Types of Crushers: Cone, Jaw, Impact, Gyratory and more

In industries such as mining, building materials, and road construction, crushing is the first and most crucial step in material processing. Choosing efficient crushing equipment is key to ensuring production line capacity, finished product quality, and economic benefits. As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we understand that understanding the principles and characteristics of each crusher is the first step in making the right decision.

Crushers are not "one-size-fits-all" devices. Different types of crushers have different working principles, applicable materials, and output particle size ranges. They can be mainly pided into coarse crushing, medium crushing, and fine crushing equipment.

The "Hercules" of the Coarse Crushing Stage: Jaw Crusher and Gyratory Crusher

Coarse crushing is the first step in processing large pieces of raw rock, requiring equipment with strong "biting force" and throughput.

Jaw Crusher - A Robust and Reliable Trailblazer

Jaw Crusher - A Robust and Reliable Trailblazer

Overview and Analysis: The jaw crusher has a simple structure and reliable operation, making it the most widely used coarse crushing equipment. Its working principle is to crush materials through the periodic squeezing motion between the moving jaw and the fixed jaw.

Core Advantages:

• Robust Structure: Easy equipment maintenance and low operating costs.

• High Adaptability: Can handle ores and rocks of various hardnesses, with compressive strength up to 320MPa.

• Large Feed Inlet: Easily accepts large pieces of material, making it the standard for primary crushing in mines.

Gyratory Crusher - A High-Yield, Continuous Crushing Giant

Gyratory Crusher - A High-Yield, Continuous Crushing Giant

Overview and Analysis: The gyratory crusher is also used for coarse crushing. Its crushing cone rotates within the machine body, continuously compressing and crushing the material.

Core Advantages:

• Extremely High Processing Capacity: Low unit power consumption, particularly suitable for large mines and large-scale production lines.

• Continuous Feeding and Crushing: Production efficiency far exceeds that of intermittent jaw crushers, with smoother operation.

• Uniform Product Particle Size: The crushing chamber design makes it easier to control product particle size.

hydraulic cone crusher for iron ore

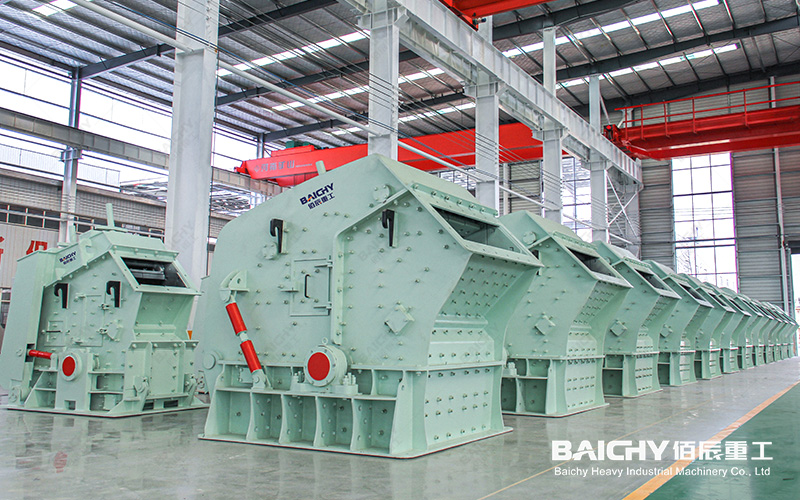

PF Impact Crusher

Versatile Performers in Medium and Fine Crushing: Cone Crusher and Impact Crusher

After coarse crushing, materials need further processing into smaller particle sizes to meet the requirements of the next stage of grinding or direct use.

Cone Crusher - Energy-Saving Expert for Hard Rock Crushing

Overview and Analysis: The cone crusher utilizes the gyratory motion of a moving cone within a fixed cone cavity to achieve layered crushing of materials. It is particularly suitable for processing high-hardness materials such as granite and basalt.

Core Advantages:

• Layered Crushing Principle: Particles are crushed by mutual compression within the cavity, resulting in good particle shape, high production efficiency, and low wear on wear parts.

• High Degree of Automation: Modern hydraulic cone crushers are equipped with automatic cavity clearing, overload protection, and hydraulically adjustable discharge port functions, achieving a high level of automation.

• Stable and Reliable Operation: Suitable for medium, fine, and ultrafine crushing operations, it is the first choice for high-quality aggregate production.

Impact Crusher (Sand Making Machine) - The Master of Particle Shape Shaping

Overview and Analysis: The impact crusher utilizes a high-speed rotating rotor to throw material against the impact plate, achieving crushing through the principle of "stone against stone" or "stone against iron." It is the mainstay of manufactured sand production and aggregate shaping.

Core Advantages:

• Excellent Finished Particle Shape: The product is mostly cubic with low needle-like and flaky content, suitable for high-grade highways, construction, and commercial concrete aggregates.

• Combines Crushing and Shaping Functions: Multi-functional, achieving a breakthrough in "stone-to-sand" transformation.

• Flexible Adjustment: By adjusting the rotor speed, impact plate gap, etc., the product particle size can be easily changed.

Success Story Sharing

Our three-stage crushing and screening system for a large granite quarry in Southeast Asia, consisting of a jaw crusher (coarse crushing), a cone crusher (medium and fine crushing), and an impact crusher (sand making and shaping), increased the final aggregate product qualification rate to over 95%, with needle-like and flaky content below 8%, fully meeting the material standards for key local projects. The equipment operated stably, and maintenance costs were lower than the client's expectations.

Equipment Selection Recommendations

• For high-output coarse crushing: Gyratory crushers are the first choice for large projects; jaw crushers are optional for small and medium-sized projects.

• For crushing high-hardness ores: Cone crushers are essential for the medium and fine crushing stages, especially multi-cylinder hydraulic models.

• For producing high-quality manufactured sand/shaping: Impact crushers (sand making machines) are the best choice.

• For mobile crushing needs: Based on the above combinations, a mobile jaw crusher + mobile cone crusher or mobile impact crusher configuration can be selected.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a jaw crusher and a cone crusher?

A1: The main difference lies in their working principles and application stages. Jaw crushers use intermittent compression and are mainly used for primary coarse crushing; cone crushers use continuous layered crushing and are mainly used for secondary medium and fine crushing. Cone crushers typically produce more uniform particle shape, but their purchase and maintenance costs are also higher.

Q2: Can impact crushers crush high-hardness ores?

A2: Yes, but it's not economical. The wear-resistant parts of impact crushers (such as hammers and impact plates) wear very quickly when crushing high-hardness materials, leading to a sharp increase in operating costs. For high-hardness materials, cone crushers, which are more wear-resistant and have a more suitable operating principle, are recommended for the medium and fine crushing stages.

Q3: Besides material hardness, what other factors should be considered when selecting equipment?

A3: This is a comprehensive decision-making process. You also need to focus on the following:

1) Feed particle size and required discharge particle size;

2) Expected production capacity (tons/hour);

3) Particle shape requirements of the final product (e.g., for commercial concrete or asphalt);

4) Investment and operating cost budget; 5) Site layout of the production line and whether it needs to be moved.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!