In numerous industrial sectors such as ore grinding, building materials, metallurgy, and chemicals, the demand for powders with a medium fineness range of 80 to 400 mesh (approximately 180-38 microns) is the most widespread. Whether it's cement raw materials, power plant desulfurization limestone powder, or the deep processing of non-metallic minerals, manufacturers are seeking equipment that achieves the optimal balance between energy consumption, output, and fineness. After long-term market validation, the European-style grinding mill has become the absolute mainstay and preferred solution in this niche market. What are the underlying reasons for this?

I. High Efficiency and Low Energy Consumption Brought by Vertical Structure

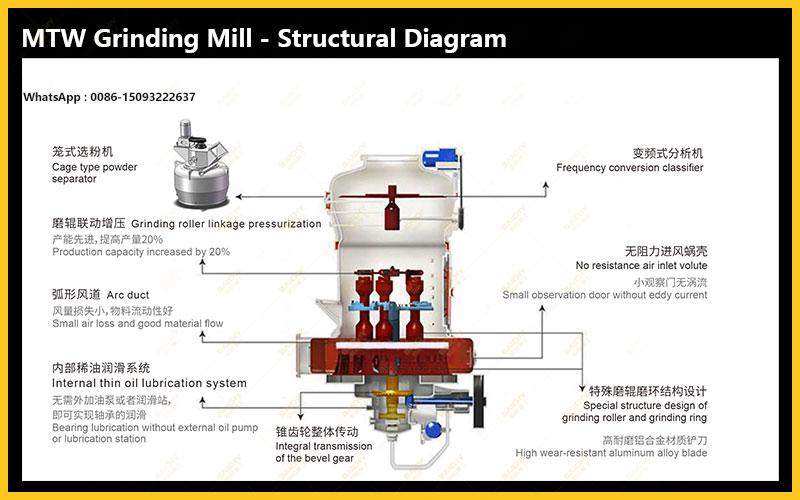

Compared to traditional Raymond mills, the European-style grinding milladopts a mature vertical structure design. During operation, the central shaft drives the grinding rollers and grinding ring to crush the material. This structure naturally has the following advantages:

• Utilizing gravity to improve efficiency: The material falls naturally, is scooped up and crushed by the grinding rollers, reducing the energy loss required to lift the material.

• Significantly Reduced Energy Consumption: At the same power output, the output is 20%-30% higher than traditional Raymond mills, with lower energy consumption per unit product, resulting in substantial long-term electricity savings.

II. Curved, Reversible Grinding Rollers Ensure Fineness and Uniformity

This is the "soul" of the European-style grinding mill. Its grinding rollers are not traditional cylindrical but feature a curved design, and can be flipped for reuse after wear, significantly extending their lifespan.

• Larger Compaction Area, Superior Finished Product: The curved grinding rollers have a larger and more uniform contact area with the grinding ring, resulting in better material compaction and extremely high particle size uniformity, avoiding over- or under-grinding.

• Easily Handles 80-400 Mesh: This design is particularly suitable for the large-scale production of medium to fine powders, consistently outputting high-quality finished products within this fineness range.

III. Convenient Finished Product Fineness Adjustment and Extremely High Stability:

Users can easily control the fineness of the finished product by adjusting the speed of the analyzer above the main unit without stopping the machine.

• Flexible Adjustment: The faster the analyzer rotates, the stricter the powder sorting requirements, allowing only the finer powders to pass through, thus easily achieving stepless adjustment from 80 mesh to 400 mesh.

• Stable Operation: The entire system operates smoothly with minimal vibration, ensuring continuous production and consistent finished product quality, making it ideal for automated production lines.

IV. Extended Equipment Lifespan, Meeting Stringent Standards

• Long Wear-Resistant Part Lifespan: Core wear-resistant parts such as grinding rollers and grinding rings are made of high-quality alloy steel and treated with special processes, resulting in excellent wear resistance and significantly reducing maintenance costs and downtime.

• Environmentally Friendly Closed-Loop Production: The equipment has excellent overall sealing performance and can be equipped with a pulse dust collector, resulting in dust emission concentrations far below national environmental standards, creating a clean and environmentally friendly production environment.

In summary, the European-style grinding mill, with its high efficiency and low consumption due to its vertical structure, fine grinding with curved grinding rollers, convenient and flexible fineness adjustment, excellent reliability, and good environmental performance, has successfully achieved a perfect balance of efficiency, cost, and quality in the core powder processing field of 80-400 mesh. It is not a device that pursues extreme fineness, but rather provides users with the most economical, stable, and reliable solution within the widest range of applicable fineness. This is the fundamental reason why it has become the market's first choice.