In the field of mining crushing, jaw crusher and cone crusher are two main equipments, which often put users in a dilemma of choice. This article will reveal the essential differences between the two from the perspective of mechanical principles, structural design to application scenarios, and provide a scientific selection methodology.

1. The essential difference in crushing principle: extrusion VS lamination

1.1 The "violent aesthetics" of jaw crusher

The jaw crusher adopts the principle of direct extrusion + splitting crushing, and its working process is like a beast biting:

• The moving jaw plate reciprocates at a frequency of 4-6 times/second

• The maximum crushing force can reach 3000 tons (taking PE1200×1500 as an example)

• The crushing ratio is usually 4-6, which is suitable for primary crushing

Typical case: A granite quarry uses a jaw crusher for primary crushing, and the feed particle size of 1200mm is directly crushed to less than 300mm, and the output of a single machine is 800 tons per hour.

1.2 "Gentle Crushing" of Cone Crusher

The cone crusher adopts the principle of laminated crushing, which is like "Tai Chi" with gradual force application:

• The main shaft is driven by an eccentric sleeve to form a constant crushing chamber

• The material undergoes multiple extrusions in the parallel zone

• The crushing ratio can reach 5-8, suitable for medium and fine crushing

Technological breakthrough: Modern cone crushers use hydraulic adjustment of the discharge port. For example, a certain HPT300 model can adjust the discharge particle size in real time during operation (6-38mm adjustable).

2. The pinnacle of structural design

Comparison table of core components

| Parts | Jaw crusher | Cone crusher |

| Power transmission | Flywheel + toggle plate mechanical transmission | Bevel gear set + eccentric sleeve |

| Crushing chamber | V-type open type | Annular closed type |

| Adjustment mechanism | Gasket adjustment (needs to stop) | Hydraulic adjustment (adjustable during operation) |

| Wear-resistant parts | Manganese steel jaw plate (life 6-12 months) | High chromium alloy lining (life 2-3 years) |

Unique viewpoint: The "positive pressure crushing chamber" design of the cone crusher allows the material particles to squeeze each other when crushing hard rock, which reduces the wear of the liner, which is contrary to traditional cognition.

3. Selection decision tree: 3 key considerations

3.1 Material property test

• Abrasiveness index (Ai)>0.6, cone crusher is preferred

• Jaw crusher is recommended for mud content>15%

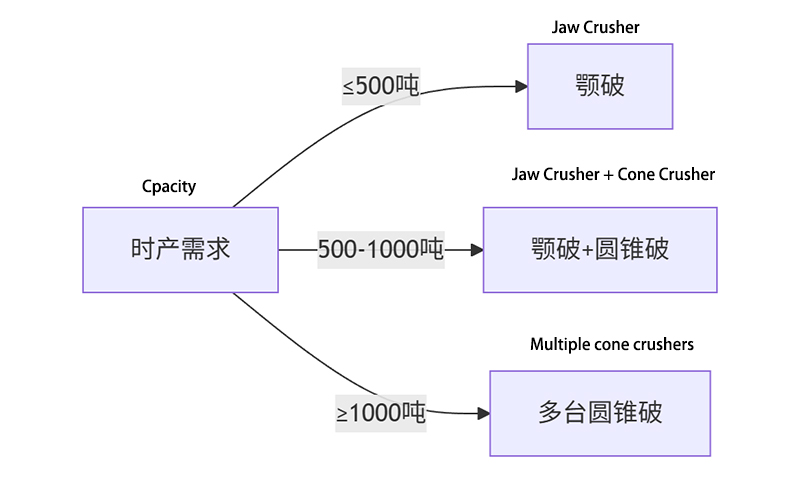

3.2 Capacity demand matrix

3.3 Energy consumption economic analysis

• Jaw crusher: power consumption 0.5-0.7kWh/ton

• Cone crusher: power consumption 0.8-1.2kWh/ton Note: The fine crushing rate of cone crusher can reduce the subsequent mill load by 30%

4. Golden section line of application scenarios

The "main battlefield" of jaw crusher

• Construction waste treatment (including foreign objects such as steel bars)

• Primary crushing of extremely hard rocks such as basalt (compressive strength>250MPa)

• Front-end equipment of mobile crushing station

The "advantage area" of cone crusher

• Secondary crushing of sand and gravel aggregate (finished product cubic content>90%)

• Fine crushing of iron ore and other metal ores (-10mm proportion control)

• Dry sand making pretreatment (3-5mm gradation adjustment)

Industry trend: After the implementation of the new national standard for sand and gravel aggregates in 2024, the finished product gradation pass rate of the cone crusher + vertical shaft impact crusher combination is 22% higher than that of the jaw crusher + impact crusher combination.

5. Hidden ledger of operation and maintenance costs

5.1 "Explicit cost" advantage of jaw crusher

• Infrastructure cost is 30% lower

• It only takes 8 hours to replace the jaw plate

5.2 "Long-distance champion" characteristics of cone crusher

• The life cycle crushing volume of the liner reaches 500,000 tons

• The hydraulic system can realize iron protection and reduce sudden downtime

Operation and maintenance TIP: It is recommended that jaw crusher users be equipped with an online monitoring system, and an early warning will be issued when the toggle plate support temperature is >75℃, which can avoid 60% of sudden failures.

After three years of follow-up testing, a cement group found that in limestone crushing, the combination of jaw crusher (primary crushing) + cone crusher (secondary crushing) reduces total energy consumption by 18% compared with the two-stage jaw crusher solution, and increases the comprehensive utilization rate of equipment by 25%. This confirms the smart choice of segmented crushing and equipment coordination.

Decision-making suggestion: Do material testing before selecting the model. Medium-sized production lines can consider the golden combination of "jaw crusher + cone crusher", which can not only ensure processing capacity but also optimize the quality of finished products. What kind of crushing challenges does your project face? Welcome to leave a message with specific parameters to get customized solution suggestions.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)