Detailed Explanation Of Cone Crusher: Working Principle, Types And Application Guide

What Is A Cone Crusher?

Cone crusher is a mining crushing equipment used for medium and fine crushing operations, widely used in sand and gravel aggregates, metal mines, construction waste treatment and other fields. It crushes large blocks of materials (such as granite, basalt, iron ore, etc.) into uniform fine particles through the principle of laminated crushing to meet the requirements of finished product particle size in different industries.

Core Advantages Of Cone Crusher

• High efficiency and energy saving: a hydraulic or spring system is adopted, with large crushing ratio and low energy consumption.

• Excellent finished product particle shape: laminated crushing reduces needle-like particles and is suitable for high-standard aggregate production.

• Strong adaptability: adjustable discharge port to handle high-hardness materials (compressive strength ≤350MPa).

• Automatic control: Some models are equipped with intelligent system to monitor the operating status in real time.

Working Principle Of Cone Crusher

The core of cone crusher is to achieve material crushing through the extrusion and bending between the moving cone and the fixed cone. The specific process is as follows:

1. Feeding stage: The material falls into the crushing chamber from the feed port and is distributed between the moving cone and the fixed cone.

2. Extrusion crushing:

• The moving cone is driven by the eccentric sleeve to make a swivel motion, constantly approaching and moving away from the fixed cone.

• The material is subjected to multiple extrusions, impacts and bending between the moving cone and the fixed cone, and gradually crushed.

3. Layered crushing (laminated crushing):

• The material is not crushed as a single particle in the crushing chamber, but forms a material layer, and the particles squeeze each other, which improves the crushing efficiency and reduces wear.

4. Discharge control:

• The crushed material is discharged downward by gravity, and the size of the discharge port is adjustable (the hydraulic cone crusher can be adjusted automatically).

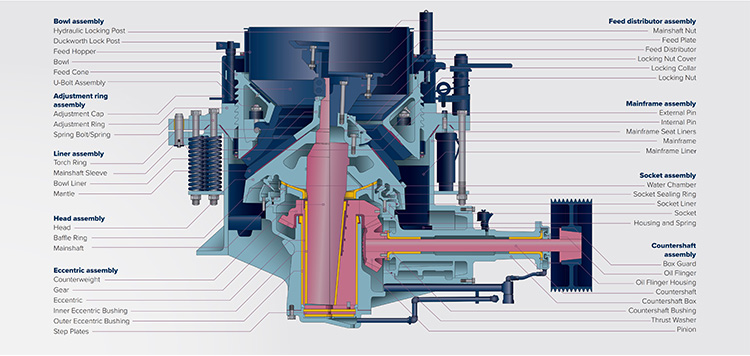

Analysis Of Key Components

• Moving cone (crushing cone): core crushing component, with high manganese steel lining on the surface, strong wear resistance.

• Fixed cone (fixed lining): cooperates with the moving cone to form a crushing chamber, which determines the particle size of the finished product.

• Eccentric sleeve: drives the moving cone to make eccentric rotation to achieve extrusion crushing.

• Hydraulic system (hydraulic cone crusher): provides overload protection and adjusts the size of the discharge port.

Types And Applicable Scenarios Of Cone Crushers

According to different structures and working principles, cone crushers are mainly divided into the following categories:

| Types | Features | Applicable scenarios |

| Spring cone crusher | Adopts mechanical spring overload protection, simple structure, low maintenance cost | Small and medium-sized sand and gravel plants, medium hardness material crushing |

| Hydraulic cone crusher | Hydraulic system adjusts the discharge port, overload protection is more sensitive, and the degree of automation is high | Large mines, fine crushing of high-hardness materials |

| Single-cylinder hydraulic cone crusher | Compact structure, large crushing force, suitable for high production capacity requirements | Large aggregate production line, iron ore crushing |

| Multi-cylinder hydraulic cone crusher | Multi-cylinder coordinated control, more stable operation, better finished product particle shape | High-standard construction aggregate, machine-made sand production |

Frequently Asked Questions about Cone Crusher

1. What is the difference between cone crusher and jaw crusher?

• Jaw crusher: used for coarse crushing, adopts "extrusion + shearing" crushing, feed size is large (≤1500mm), but the finished product size is coarse.

• Cone crusher: used for medium and fine crushing, adopts "laminated crushing", the finished product size is uniform (usually 3-60mm), suitable for high-standard aggregate production.

2. What should I do if the cone crusher is blocked?

• Check whether the feed is uniform to avoid the entry of oversized materials or metal foreign objects.

• Adjust the size of the discharge port or reduce the feeding speed.

• The hydraulic cone crusher can start the cavity clearing function to quickly remove the blockage.

3. How to extend the life of the cone crusher?

• Regularly check the wear of the liner and replace it in time.

• Use suitable lubricating grease (such as Mobil and Shell special lubricants).

• Avoid long-term overload operation and pay attention to the pressure of the hydraulic system.

Cone crusher is the core equipment of modern sand and gravel aggregate and mining crushing. Its high efficiency, energy saving and intelligence make it the first choice for medium and fine crushing operations. Choosing a suitable cone crusher (such as hydraulic or spring type) requires comprehensive consideration of factors such as material hardness, production capacity requirements, and finished product particle size.