Granite Sand Making Solution | 10tph Double Roll Crusher for <3mm Output | Ethiopia

Providing Efficient Solutions for Granite Sand Production Projects in Ethiopia

We understand that our clients in Ethiopia are actively seeking roller crushers for granite sand production, with the core requirements being an output particle size of less than 3mm and a production capacity of approximately 10 tons per hour (tph). This is a very typical and clearly defined requirement for a small to medium-sized artificial sand production project. As a manufacturer of mining crushing equipment with 20 years of professional experience, we know that choosing the right equipment is the cornerstone of project success and profitability. This article will analyze this need in detail and explain why our roller crusher is your ideal choice.

| Key Words | Granite Sand Making Solution |

|---|---|

| Product Model | Double Roller Crusher |

| Feed Size | ≤50mm |

| Motor Power | 5.5-45kw |

| Capacity | 2-150t/h |

| Core Advantages | The two rollers rotate in opposite directions, performing "controlled squeezing and grinding." |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why a Roller Crusher?

Granite is hard and highly wear-resistant, making it a high-quality raw material for construction aggregates. Crushing it into fine sand of less than 3mm presents a dual challenge to the crushing principle and wear resistance of the equipment.

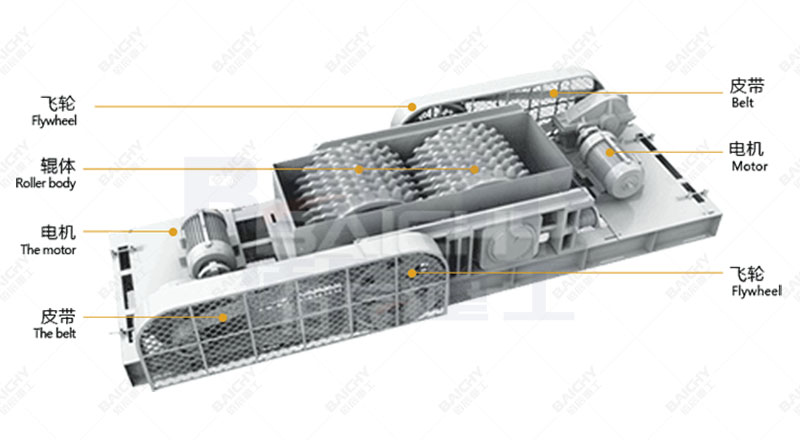

Structure diagram of a double-roll crusher

• Output Requirements: An output of less than 3mm means that a device capable of producing a large amount of inter-particle crushing and good particle shape control is required. Excessive impact crushing may produce too much fine powder, while compression crushing can better control the particle size distribution.

• Production Capacity Requirements: 10 tph is a small to medium-sized capacity, requiring flexible equipment configuration, economical energy consumption, and a small footprint, suitable for local investment scale and site conditions.

Based on the above analysis, while the traditional jaw crusher + cone crusher combination can process granite, for this fineness and small capacity requirement, the process may be too long and the investment too high. Hammer crushers, on the other hand, wear out quickly and the output particle shape is difficult to guarantee. This is where the advantages of a roller crusher (also known as a double-roll crusher) become apparent.

High-Efficiency, Wear-Resistant Roller Crusher for Granite

Our series of roller crushers, specifically developed for fine crushing and sand production of hard rock, perfectly meets the needs of our Ethiopian clients.

Core Advantages of the Equipment

1. Precise Particle Size Control: The gap between the two rollers can be adjusted precisely and conveniently, which is key to ensuring a stable output of less than 3mm. By adjusting the gap, you can easily obtain the required sand specifications with a very high yield.

2. Excellent Particle Shape and Low Fines Content: Utilizing a crushing principle primarily based on extrusion and grinding, the produced sand has a predominantly cubical particle shape and a reasonable gradation. The fines content is controllable, far superior to the flaky material produced by hammer crushers, significantly improving concrete strength and mortar quality.

3. Exceptional Wear Resistance for Granite: The roller shells are made of our specially formulated high-chromium alloy cast iron or composite wear-resistant materials, treated with a special heat treatment process. Their wear resistance is more than three times that of ordinary manganese steel, specifically designed to handle the high wear characteristics of granite, significantly reducing your long-term operating costs.

