In Canada's coal mining and processing industry, configuring an efficient coal crushing production line to meet production needs of 100-250 t/h requires a comprehensive consideration of factors such as equipment performance, environmental requirements, and operating costs.

The following is an easy-to-understand, yet insightful, professional solution:

1. Advantages of Cone Crusher

Cone crushersare highly favored in coal processing due to their many advantages. They offer a high reduction ratio, breaking coal into finer particles, which is highly beneficial for subsequent coal processing and transportation. Their stable operation and low failure rate ensure continuous production line operation and reduce production interruptions caused by equipment failure. Furthermore, cone crushers have relatively low maintenance costs, and their enclosed design effectively controls dust, complying with Canada's strict environmental regulations.

2. Recommended Core Equipment Selection

For Canadian customers, the following configuration is recommended:

• Cone Crusher: Choose a medium to large hydraulic cone crusher with a rated capacity of 150-300 t/h. This type of equipment is typically equipped with an intelligent control system that automatically adjusts the discharge opening to maintain a stable output. Its highly wear-resistant materials extend equipment life, its energy-saving design helps reduce operating costs, and its easy maintenance minimizes downtime.

• Conveying System: A belt conveyorsystem with a recommended belt width of 800-1200 mm is recommended to ensure efficient material transfer. The conveying system should be dust- and explosion-proof, which is crucial for coal handling. Given Canada's cold climate, the equipment needs to be adapted for low-temperature environments, such as with heating elements or freeze-proof designs.

3. Production Line Configuration Example

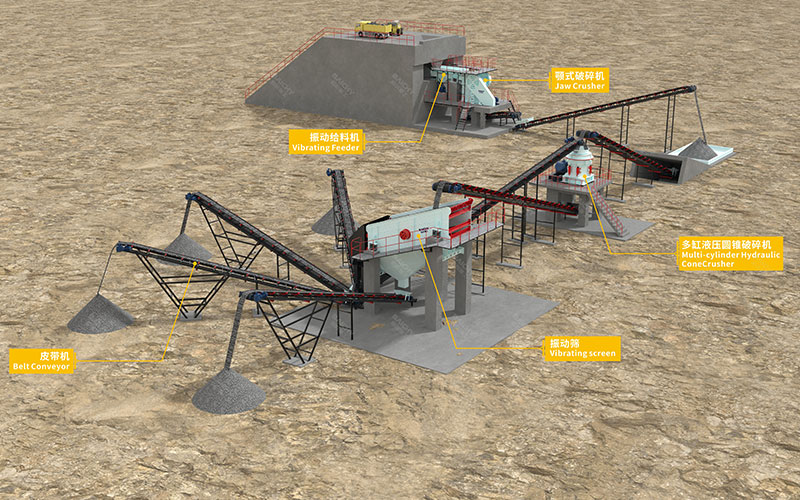

A typical 100-250 t/h coal crushing line might include the following components:

1. Feeding System: A vibrating feeder ensures uniform coal feeding to the crusher.

2. Crushing Unit: A primary cone crusher (e.g., 250 t/h capacity) provides secondary crushing.

3. Conveying System: Multiple belt conveyors connect the crusher, screening equipment, and storage silos, forming a closed-loop process.

4. Auxiliary Equipment: Screens for classification, dust removal systems for dust emission control, and electrical control cabinets for automated control.

4. Key Considerations

- Capacity Flexibility: Choose an adjustable crusher that allows for easy adjustment of capacity within a 100-250 t/h range to adapt to fluctuating market demands.

- Maintenance and Support: In Canada, ensure that the equipment supplier offers local after-sales service and technical support to minimize downtime. Regular maintenance plans should include the replacement of wearing parts (such as liners).

- Sustainability: Integrate energy-saving technologies (such as variable frequency drives) and dust recovery systems to reduce environmental impact. Canadian customers may prioritize solutions with a lower carbon footprint.

Configuring a coal cone crusher production line with a capacity of 100-250 t/h for a Canadian customer requires a comprehensive consideration of equipment performance, local regulations, and operating costs. By selecting a reliable cone crusher and matching conveying system, you can achieve not only efficient production but also long-term economic efficiency and compliance. If you are planning a similar project, we recommend consulting a professional engineer for a customized design to optimize return on investment. Practical applications, such as the use of double-hammer crushers in coal production lines, demonstrate that appropriate crusher selection and configuration can effectively resolve production issues and improve efficiency. Similarly, in the production and processing technology transformation of a building stone mine, significant economic benefits were achieved through technical improvements such as a new loading system, increased effective screening area, and the addition of dust collectors. These cases provide valuable references for coal crushing production line configuration.

In short, when configuring an efficient coal crushing production line for a Canadian customer, it is crucial to fully consider equipment selection, key technical parameters, and industry best practices to meet production requirements, environmental requirements, and operational cost control, ultimately achieving efficient, economical, and sustainable production goals.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)