Rock & Aggregate Crushers

In mining, construction aggregate production, and various large-scale engineering projects, rock and aggregate crushers are undoubtedly the "heart" of the entire production line. A high-efficiency, reliable crusher plays a decisive role in the success of a customer's project. This article will delve into this core equipment to help you fully understand its technology and applications.

Why are crushers so crucial?

The core task of a rock and aggregate crusher is to crush large pieces of mined raw material into specific particle sizes that meet the requirements of subsequent processes or final products through mechanical force, including compression, impact, and grinding. This is not merely a simple process of "reducing size," but a key factor determining production efficiency, finished product quality, and operating costs.

Overview of Crushing Processes

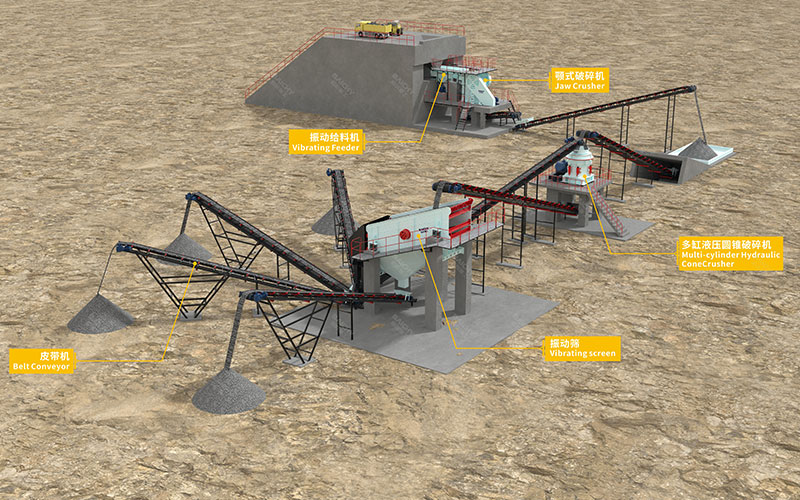

A typical crushing process consists of three stages: coarse crushing, medium crushing, and fine crushing. Coarse crushing typically handles raw materials with a diameter exceeding 1 meter, crushing them to approximately 250-300 mm; medium crushing further processes them to 60-80 mm; and fine crushing produces finished aggregate smaller than 30 mm. Different types of crushers are required for different stages and material characteristics (such as hardness, abrasiveness, and moisture content).

Layout diagram of aggregate crushing production line

Core Advantages: The Value Brought by Advanced Crusher

Choosing technologically mature crushing equipment can bring immediate benefits to production.

Superior Production Efficiency and Output Quality

Modern high-efficiency rock and aggregate crushers utilize optimized crushing chamber designs and higher rotational speeds, significantly increasing throughput per unit time. Simultaneously, advanced laminar crushing principles produce more cubic particles, reducing needle-like and flaky content, significantly improving the gradation and quality of aggregate products, resulting in better performance in high-standard concrete and asphalt mixtures.

Significant Operating Economy and Reliability

Based on 20 years of design experience, wear-resistant materials and highly reliable structures have been thoroughly validated. Key components (such as hammers and jaw walls) have long service lives, reducing replacement frequency and downtime. Modular design also makes maintenance more convenient, greatly reducing the production cost per ton of aggregate in the long run.

Flexible Configuration and Intelligent Control

Whether in fixed production lines or mobile crushing plants, today's crushers can be flexibly integrated. With an intelligent control system, it can monitor load, adjust parameters, and provide early warnings of faults in real time, achieving automated and visualized production management and reducing reliance on manpower.

Success Stories

We have numerous successful applications globally. For example, a large granite quarry project in Southeast Asia had insufficient production capacity and poor particle shape of the finished product from its original production line. We configured a new type of hydraulic cone crusher for medium and fine crushing, ultimately increasing aggregate output by 35%, with the proportion of cubic finished products exceeding 90%, fully meeting the needs of the local high-end construction market, and significantly shortening the customer's return on investment cycle.

Equipment Selection Recommendations

• First choice for coarse crushing: Jaw crusher. Known for its robust structure and strong adaptability, it is the "main force" for processing large rocks.

• Preferred for medium and fine crushing: Cone crusher or impact crusher. For high-hardness rocks, the multi-cylinder hydraulic cone crusher is the most energy-efficient choice; for medium and low-hardness materials, the impact crusher has advantages in particle shape adjustment and cost.

• Mobile solutions: Wheeled or tracked mobile crushing plants. Suitable for projects with multiple work sites and limited space, enabling "on-the-go crushing" with unparalleled flexibility.

Frequently Asked Questions (FAQ)

Q1: How do I choose the right crusher type based on the hardness of my rock?

A1: Rock hardness is usually measured using Mohs hardness or compressive strength. For high-hardness rocks (such as granite and basalt), a cone crusher based on the principle of layered crushing is recommended. For medium- to low-hardness rocks (such as limestone and dolomite), an impact crusher based on the principle of impact crushing can be used to obtain better particle shape and lower energy consumption.

Q2: How should I choose between a mobile crushing plant and a stationary production line?

A2: This mainly depends on the project cycle and the terrain. Stationary production lines have lower investment, higher output, and lower operating costs, making them suitable for long-term, large-scale mines with concentrated raw materials. Mobile crushing plants have higher investment but are flexible to relocate and quick to install, making them ideal for short-term, dispersed engineering contracts or urban construction waste treatment projects.

Q3: How can I effectively control dust pollution during the crushing process?

A3: Modern crusher designs have integrated multiple environmental protection measures. We recommend using enclosed conveying and crushing units, and installing high-efficiency spray dust suppression systems or bag filters at key dust-generating points (such as the feed inlet and discharge outlet) to effectively control dust within national standards and achieve green production.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!