4. Compact Structure and High Cost-Effectiveness: The equipment has a simple and compact structure, requiring minimal foundation construction investment and offering easy installation and maintenance. For a production capacity target of 10 tph, the motor power configuration is reasonable, resulting in low energy consumption, making the overall investment and operating costs highly competitive in the market.

5. Overload Protection and Stable Operation: The equipment is equipped with a spring or hydraulic adjustment system. When uncrushable materials enter, the rollers can automatically retract to discharge foreign objects, preventing equipment damage and ensuring the continuous and stable operation of the production line.

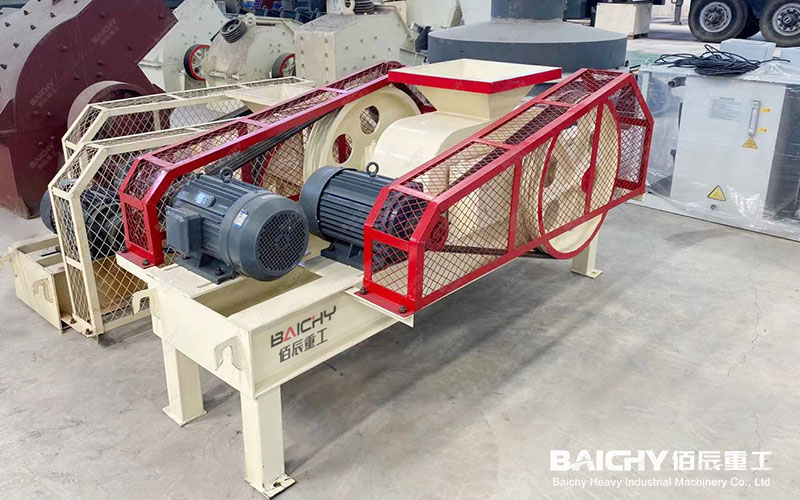

Double-roll crusher customer site

Similar Scenarios, Proven Results

We have multiple successful applications in East Africa. For example, at a quarry in Tanzania, the customer used our 2PG800×600 model roller crusher to process local granite. With a feed size of ≤30mm, by adjusting the roller gap, it consistently produced high-quality manufactured sand of 0-3mm, with a stable production capacity of 10-12 tph, fully meeting local construction sand standards. The customer highly praised the equipment's low failure rate and long service life of wear parts.

Equipment Selection Recommendation

For the specific requirements of granite, output <3mm, production capacity 10 tph, we highly recommend the reinforced 2PG750×500 or 2PG800×600 model double-roll crushers. These models have been specifically optimized in terms of power configuration, roller surface wear-resistant design, and adjustment accuracy, making them an efficient and reliable choice for the success of your project.

Frequently Asked Questions (FAQ)

Q1: When processing hard stones like granite, will the roller wear out very quickly, resulting in high replacement costs?

A1: This is our core focus. As mentioned in the advantages, we provide wear-resistant roller shells specifically designed for granite. Using special alloys and processes, their service life is several times longer than conventional roller shells. Even when replacement is needed, our roller shells feature a modular design for easy replacement, and we guarantee a long-term supply of competitively priced original parts to ensure the lowest overall operating cost for you.

Q2: How do you ensure the output material is consistently less than 3mm?

A2: Firstly, the mechanical structure of the equipment ensures the precision of roller gap adjustment and the reliability of locking. Secondly, we recommend that you use a vibrating screen or a pre-crusher (such as a jaw crusher) to control the granite raw material to below 30-40mm before feeding. This ensures effective engagement and compression between the two rollers, thus stably and efficiently producing sand particles smaller than 3mm. Our engineers will provide detailed operating parameter guidance.

Q3: Besides this roller crusher, what other main equipment is needed for the entire production line? Can you provide support?

A3: A simple sand production line typically includes: feeder (for uniform feeding) → small jaw crusher (for coarse crushing) → our roller crusher (for fine crushing and sand making) → vibrating screen (for screening and grading). We can provide complete solutions, from single machines to complete production line layouts, based on your specific raw materials and final product requirements, and assist with installation guidance and commissioning.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.