With the continuous progress and development of science and technology, the types of quarry crusher equipment are becoming more and more perse. Here we mainly introduce the commonly used mine crushing equipment. The most common and top-ranked crushing equipment are jaw crushers, impact crushers, cone crushers, hammer crushers, and roll crushers. Choose the one that suits your specifications based on the processing material, output, and use. Crushing equipment, so what is the difference between mining equipment? Below I will briefly introduce several commonly used mine crushing equipment.

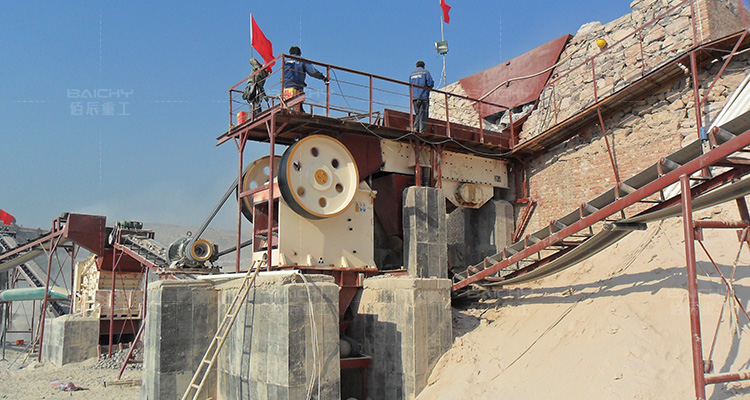

1. Jaw Crusher

First of all, we should know what a jaw crusher is. Jaw crushers are mainly used for primary crushing. The crushing mode is driven extrusion. When the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller. Under the action of the spring, the movable jaw leaves the fixed jaw, and then the crushed materials are discharged from the lower opening of the crushing chamber.

2. Impact Crusher

The impact crusher is a common equipment for rock crushing, and it is the main equipment for medium crushing in the production process. The equipment is made of high-toughness molybdenum-vanadium alloy, which has a series of advantages such as convenient loading and unloading, less wear and tear, and low maintenance cost.

3. Cone Crusher

The cone crusher is composed of a spring, cone, support sleeve, and frame. The adjustment position of the equipment outlet is operated by the operating room of the high-pressure displacement sensor. The motor drives the eccentric sleeve to rotate and swing through the elastic coupling and a pair of bevel gears, and continuously squeezes the materials in the crushing chamber to finally achieve the crushing effect.