Magnetic Separator

I. Introduction: The "Invisible Killer" in Mobile Crushing – Metal Foreign Objects

In busy mining and construction waste processing sites, mobile crushing plants have become core equipment due to their flexible relocation and efficient operation. However, unexpected metal foreign objects such as drill bits, shovel teeth, bolts, and wires mixed in the raw materials act like "invisible killers," posing a huge threat to expensive crushers (such as jaw crushers and cone crushers). A single accidental passage of metal can cause serious damage to rotors, impact plates, and liners, resulting in hours or even days of downtime, leading to significant repair costs and production losses. How to effectively prevent this? Magnetic separation equipment is the mainstay of this defense.

| Key Words |

Magnetic Separator |

| Product Name |

Magnetic Separator |

| Magnetic field intensity (oe) |

1450-1650 |

| Motor Power |

1.1-11kw |

| Capacity |

8-200t/h |

| Core Functions |

By utilizing the magnetic differences between materials, magnetic and non-magnetic substances can be separated in a non-uniform magnetic field. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

II. What is Magnetic Separation Equipment?

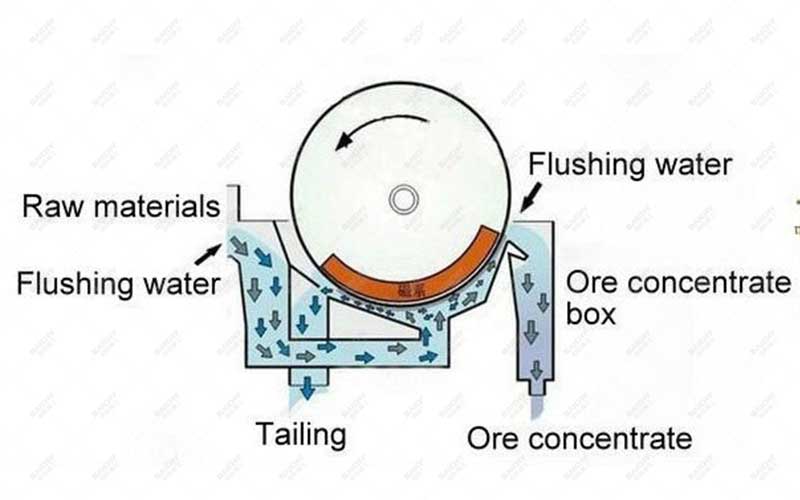

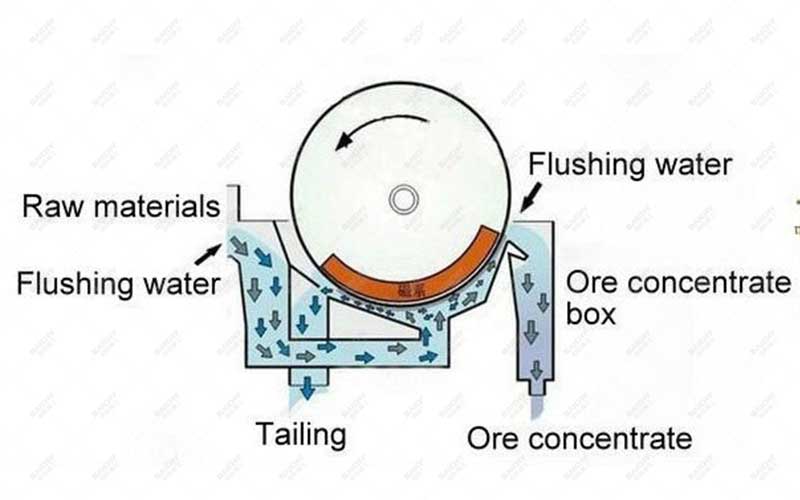

Magnetic separation equipment is designed to remove ferromagnetic metals from the material flow. In mobile crushing and screening production lines, it is usually integrated into the conveyor system in the form of a suspended magnetic separator or a magnetic pulley. Its core principle is to utilize the strong magnetic field generated by high-strength permanent magnets or electromagnets to firmly attract ferrous metals mixed in ore, stone, or recycled aggregates, diverting them from the normal material trajectory, thereby achieving automatic and continuous metal removal and protecting downstream key equipment.

