The Unique Challenges of Construction in the Malpes Archipelago

The Malpes, a resort paradise composed of hundreds of coral islands, faces unique challenges in its infrastructure construction and renovation projects. The islands are scattered, land resources are scarce, environmental requirements are extremely stringent, and the cost of building large, fixed production lines is prohibitively high. For local contractors, handling construction demolition waste, coral rock, or producing small quantities of aggregate requires a flexible, efficient, and environmentally friendly solution. This is the core reason why we recommend the combination of a mobile jaw crusher and a mobile impact crusher.

Concrete Crushing Solution - Recommended Mobile Jaw Crusher + Impact Crusher Equipment

One-Stop Mobile Crushing Solution

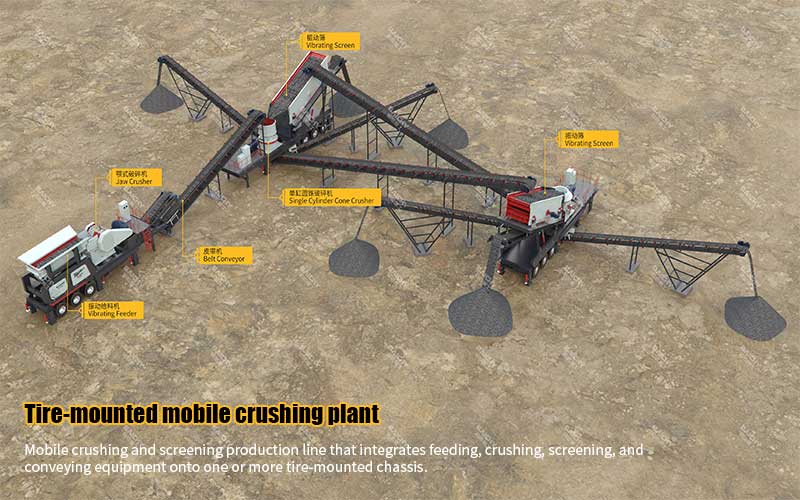

This combination is not simply a stacking of equipment, but an integrated, high-production process designed for small-to-medium scale, multi-site operations. The mobile jaw crusher acts as the primary crushing unit, responsible for the initial crushing of large pieces of concrete and construction waste; it is then connected to a mobile impact crusher, which acts as the secondary crushing unit, further processing the crushed material into high-quality aggregate that can be used directly. Both machines are independently mobile and can be quickly moved between different islands or construction sites using motorized vehicles.

Core Advantages: Why is this combination suitable for the Malpes?

1. Unparalleled Mobility and Flexibility

• Rapid Relocation: The wheeled design allows for towing by standard tractor units, perfectly adapting to the limited road conditions and inter-island boat transportation in the Malpes, enabling a this island today, that island tomorrow operational model.

• Quick Setup: Upon arrival at a new construction site, there is no need for complex foundation pouring; simple site leveling is sufficient to quickly begin work, allowing for production within hours and significantly shortening project preparation time.

2. Significant Economic and Environmental Benefits

• Reduced Transportation Costs: On-site processing of construction waste and concrete debris transforms waste into recycled aggregate, avoiding the double burden of transporting waste off the islands and new aggregate onto the islands.

• Resource Recycling: This process transforms waste into valuable resources, with the resulting recycled aggregate directly usable for backfilling, road bases, or low-grade concrete, aligning with global trends in sustainable development. • Reduced Carbon Footprint: The on-site processing model significantly reduces carbon emissions from long-distance material transportation, protecting the precious natural environment of the Malpes.

3. Compact, Efficient, and Easy to Operate

• Space-Saving: The integrated design makes the entire production line compact, requiring minimal operating space, which is ideal for the limited work areas in the Malpes.

• Simple Operation and Maintenance: Utilizing a mature electrical control system and user-friendly design reduces the reliance on highly skilled technicians. The modular design also makes daily maintenance and upkeep more convenient.

Concrete Crushing Solution - Recommended Mobile Jaw Crusher + Impact Crusher Equipment

Application Cases: Successful Practices in Similar Scenarios

We have provided similar solutions to clients in several island nations and remote areas. For example, in a resort expansion project on a tourist island in Southeast Asia, the client successfully converted approximately 50,000 tons of concrete blocks from demolished buildings into recycled aggregates of different specifications within 3 months using a combination of a mobile jaw crusher and a mobile impact crusher. These aggregates were then used for the construction of new road bases and parking lots. This project not only saved over 40% in material costs but also received recognition from the local environmental protection department for avoiding a large amount of ship transportation. This fully demonstrates the excellent adaptability and economic efficiency of this solution in environmentally sensitive areas.

Equipment Recommendations and Configuration Suggestions

As a manufacturer with 20 years of professional experience, we recommend the following configuration for our Malpian clients:

• Primary Crushing Unit: Medium-sized wheeled mobile jaw crusher, with a feed opening large enough to handle large concrete components such as floor slabs and beams.

• Secondary Crushing Unit: Wheeled mobile impact crusher, with excellent shaping capabilities to produce high-quality aggregates.

• Optional: Mobile vibrating screen for precise aggregate grading; or a light-duty feeder to create a smoother production line.

Frequently Asked Questions (FAQ)

1. How is the power supplied to this mobile equipment?

Our equipment typically uses diesel generator sets (which can be built-in or external), making it completely self-sufficient and independent of potentially unstable power grids on the islands, making it particularly suitable for operation on remote islands with limited infrastructure.

2. What are the corrosion resistance properties of the equipment?

Can it withstand a marine climate? Given the high temperatures, high humidity, and high salinity of the Malpian marine climate, we can provide heavy-duty anti-corrosion coating solutions, special treatment for critical structural components and easily corroded parts, and offer stainless steel options to ensure the durability and service life of the equipment in harsh environments.

3. How are after-sales service and technical support guaranteed?

We provide support through a local agent + headquarters expert model. Before equipment delivery, we will provide comprehensive training for the customer's operation and maintenance personnel. We are committed to providing remote online technical support, and through regional service centers and parts warehouses, we ensure that critical parts can be delivered quickly, maximizing the continuity of your construction operations.

For a country like the Malpes with its unique geographical environment and stringent environmental requirements, flexibility, economy, and environmental protection must be prioritized when choosing crushing and screening equipment. The combination of our recommended wheeled mobile jaw crusher and mobile impact crusher is a powerful tool specifically designed for these needs. It is not only a set of production equipment, but also a mobile resource recycling plant that can help you reduce costs, improve efficiency, and practice environmental protection.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)