An aggregate crushing production line is an industrialized production system that combines a series of mechanical equipment according to a specific technological process. This system processes large ores (such as limestone, granite, basalt, etc.) through multi-stage crushing, screening, and washing processes to produce sand and gravel aggregates of various particle sizes required for construction projects.

Core Objective: To efficiently, economically, and environmentally produce high-quality aggregates that meet international standards (such as GB/T 14685-2022). Products include crushed stone and manufactured sand of various particle sizes.

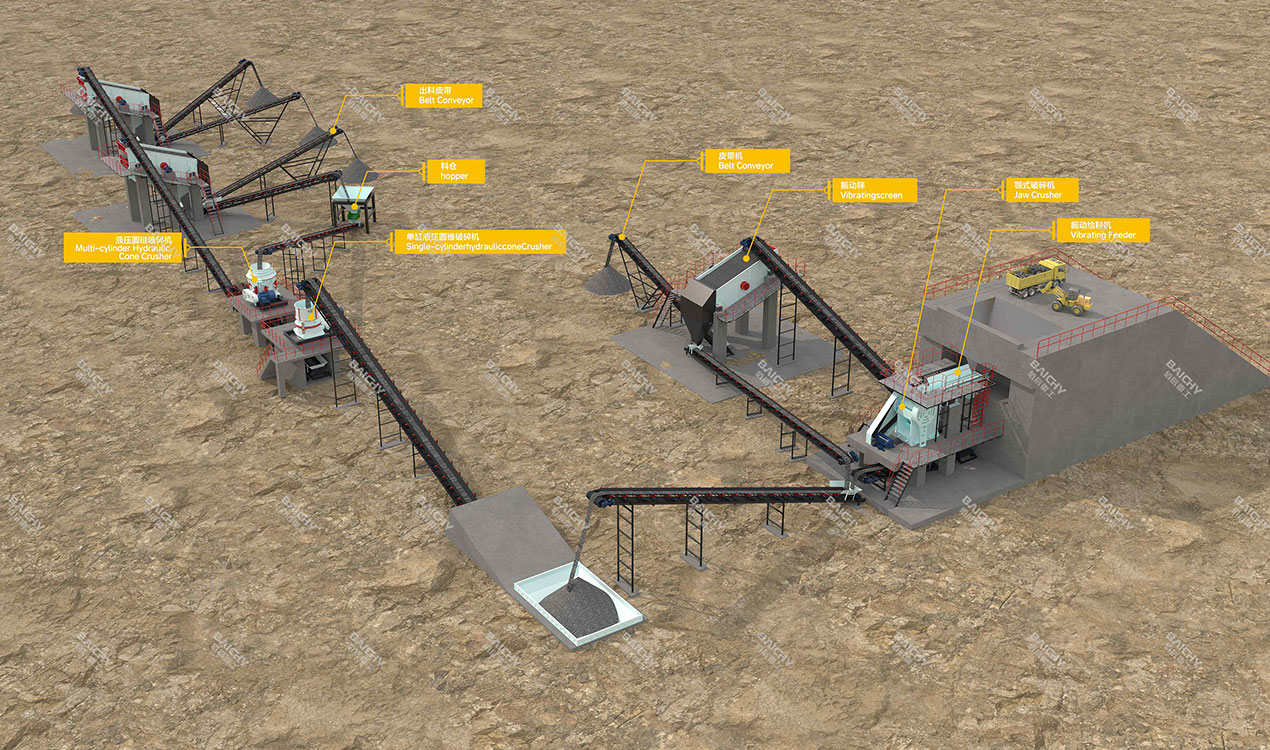

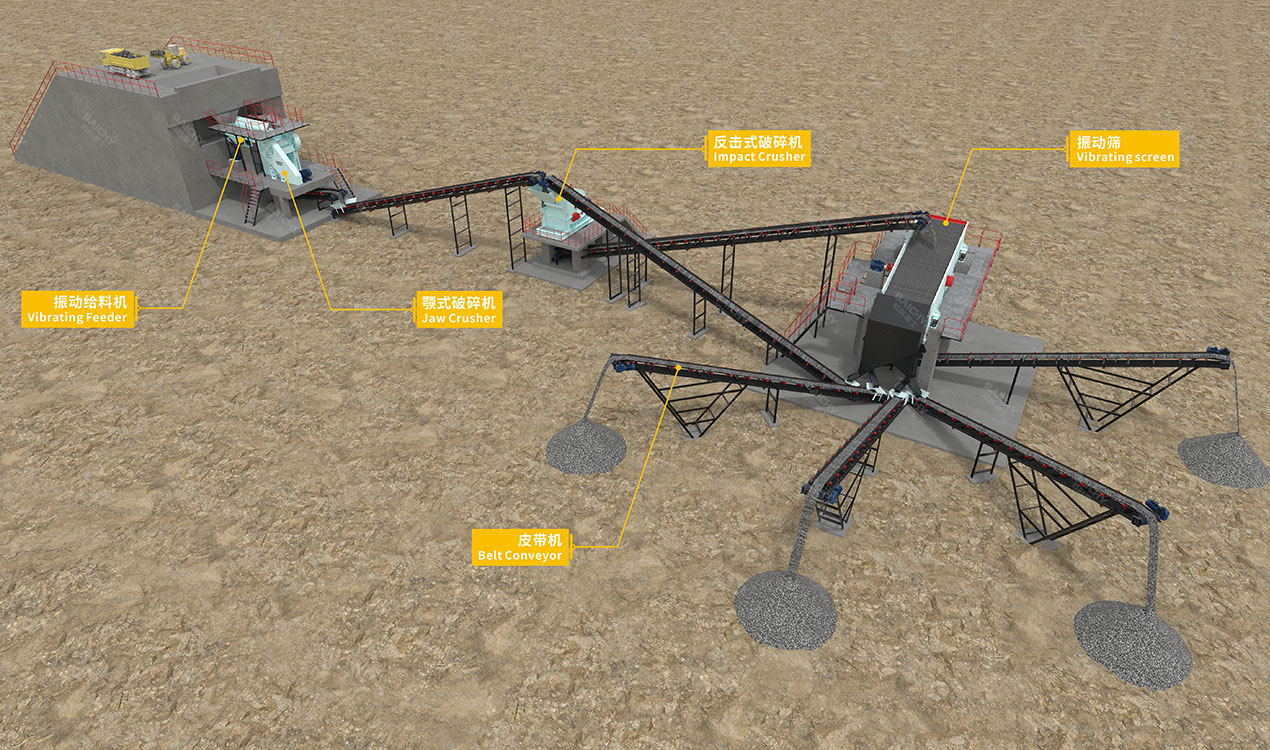

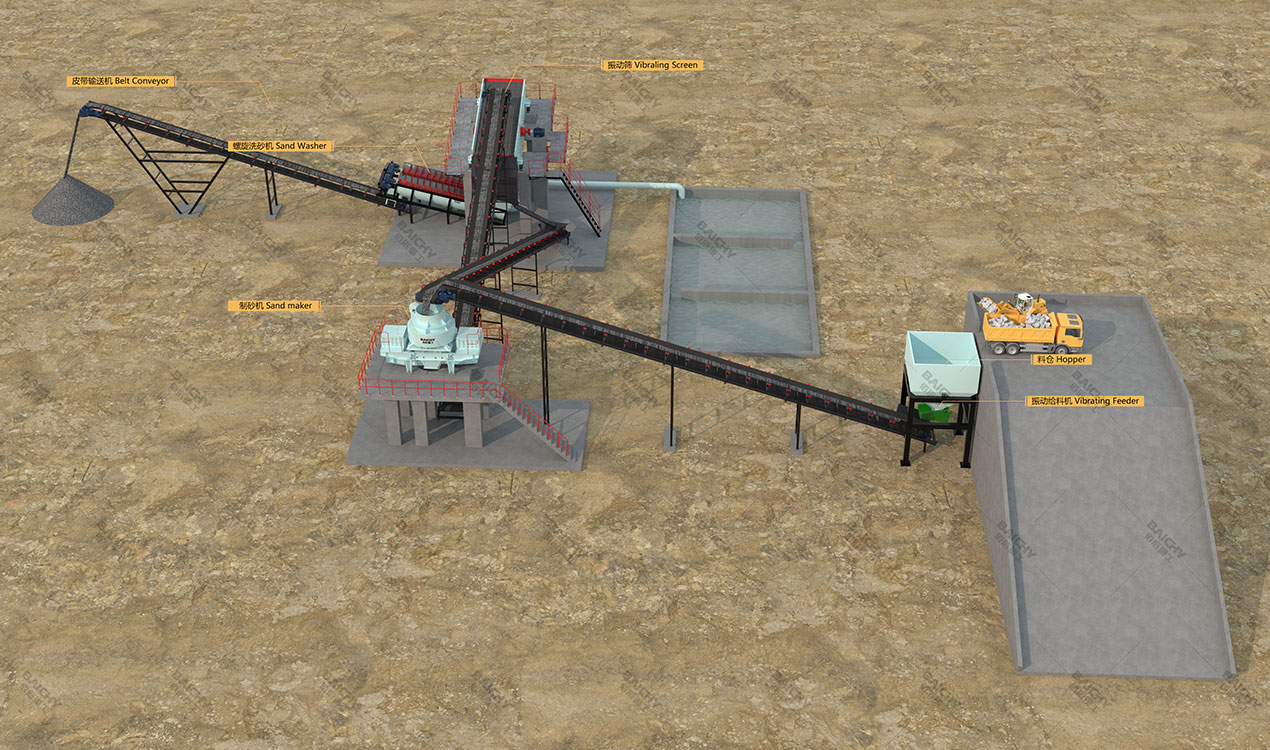

The aggregate crushing production line uses "multi-stage crushing + multi-stage screening" as its core process, typically employing a "two-stage closed-circuit" or "three-stage closed-circuit" process. Raw materials are fed into a jaw crusher for coarse crushing via a vibrating feeder, followed by medium crushing via an impact crusher or cone crusher. Finally, the crushed mixture is graded by a multi-layer vibrating screen. Large particles on the upper screen are returned or sent to the next crushing process (such as being fed into a sand making machine for fine crushing and shaping), while qualified aggregates are transported by belt conveyors