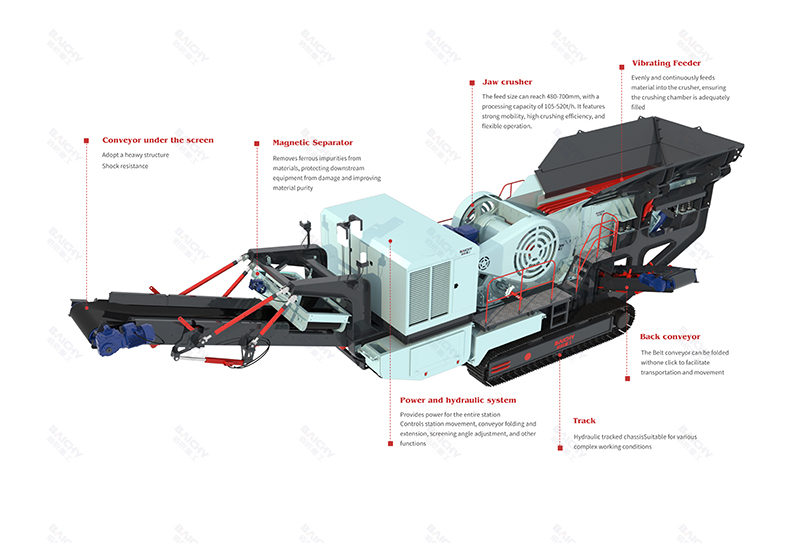

The portable crawler-mounted mobile jaw crusher station is a high-performance crushing equipment integrating feeding, crushing, conveying, and mobility. It adopts a crawler-type chassis, possessing strong terrain adaptability and site flexibility, and can move independently without the need for a tractor. Its core is a high-performance jaw crusher, responsible for the primary or secondary crushing of hard rocks, construction waste, and other materials. The entire machine adopts an integrated design, powered by electricity or diesel, enabling rapid relocation and on-site operation.

Core Advantages: Five Reasons to Choose Our Mobile Jaw Crusher

1. Unparalleled Mobility and Site Adaptability

The crawler system allows it to move freely in rugged, muddy, and steep mining and construction waste sites, even enabling uphill operation, directly reaching the material source, greatly reducing material handling costs and site preparation time.

2. Significant Integration and Rapid Deployment

The equipment integrates a feeder, jaw crusher, discharge conveyor belt, engine, and electrical control system. After arriving at the site, it can be leveled and started for production in just a few hours, producing qualified aggregates quickly, resulting in a rapid return on investment.

3. Powerful Crushing Capacity and High Output

Equipped with a heavy-duty jaw crusher and an optimized crushing chamber design, it has excellent processing capabilities for high-hardness materials such as granite, basalt, and river pebbles, with high single-machine output and excellent finished product particle shape.

4. Significant Operating Cost Savings

The integrated design eliminates the costs of infrastructure and complex steel structures between units. On-site crushing significantly reduces transportation costs for raw materials and finished products. At the same time, the modular design makes maintenance easier.

5. Environmental Protection and Multifunctional Applications

Dust removal and noise reduction systems can be configured as needed. Suitable for various scenarios such as mining, construction aggregate production, construction waste recycling, and road construction, maximizing value through multi-purpose use.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Success Stories: Our Equipment on Global Construction Sites

Case Study 1: Limestone Quarry in the Southwestern Mountains of China

The client faced challenges of narrow sites and steep slopes. Our portable crawler-mounted mobile jaw crusher was deployed directly to the mining face, enabling "crushing as you mine." This transformed raw materials that previously required long-distance transportation into 0-40mm aggregates on-site, increasing production efficiency by 35% and reducing transportation costs by 50%.

Case Study 2: Construction Waste Recycling Project in Southeast Asia

At an urban demolition site, the equipment flexibly moved between different work points, efficiently crushing concrete blocks and discarded bricks and stones. The resulting recycled aggregates were directly used for local road subgrades, achieving resource recycling and earning high praise from the local government.

Related Equipment Recommendations: Building a Complete Mobile Solution

In addition to the core mobile jaw crusher, we can also provide a complete mobile crushing and screening production line:

Crawler-mounted mobile cone crusher: Used for medium and fine crushing, producing finer finished materials.

Crawler-mounted mobile impact crusher: Suitable for medium-hard materials, resulting in better finished product particle shape.

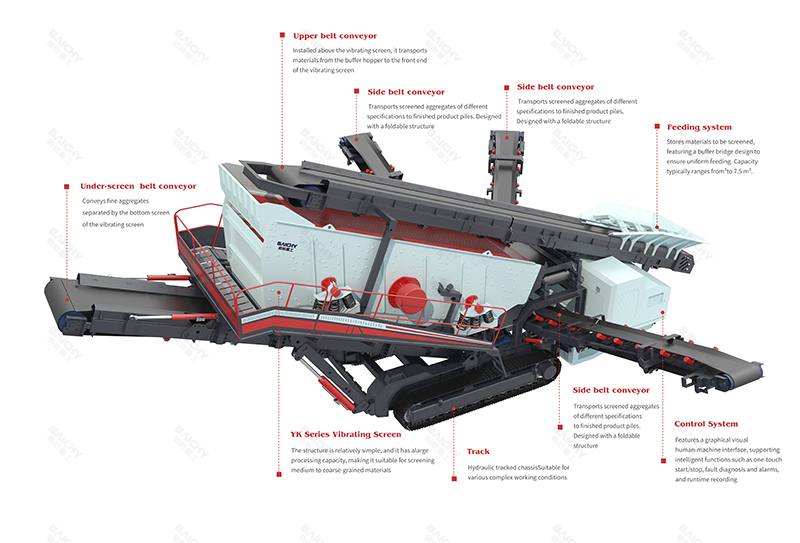

Crawler-mounted mobile screening plant: Works in conjunction with the crusher to achieve precise material classification.

Wheel-mounted mobile crushing plant: Suitable for projects requiring faster movement on roads.

Frequently Asked Questions (FAQ)

Q1: What are the fuel consumption and maintenance costs of the crawler-mounted mobile jaw crusher?

Our equipment uses high-efficiency and energy-saving diesel engines or can be connected to an external power source, and is equipped with an intelligent fuel consumption management system, resulting in superior energy efficiency compared to similar equipment. Modular design and centralized lubrication points make daily maintenance very easy, key components are easily replaceable, and life-cycle maintenance costs are controllable.

Q2: What size of feed material can it handle? What is the maximum processing capacity?

Specific parameters vary depending on the model. Taking our main model as an example, the maximum feed size can reach 650mm, and the production capacity ranges from 150 tons to 400 tons per hour. We can recommend the most suitable portable crawler-mounted jaw crusher model based on your material characteristics and production requirements.

Q3: Is the equipment prone to clogging with very wet or sticky materials?

Yes, this is a common challenge for jaw crushers. We have optimized the feeding system and crushing chamber design, and offer an optional pre-screening feeder to screen out fine powder and wet and sticky parts before the material enters the crushing chamber, effectively reducing the risk of clogging and ensuring continuous and stable operation under complex material conditions.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!