In the field of non-metallic mineral powder processing, many business owners and engineers are still familiar with the classic Raymond mill. However, with the continuous improvement of global market requirements for capacity, energy consumption, and environmental protection, the limitations of the traditional Raymond mill are becoming increasingly apparent.

So, what are the essential differences between the traditional Raymond mill and its technological successor, the European trapezoidal grinding mill (MTW series)? What tangible benefits does the upgrade bring?

This article will provide a thorough comparative analysis to help you make the wisest investment decision.

I. Core Differences Comparison

We will visually demonstrate how the European trapezoidal grinding mill comprehensively surpasses the traditional Raymond mill from five key dimensions: transmission system, air duct design, grinding efficiency, environmental performance, and level of intelligence.

Comparison Dimensions: Traditional Raymond Mill vs. MTW European Trapezoidal Grinding Mill

Advantages Explained:

| Comparison Dimensions | Traditional Raymond Mill | MTW European Trapezoidal Mill |

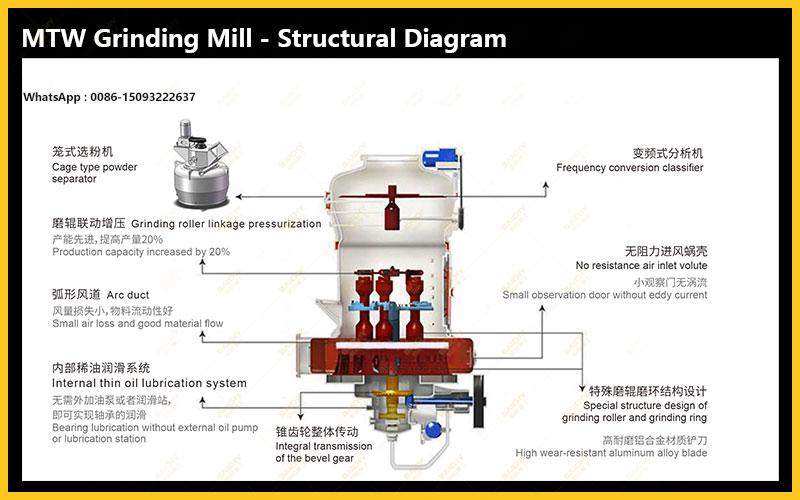

| 1. Transmission System | Uses a reducer + open gear transmission, resulting in a long transmission chain, low efficiency (typically <90%), prone to oil leaks, rapid wear, and frequent maintenance. | Innovative vertical bevel gear integral transmission, with a short transmission path and efficiency exceeding 98%; thin oil lubrication, lifetime maintenance-free, and no risk of oil leaks. |

| 2. Air Duct Design | Straight-plate air ducts have high air resistance, are prone to material accumulation, leading to unstable output and high energy consumption. | Internal curved air ducts have low air resistance, are less prone to material accumulation, and ensure smooth air intake; the air duct plates have replaceable blades on all four sides, greatly extending wear life. |

| 3. Grinding Efficiency and Adaptability | The grinding roller device has grinding dead angles, making it difficult to "bite" flaky or slightly high-moisture materials, easily causing blockages and limiting efficiency. | The trapezoidal grinding roller and grinding ring design increases the contact area, eliminates dead angles, and improves grinding efficiency; it also offers greater adaptability to material moisture content. |

| 4. Environmental Performance | Typically, simple dust collectors are used, or additional dust collection systems are required, resulting in poor dust emission control and a poor workshop environment. | Standard configuration includes a high-efficiency pulse bag filter, with a dust removal efficiency of over 99.9%, and dust emissions far below international environmental standards, achieving green and clean production. |

| 5. Automation Level | Most operations are manual, highly dependent on operator experience, labor-intensive, and difficult to guarantee consistent product quality. | A PLC centralized control system can be used to achieve remote control, automatic feeding, and fault alarms, facilitating management and ensuring stable product quality. |

II. Technical Parameters of the MTW European Trapezoidal Grinding Mill

| Model | Roller Size (mm) | Grind Ring Size DxH(mm) | Main Roller Speed (r/min) | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| MTW110 | 360×210 | 1100×210 | 120 | 30 | 0.038-1.6 | 4-12 | 55 | 8910×6950×9010 |

| MTW138 | 460×260 | 1380×260 | 96 | 35 | 0.038-1.6 | 8-20 | 110 | 9860×8340×10227 |

| MTW175 | 520×300 | 1750×300 | 75 | 40 | 0.038-1.6 | 20-35 | 200 | 13500×11500×9500 |

| MTW215 | 640×340 | 2150×340 | 65 | 50 | 0.038-1.6 | 30-50 | 280 | 13922×9810×13226 |

III. Why Choose Our MTW European Trapezoidal Grinding Mill?

When you choose our MTW European-style trapezoidal grinding mill, you gain more than just a high-performance piece of equipment; you receive a complete solution guaranteeing success:

• Professional Manufacturer, In-Stock Supply: As a professional MTW grinding mill manufacturer, we have a large production base and a comprehensive inventory system, enabling us to provide in-stock supply services and shorten your project delivery cycle.

• One-Stop Solution: From free material testing and selection advice in the early stages, to equipment installation, commissioning, and operation training in the middle stages, and to lifetime after-sales service and spare parts supply, we provide comprehensive support.

• Focused on Large-Scale Projects: This series of equipment is designed for large-scale production, especially adept at processing materials such as limestone, slag, and calcite, making it an ideal choice for modern large-scale powder processing projects.

Upgrading is Not Just About Replacing Equipment, It's About Enhancing Competitiveness

In summary, the European-style trapezoidal grinding mill is not simply a model update, but a comprehensive technological innovation in transmission, grinding, air classification, environmental protection, and intelligent systems. Choosing an MTW grinding mill means choosing lower cost per ton of powder, higher product competitiveness, easier environmental compliance, and more modern factory management. Investing in an advanced European-style trapezoidal grinding mill is a strategic step towards eliminating outdated production capacity and seizing market opportunities.

Inquire now for a customized solution and quote!

If you are troubled by the inefficiency of your existing production line or are planning a new powder project, please contact our technical experts immediately. We will provide you with the most cost-effective and efficient solutions and detailed equipment information based on your specific needs.

Further reading:

How To Choose A Suitable Industrial Grinding Mill?

Which Is Better Cement Vertical Roller Mill Or Ball Mill?

What Are the Differences between Dry and Wet Type Ball Mill?