to different finished product stockpiles for storage and transportation. The modern production line is also equipped with a complete set of environmentally friendly intelligent auxiliary systems, including bag filters, cleaning systems, and a central automatic control system.

Stationary Crushing Lines: Customized Solutions Built On Site Specifics, Raw Materials, And Product Needs

200tph Granite Crushing Production Line

- Raw Material: Granite

- Capacity: 200 tons/hour

- Location: Somalia

- Configuration: C100 jaw crusher + PFW1315 impact crusher + 4YK2160 vibrating screen

- Project: Aggregate Production for Road Construction

Customer Review: "From installation and commissioning to daily operation, this production line has performed exemplary. The C100 jaw crusher has a strong feed capacity, the PFW1315 impact crusher produces stones with excellent particle shape, and the vibrating screen separates them clearly. Although granite is very hard, equipment wear is within a controllable range, and maintenance is convenient. "

300 tph Pebble Crushing Production Line

- Raw Material: Pebble Stone

- Capacity: 300tph

- Location: Tajikistan

- Configuration: C-series jaw crusher + 2 Simons cone crushers + 2 vibrating screens + sand making machine + belt conveyor

- Finished Product Size: 0-5mm, 5-10mm, 10-20mm, 20-25mm

- Project: Road Construction Aggregate Production

Ulasan pelanggan: "This production line not only consistently meets output targets but also excels in quality control. Cobblestones are inherently difficult to crush, but the finished aggregate has uniform particle shape and low needle-like/flaky content, fully meeting the requirements for road base and surface layer construction.”

200-300tph Basalt Crushing Production Line

- Raw Material: Basalt

- Capacity: 200-300 t/h

- Location: Mexico

- Configuration: ZSW1149 feeder + C110 jaw crusher + PFW1320 impact crusher + 3YK2470 vibrating screen + belt conveyor

- Finished Product Size: 0-3mm, 3-25mm, 25-76mm

- Project: Road Aggregate Production

Ulasan pelanggan: “This production line perfectly meets the stringent environmental and production standards of Mexico. It not only efficiently processes high-hardness basalt, but also produces aggregates with excellent particle shape and stable gradation, fully meeting the highest material quality requirements of our highway project.”

The Global Standard for On-Site Processing: Stone Crushers Equipment

Our family of crushing equipment includes a full range of products, including jaw crushers, cone crushers, impact crushers, and mobile crushing plants, capable of meeting various crushing needs from mining to urban solid waste recycling. We provide intelligent crushing and screening solutions covering the entire process of primary crushing, secondary crushing, fine crushing, and sand making.

