In mining production, metal ore crushing is a key link in the mineral processing process, which directly affects the subsequent grinding, sorting efficiency and operating costs. Scientific and reasonable crushing production line design can significantly improve processing capacity, reduce energy consumption and extend equipment life. This article will systematically introduce the core points of metal ore crushing production line design, covering process flow, equipment selection, layout optimization and energy-saving solutions, and provide practical reference for mining companies and engineering and technical personnel.

1. Design process of metal ore crushing production line

1.1 pision of crushing stages

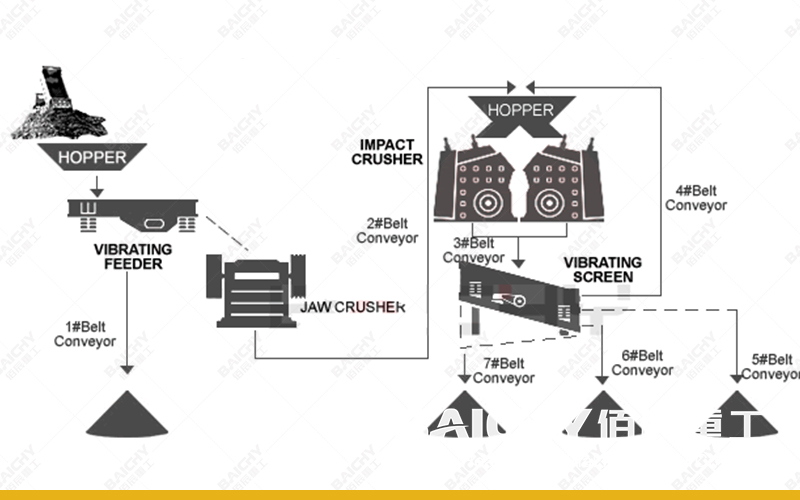

According to the hardness, particle size and target output of the ore, the crushing production line usually adopts a multi-stage crushing process:

• Coarse crushing stage: jaw crusher (processing large pieces of ore, feed particle size ≤1500mm).

• Medium crushing stage: cone crusher or impact crusher (applicable to medium-hard ore).

• Fine crushing stage: high-pressure roller mill or vertical shaft impact crusher (discharge particle size ≤10mm).

• Key parameters: crushing ratio (particle size reduction ratio at each stage), closed circuit/open circuit process selection.

1.2 Screening and circulation design

• Pre-screening: Eliminate qualified particle size materials before coarse crushing to reduce equipment load.

• Closed-loop circulation: Substandard materials return to the crusher to improve the yield rate (recommended with a vibrating screen).

2. Core equipment selection guide

2.1 Coarse crushing equipment: jaw crusher

• Applicable ore: high hardness (such as granite, iron ore).

• Advantages: simple structure and low maintenance cost.

• Selection parameters: feed port size, swing stroke, motor power (example: PE1200×1500, power 160kW).

2.2 Medium and fine crushing equipment: cone crusher

• Hydraulic cone crusher: automatic adjustment of the discharge port, suitable for high-precision requirements (such as copper ore crushing).

• Multi-cylinder cone crusher: large processing capacity and low energy consumption (200-800 tons per hour).

2.3 Auxiliary equipment

• Feeder: electromagnetic vibrating feeder (even feeding, avoid blockage).

• Conveying system: belt width and inclination need to match production capacity (anti-deviation design).

3. Key points for production line layout optimization

3.1 Space planning principles

• Process compactness: reduce material transfer distance and energy consumption.

• Equipment maintenance space: reserve a ≥1.5m channel on the side of the jaw crusher.

3.2 Environmental protection and safety design

• Dust control: crusher seal + pulse dust collector (emission concentration ≤20mg/m³).

• Shock absorption foundation: shock absorption pads are installed on the equipment to reduce noise (≤85dB).

Energy saving and cost control plan

• Frequency conversion technology: adjust the motor speed of the crusher to match the load demand (saving 15%-30% electricity).

• Wear-resistant materials: high manganese steel lining extends the replacement cycle (such as ZGMn13Cr2).

• Intelligent monitoring system: real-time monitoring of bearing temperature and vibration data to prevent downtime.

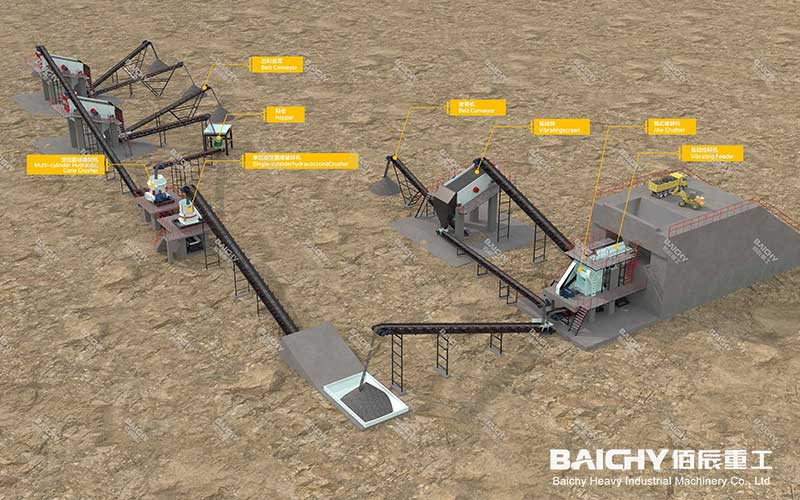

Case: Configuration of 300 tons per hour iron ore crushing line

• Process: coarse crushing (jaw crusher PE900×1200) → medium crushing (HPT300 cone crusher) → screening (3YK3070 vibrating screen).

• Results: finished product particle size ≤12mm, power consumption reduced by 22%, equipment utilization rate reached 90%.

The design of the metal ore crushing production line needs to comprehensively consider the ore characteristics, production capacity requirements and investment costs. Through scientific selection, reasonable layout and intelligent management, production efficiency can be significantly improved. If you need a customized design plan or further technical consultation, please contact our engineering team!

Keywords: metal ore crushing production line | crushing equipment selection | multi-stage crushing process | cone crusher | energy-saving crushing solution

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)