Crawler Mobile Jaw Crusher

On-Site Crushing: The Key to Mining Production Efficiency and Cost Control

In traditional mining operations, raw materials are extracted and then transported over long distances to a fixed crushing and processing plant. This process not only incurs high fuel and transportation costs but also involves dust and noise pollution, as well as potential safety risks. With the increasing demands for cost reduction, efficiency improvement, and green mining practices, the on-site crushing model—"moving the crushing plant to the source of the material"—has become a clear trend in the industry. The core equipment for realizing this concept is the crawler-mounted mobile jaw crusher.

Overview of Crawler-Mounted Mobile Jaw Crushers: Your "Walking Primary Crushing Workshop"

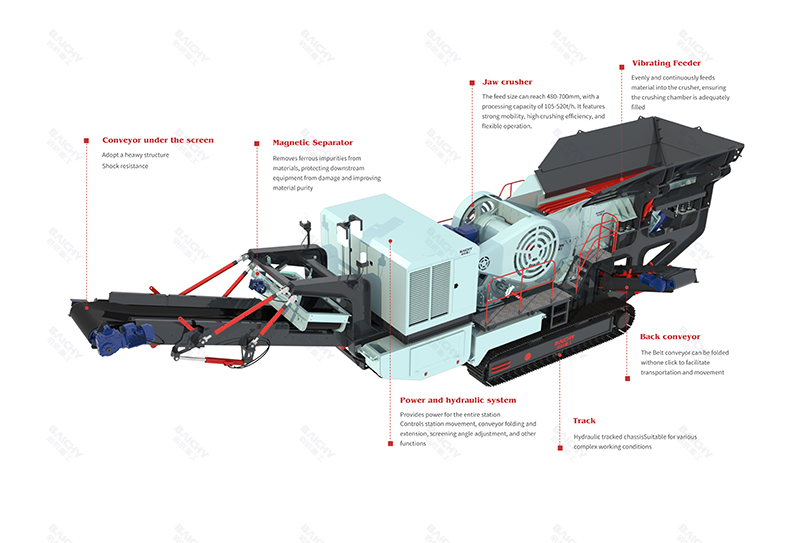

A crawler-mounted mobile jaw crusher, as the name suggests, integrates a high-performance jaw crusher, feeder, conveyor, and power system onto a robust crawler chassis. Without the need for external towing equipment, it can move freely in complex and rugged operating environments such as mines, quarries, and construction waste recycling sites, using its self-contained crawler drive system. This equipment is essentially a complete and independent mobile primary crushing workstation, capable of following the mining face and crushing the blasted or excavated raw ore immediately, processing large materials into a size that can be directly handled by subsequent equipment.

Why Choose a Crawler-Mounted Mobile Jaw Crusher? Four Core Advantages Explained

1. Unparalleled Mobility and Site Adaptability

The crawler track system has low ground pressure and excellent passability on challenging terrain, easily handling muddy, soft, and uneven mining surfaces. It can drive directly to the extraction point, even climbing slopes, completely eliminating the "transportation bottleneck" caused by distance limitations of fixed crushing plants, making it especially suitable for mines with dispersed working faces and deep tunnels.

2. Significant Operating Cost Savings

By eliminating the extensive truck transportation of raw materials between the extraction point and the fixed crushing plant, it directly saves on fuel consumption, fleet maintenance, and labor costs. According to feedback from multiple customer cases, the overall material handling costs can be reduced by as much as 20%-40% after adopting the on-site crushing solution.

3. Rapid Deployment and High Flexibility

Once the equipment arrives on site, it typically only requires simple site preparation and can be put into production within hours. For short-term projects or multi-site rotation operations, its rapid relocation capability is unmatched by fixed production lines. This flexibility significantly improves asset utilization and return on investment.

4. Outstanding Environmental and Safety Benefits

It significantly reduces truck traffic in the mining area, thereby directly reducing exhaust emissions, road dust, and the risk of traffic accidents. At the same time, the equipment can also integrate advanced dust suppression systems and noise reduction devices to achieve a cleaner and safer production environment, helping mines achieve sustainable development goals.

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Successful Application Case: A Leap from Theory to Practice

We provided a high-capacity crawler-mounted mobile jaw crusher to a large gold mine in Australia. The mine faced multiple dispersed ore bodies and challenging road conditions. Traditional transportation solutions were costly. After deploying our equipment, we achieved a "crusher following the ore body" model, reducing the number of transport trucks required by 60%, saving over US$1.5 million in annual operating costs, and recovering the project investment in less than a year.

Equipment Selection Recommendations: How to Match Your Needs?

Choosing the right crawler-mounted mobile jaw crusher requires considering the following factors:

Feed size and hardness: Determines the required jaw crusher model and power.

Expected capacity: Matches the equipment's processing capacity.

Final product size: Adjusts the discharge opening range to meet the feed requirements of the next stage.

On-site working conditions: Such as altitude, climate, material viscosity, and other special conditions.

We recommend that you communicate in detail with our technical engineers. We will provide you with customized mobile crushing solutions to ensure maximum equipment efficiency.

Frequently Asked Questions (FAQ)

Q1: Can the crawler-mounted mobile jaw crusher complete the entire crushing process independently?

It usually serves as the core unit for primary crushing. It mainly processes large chunks of raw ore, producing uniform intermediate-sized material. If multiple specifications of final aggregate are required, it usually needs to be combined with a crawler-mounted mobile cone crusher or impact crusher to form a multi-stage mobile crushing and screening production line.

Q2: What are the fuel consumption and maintenance costs of the equipment?

Modern, advanced crawler-mounted mobile jaw crushers typically utilize high-efficiency diesel engines or can be switched to external power sources. Due to the elimination of extensive truck transportation, their overall fuel efficiency is significantly improved. In terms of maintenance, they feature centralized lubrication and intelligent monitoring systems, making daily maintenance convenient, and key components are easily accessible, aiming to reduce long-term operating costs.

Q3: Is it suitable for processing construction and demolition waste?

Absolutely. It is a powerful tool for the resource utilization of construction waste. The powerful jaw crusher can easily crush concrete blocks, masonry, etc., and can separate rebar through a magnetic separator. Its mobility allows for direct operation at demolition sites, enabling the transformation of waste into valuable resources, making it an ideal choice for urban mining development.

In today's pursuit of ultimate efficiency and sustainability, crawler-mounted mobile jaw crushers are no longer an option, but rather a standard configuration for modern, intelligent mining operations. They represent a fundamental shift in thinking from "transporting materials to the machine" to "the machine going to the materials," and are a powerful weapon for mining companies to enhance their core competitiveness and achieve green transformation.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!