PE Series Jaw Crusher

Primary crushing station, coarse crushing unit, high-efficiency coarse crushing solution

- Capacity: 5-1200 t/h

- Feed size: ≤ 1200mm

- Output size: 25-300 mm

Main application areas/scenarios:

- Primary crushing in large mines/open-pit mines: Iron ore, copper ore, gold ore, limestone, granite, and various other metallic and non-metallic ores;

- Quarries and construction aggregate production lines: Basalt, river pebbles, construction waste, concrete blocks, etc.;

- Temporary crushing at construction sites: Temporary crushing needs for road infrastructure, water conservancy and hydropower projects, urban renewal and transformation, etc.

| Model |

Feeder Opening Size(mm) |

Max. Feeding Size (mm) |

Outlet adjusting Size(mm) |

Capacity (t/h) |

Motor Power (kw) |

Overall Dimension (mm) |

|---|---|---|---|---|---|---|

| PE250x400 | 250x400 | 210 | 25-60 | 5-20 | 15 | 1215x1240x1210 |

| PE400x600 | 400x600 | 350 | 40-90 | 15-60 | 30 | 1700x1750x1680 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-130 | 45 | 2150x1900x1950 |

| PE600x900 | 600x900 | 500 | 60-125 | 90-180 | 55 | 2500x2010x2350 |

| PE750x1060 | 750x1060 | 630 | 60-150 | 110-380 | 110 | 2630x2310x3110 |

| PE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 132 | 3720x2850x3250 |

| PE1000x1200 | 1000x1200 | 850 | 200-300 | 280-560 | 160 | 3820x2850x3250 |

| PE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 220 | 4590×3342×3553 |

| PE1500x1800 | 1500x1800 | 1200 | 210-360 | 520-1100 | 280 | 5100x4700x4300 |

PF Series Impact Crusher

High-efficiency secondary crushing equipment designed specifically for medium-hard materials

- Processing Capacity: 15-800 t/h

- Feed Size: ≤ 700 mm

- Motor Power: 45-355kw

Main Application Areas/Scenarios:

- Construction aggregate production lines (secondary crushing stage): Medium-hard materials such as limestone, dolomite, shale, and construction waste;

- Mining crushing systems (secondary crushing): Secondary crushing of metal ores such as iron ore, copper ore, and gold ore;

- Cement production lines (limestone crushing): Crushing of limestone before the pre-homogenization stockpile in cement plants;

- Construction waste recycling: Concrete blocks, bricks, rubble, and other construction solid waste.

| Model |

Feeder opening size(mm) |

Max feeding size(mm) |

Rotor size D*L(mm) |

Capacity (t/h) |

Power (kw) |

Overall Dimension (mm) |

|---|---|---|---|---|---|---|

| PF1007 | 450X730 | ≤250 | Φ1000X700 | 15-60 | 45 | 2330x1700x2560 |

| PF1010 | 400X1080 | ≤300 | Φ1000X1050 | 50-90 | 55 | 2330x2010x2560 |

| PF1210 | 450X1150 | ≤400 | Φ1250X1050 | 70-130 | 90 | 2640x2010x2850 |

| PFW1210 | 450X1150 | ≤400 | Φ1250X1050 | 75-140 | 90 | 2900x2000x2600 |

| PFW1214 | 480x1500 | ≤430 | Φ1250X1400 | 100-180 | 132 | 2900x2400x2600 |

| PFW1315 | 860X1520 | ≤500 | Φ1320X1500 | 130-220 | 200 | 3300x2650x2650 |

| PFW1320 | 900X2000 | ≤500 | Φ1320X2000 | 160-350 | 250 | 3350x3175x2720 |

| PFW1515 | 930x1550 | ≤600 | Φ1500X1500 | 200-400 | 280 | 3450x2750x3010 |

| PFW1520 | 930X2040 | ≤700 | Φ1512X2000 | 300-450 | 355 | 3450x3250x3010 |

| PFW1820 | 1620X2040 | ≤700 | Φ1800X2000 | 500-800 | 2 x 315 | 4400x3750x3900 |

CS Symons Cone Crusher

High-performance medium and fine crushing equipment designed for materials of medium and high hardness.

- Processing Capacity: 30-800 t/h

- Feed Size: 35-284 mm

- Motor Power: 75-400 kW

Main Application Areas/Scenarios:

- Mining medium and fine crushing operations: iron ore, copper ore, gold ore, non-ferrous metal ores, etc..

