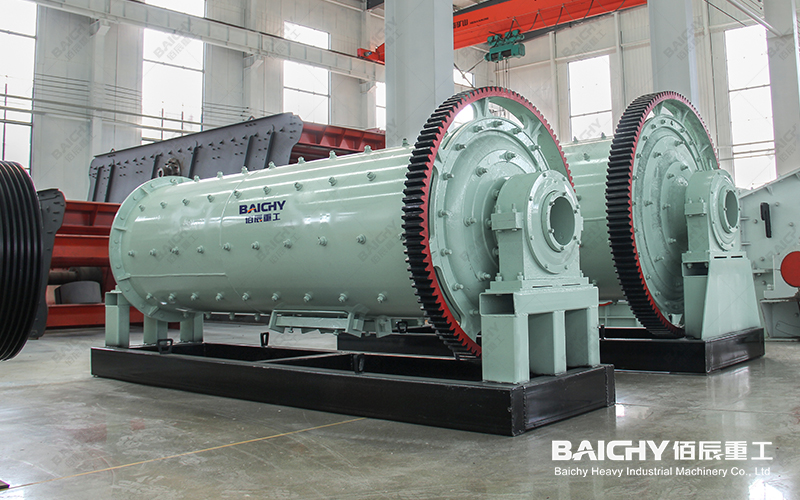

2TPH Ball Mill Manufacturer Recommendation | Designed Specifically for Tanzanian Mining

In Tanzania's booming mining market, small and medium-sized mines and processing plants play a vital role. The demand for a "2tph ball mill" precisely reflects local customers' core need for grinding equipment with medium processing capacity, high cost-effectiveness, and stable operation.

2tph Ball Mill Overview and Application Scenarios

A 2tph (tons/hour) ball mill is a medium-sized grinding equipment widely used in small and medium-scale mining crushing and grinding production lines. Its moderate processing capacity meets the needs of a certain scale of mineral processing while avoiding the problems of excessive initial investment and operating costs caused by overly large equipment.

Basic Specifications

| Model/Specification | MQG 1500×3000 (or according to manufacturer's part numbering system) |

| Cylinder Dimensions | Diameter 1500mm × Length 3000mm |

| Effective Volume | Approx. 4.5-5.0 cubic meters |

| Cylinder Rotation Speed |

28-32 rpm (adjustable, typically 70-80% of critical speed) |

| Maximum Ball Loading | 7-8 tons |

| Feed Particle Size | ≤25mm |

| Discharge Particle Size | 0.074-0.4mm (adjustable) |

Typical Application Scenarios

• Gold and gemstone beneficiation in Tanzania: Fine grinding of gold ore, tanzanite, and other associated ores to achieve liberation or separation particle sizes.

• Small and medium-sized cement raw/clinker grinding: Used for raw material preparation in small cement plants or grinding stations.

• Industrial mineral processing: Grinding of non-metallic minerals such as feldspar, quartz, and barite.

• Laboratory or pilot plant scaling-up: An ideal transitional model from experimental to large-scale production.

Our Recommended Core Advantages of the 2tph Ball Mill

Based on twenty years of technological accumulation and a deep understanding of African working conditions, our 2tph ball mill designed for our Tanzanian customers possesses the following significant advantages:

Design and Durability

• Heavy-duty structural design: The cylinder is constructed from high-strength rolled steel plates, and key components such as the large gear and hollow shaft are made of high-quality alloy steel, ensuring durability and adaptability to Tanzania's continuous operating environment.

• Optimized liners and grinding media: A variety of liner materials (such as high-manganese steel and wear-resistant rubber) and steel balls of different sizes are available, which can be configured according to the hardness and particle size requirements of the ore to maximize grinding efficiency and reduce wear.

Efficiency and Energy Saving

• High-efficiency transmission system: Utilizing advanced reducers or edge drives, the transmission is smooth and efficient, effectively reducing energy consumption and saving customers long-term operating costs.

• Precise particle size control: Equipped with a scientific grading system (such as a spiral classifier or hydrocyclone group), it forms a closed-loop circulation, ensuring uniform particle size and high pass rate of the output product.

Service and Localized Support

• Adaptable design for Africa: Taking into account local climate, voltage fluctuations, and maintenance conditions, the equipment has higher reliability.

• Comprehensive technical support: From basic design and installation guidance to operation training, we provide one-stop service to ensure smooth commissioning of the equipment in Tanzania.

Ball mill South African mineral processing production line

Success Story: Our Cooperation with Tanzanian Clients

We provided a complete mining crushing and grinding production line for a gold mine project in the Mwanza region of Tanzania, with a 2tph wet grate ball mill as the core equipment.

• Customer Challenges: The ore is hard, the existing equipment wears out quickly, consumes a lot of energy, and requires frequent maintenance, impacting production continuity.

• Our Solution: We recommended a 2tph ball mill equipped with high-manganese steel liners and segmented wear-resistant end liners, and reinforced the gear lubrication system.

• Results: The equipment has been running stably for over 3 years. While maintaining the design capacity of 2tph, the grinding fineness has been achieved, and the liner life has been extended by 30%. The customer highly praised its low failure rate and localized spare parts supply service.

Related Equipment Recommendation: Complete Grinding Solution

A high-efficiency ball mill requires perfect coordination with upstream and downstream equipment. We typically recommend the following integrated solution for Tanzanian customers:

1. Crushing Section: Small jaw crusher + cone crusher/fine crusher, providing the ball mill with appropriately sized feed.

2. Feeding Equipment: Electromagnetic vibrating feeder or belt feeder, ensuring uniform and stable feeding to the ball mill.

3. Classification Equipment: Spiral classifier or hydrocyclone assembly, forming a closed loop with the ball mill to improve system efficiency.

4. Auxiliary Equipment: Slurry pump, electrical control system, lifting tools, etc.

Frequently Asked Questions (FAQ)

Q1: What is the approximate footprint and power requirements for a 2tph ball mill?

This depends on the specific model (wet/dry, overflow/grid type) and configuration. Typically, a basic 2tph ball mill occupies approximately 15-25 square meters, and the main motor power ranges from 30-45kW. We can provide precise planning solutions based on your site layout.

Q2: What is the delivery time to Tanzania? What is the warranty period for core components?

For standard models, it typically takes 4-6 weeks from order placement to shipment. Shipping time to Dar es Salaam port is approximately 5-7 weeks by sea. We offer a warranty of no less than 12 months for the core components of our ball mills (such as the cylinder, large gear, and hollow shaft), and provide lifetime technical support.

Q3: Can we send personnel to our factory in China for inspection or site visit?

Of course! We warmly welcome customers from Tanzania and around the world to visit our factory. You can witness the manufacturing process firsthand and conduct on-site testing and acceptance of the ball mills that are about to be shipped, which gives both of us greater confidence.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!