III. Four Core Advantages of Integrating Magnetic Separation Equipment in Mobile Crushing Production Lines

3.1 Ultimate Protection, Reduced Operating and Maintenance Costs

Core Value: Removes metal foreign objects before they contact the crusher rotor, impact plate, or liner, preventing catastrophic damage.

Cost Savings: Greatly reduces the cost of replacing parts due to equipment damage, labor costs for repairs, and the most expensive loss of production downtime.

3.2 Improved Product Purity, Increased Revenue

Quality Assurance: For aggregate or ore products, removing metal impurities effectively improves product purity, meeting higher market standards, especially in the field of construction sand and gravel and high-grade recycled aggregates, where high-quality products mean better prices.

3.3 Enhanced System Automation and Safety

Unmanned Intervention: The equipment operates fully automatically, eliminating the need for manual sorting, reducing safety risks, and adapting to the continuous and efficient operation rhythm of mobile crushing plants. Preventing Secondary Damage: Effectively prevents scratches and punctures to the conveyor belt caused by metal foreign objects, extending the service life of the conveyor.

3.4 Flexible Adaptation, Space Saving

Modular Design: Modern magnetic separation equipment is compactly designed and can be easily integrated into newly purchased or existing mobile crushing plant conveyor systems without extensive modifications to the main structure, making it particularly suitable for mobile equipment layouts with limited space.

IV. Application Scenarios and Case Analysis

4.1 Typical Application Scenarios

Before primary crushing in mines: Removing drilling debris and mechanical parts from raw ore.

Construction waste recycling line: Removing rebar, wire mesh, etc., from reinforced concrete blocks, a crucial step in producing clean recycled aggregates.

Ore crushing production line: Protecting medium and fine crushing equipment (such as cone crushers and vertical shaft impact crushers) to ensure the purity of the final mineral product.

4.2 Case Study: A Construction Waste Treatment Project

Challenge: The customer used our company's mobile impact crusher plant to process construction waste. The material had serious problems with rebar and wire entanglement, frequently causing downtime for cleaning, and the production capacity only reached 60% of the design capacity.

Solution: We installed a suspended strong magnetic iron separator and a magnetic pulley on the feeding conveyor and return conveyor, respectively, forming a double magnetic separation protection system.

Results: The metal impurity removal rate exceeded 95%, equipment downtime due to metal blockage was reduced by more to 90%, the production line recovered and exceeded the design capacity, and the quality of the recycled aggregates produced was significantly improved, resulting in a substantial increase in customer revenue.

V. How to Select the Right Magnetic Separation Equipment for Your Mobile Crushing Plant?

5.1 Main Types of Magnetic Separation Equipment

Suspended Self-Discharging Iron Separator: Suitable for installation above the conveyor belt, handling thick layers of material, and can automatically discharge iron. It is an ideal choice before primary crushing.

Magnetic Pulley/Magnetic Drum: As an active drive roller, it can attract metal from the bottom of the material flow, and is particularly suitable for installation at the head of the conveyor for thorough removal.

5.2 Key Selection Factors

Material Characteristics: Throughput, material thickness, particle size, and humidity.

Metal Characteristics: Size, burial depth, and magnetism (ferromagnetic or weakly magnetic). Installation Space: Mobile crushing plants have a compact layout, requiring precise measurement of available installation space.

Magnetic Field Strength: Choose standard or high-strength magnetic equipment depending on the application requirements.

VI. Frequently Asked Questions (FAQ) about Magnetic Separation Equipment

6.1 Can magnetic separation equipment remove all metals?

No. Standard magnetic separation equipment primarily targets strongly magnetic metals such as iron and steel. For non-ferromagnetic metals such as stainless steel, aluminum, and copper, other technologies such as eddy current separators are required. The main target for removal should be clearly defined during equipment selection.

6.2 Will installing magnetic separation equipment affect the capacity of my existing production line?

Almost certainly not. Magnetic separation equipment itself does not consume processing time; it is integrated into the conveying process and performs separation simultaneously. With proper selection and installation, it will not create a bottleneck in material throughput, and instead, by protecting the main equipment, it ensures the continuous and efficient operation of the production line.

6.3 Does the equipment require complex maintenance?

No. High-quality permanent magnet separators require virtually no maintenance and consume no operating energy. Electromagnetic separators require electricity, but maintenance is relatively simple, mainly involving periodic inspection of the coils and iron removal mechanism. Overall, they are highly reliable and low-maintenance devices.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!