- Sand and aggregate production lines (secondary/tertiary crushing): granite, basalt, limestone, river pebbles, quartzite, etc.;

- Cement production lines: crushing before the pre-homogenization stockpile in cement plants;

- Construction waste recycling: concrete blocks, bricks, rubble, and other construction solid waste.

| Model | Cavity Type | Crushing Cone Diameter(mm) |

Adjusting Range of Discharge Opening(mm) |

Max feeding size (mm) |

Capacity (t/h) |

Motor (kw) |

Overall size (mm) |

|---|---|---|---|---|---|---|---|

| CS75 | Coarse | 900(3') | 25-38 | 150 | 59-163 | 75 | 2450×1820×2100 |

| CS75 | Medium | 900(3') | 13-38 | 85 | 45-91 | 75 | 2450×1820×2100 |

| CS75 | Fine | 900(3') | 6-22 | 35 | 27-90 | 75 | 2450×1820×2100 |

| CS110 | Coarse | 1200(4') | 15-50 | 180 | 110-250 | 110 | 2485×2050×2445 |

| CS110 | Medium | 1200(4') | 10-38 | 130 | 80-180 | 110 | 2485×2050×2445 |

| CS110 | Fine | 1200(4') | 10-31 | 90 | 63-140 | 110 | 2485×2050×2445 |

| CS160 | Coarse | 1295(4 1/4') | 19-50 | 205 | 172-349 | 132 | 2885×2320×2855 |

| CS160 | Medium | 1295(4 1/4') | 16-38 | 178 | 132-253 | 132 | 2885×2320×2855 |

| CS160 | Fine | 1295(4 1/4') | 13-31 | 115 | 109-181 | 132 | 2885×2320×2855 |

| CS220 | Coarse | 1400(4 1/2') | 30-60 | 235 | 210-530 | 220 | 3153×2358×2750 |

| CS220 | Medium | 1400(4 1/2') | 22-45 | 180 | 180-475 | 220 | 3153×2358×2750 |

| CS220 | Fine | 1400(4 1/2') | 19-40 | 100 | 130-260 | 220 | 3153×2358×2750 |

| CS250 | Coarse | 1650(5 1/2') | 30-60 | 228 | 299-635 | 250 | 3410×2620×3350 |

| CS250 | Medium | 1650(5 1/2') | 25-50 | 205 | 258-417 | 250 | 3410×2620×3350 |

| CS250 | Fine | 1650(5 1/2') | 20-45 | 178 | 181-327 | 250 | 3410×2620×3350 |

| CS315 | Coarse | 2135(7') | 31-64 | 314 | 1125-1814 | 400 | 4613×3302×4638 |

| CS315 | Medium | 2135(7') | 25-51 | 284 | 862-1424 | 400 | 4613×3302×4638 |

| CS315 | Fine | 2135(7') | 19-38 | 236 | 544-1034 | 400 | 4613×3302×4638 |

VSI Sand Making Machine

The sand making machine is the core equipment of the manufactured sand production line.

- Processing Capacity: 60-800 t/h

- Feed Size: 0-50 mm

- Motor Power: 110-520 kW

Main Application Areas/Scenarios:

- Manufactured sand production lines: river pebbles, granite, limestone, basalt, construction waste, etc.;

- Dry-mix mortar production lines: production of dry-mix mortar, special mortar, thermal insulation mortar, etc.;

- Concrete mixing plants: sand production for 5-20mm aggregates;

- Construction waste resource utilization: concrete blocks, bricks, rubble, and other construction solid waste.

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | |

|---|---|---|---|---|---|---|

| Capacity (t/h) | Cascade and Center Feeding | 120-180 | 200-260 | 300-360 | 450-520 | 490-600 |

| Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-310 | |

| Feeding Size (mm) | Soft Material | < 35 | < 40 | < 45 | < 50 | < 50 |

| Hard Material | < 30 | < 35 | < 40 | < 45 | < 45 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | |

| Power of the Double Motors (kw) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 | |

| Overall dimension L*W*H (mm) | 3700*2150*2100 | 4140*2280*2425 | 4560*2447*2278 | 5000*2700*3300 | 5100*2790*3320 | |

| Power Source | 380v:50hz | |||||

| Vibrating Sensor | Inspection Scope:0.1-20mm/s, it can be adjusted continuously. | |||||

| Hydraulic Lubrication Station | Power of Double Oil Pump | 2x0.31kw | ||||

| Safety | Double oil pumps make sure supply of oil with; Stop automatically without oil flow or oil pressure; Water cooled; Heating start the motor in winter. | |||||

| Overall Dimension L*W*H (mm) | 820x520x1270 | |||||

| Power of Oil-Box Heater | 2kw | |||||