In the fields of mining, sand and gravel aggregate production, etc., choosing the right crushing equipment directly affects production efficiency and economic benefits. Faced with the two mainstream equipment, jaw crusherand cone crusher, many users often fall into a dilemma of choice. This article will provide you with a comprehensive and unique selection guide from the perspective of practical application.

1. Essential difference: philosophical comparison of two crushing principles

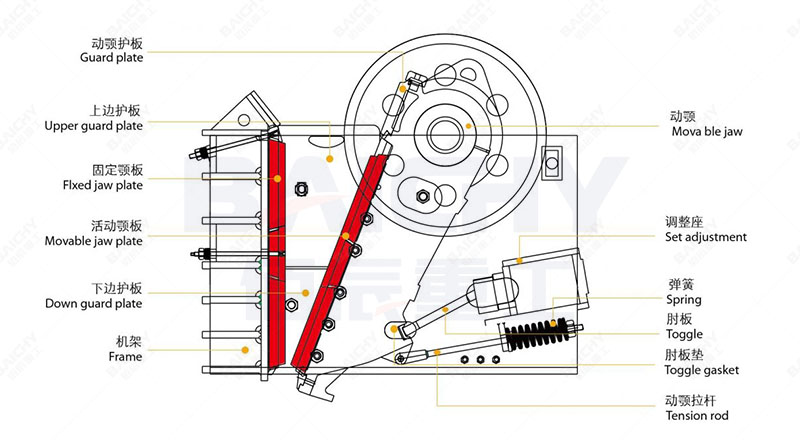

1.1 The "simple and crude" philosophy of jaw crusher

The jaw crusher adopts the most primitive extrusion crushing principle, and crushes materials through the reciprocating motion of the movable jaw plate and the fixed jaw plate like a "vice". This design has been widely used for more than 160 years since it was invented by American Eli Whitney Blake in 1858. Its core advantages are:

• Simple structure: few parts and easy maintenance

• Strong adaptability: can handle materials of various hardness

• Not afraid of "hard food": high tolerance for materials with high mud content and high moisture content

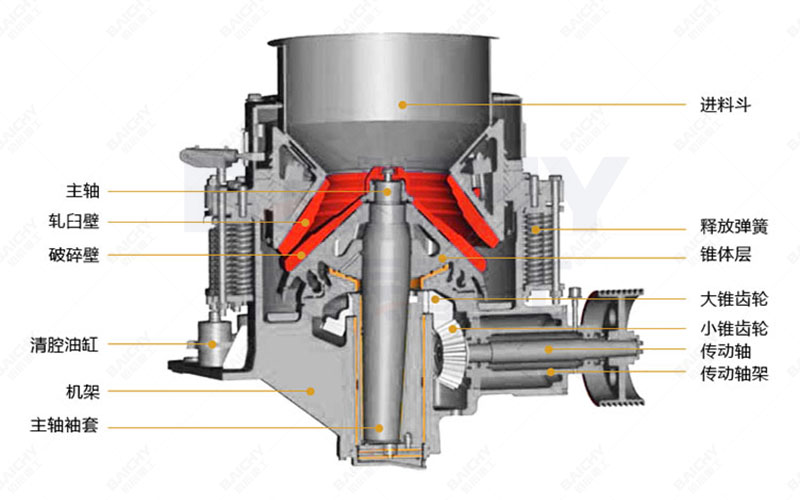

1.2 The "fine processing" philosophy of cone crusher

The cone crusher adopts the principle of laminated crushing, and achieves material crushing through continuous extrusion and grinding between the moving cone and the fixed cone. This equipment, which was born in the early 20th century, represents the evolution of crushing technology:

• Large crushing ratio: a single machine can achieve a high crushing ratio

• Energy consumption economy: energy consumption per unit output is 30-40% lower than that of jaw crusher

• High-quality finished product: good particle shape, low needle-like content

Industry cold knowledge: the research and development inspiration of modern cone crusher comes from coffee grinders. Engineers found that the conical structure can achieve a more uniform crushing effect.

2. Five-dimensional decision-making model: breaking the conventional selection ideas

Traditional selection guides often only focus on equipment parameters, while ignoring the integrity of the production system. We propose a "five-dimensional decision-making model" to help you make a more scientific choice:

2.1 Three dimensions of material characteristics

| Features | Advantages of jaw crusher | Advantages of cone crusher |

| Hardness | Good wear resistance, suitable for high hardness materials | Suitable for medium hard materials, ultra-high hardness wears quickly |

| Viscosity | Not easy to block | Sensitive to sticky materials |

| Water content | Can handle materials with water content below 8% | It is recommended to control it below 5% |

Unique suggestion: For basalt with high mud content, a combination of "jaw crusher + ore washer" can be used instead of directly using a cone crusher

2.2 Dual consideration of process requirements

• System matching degree: When the jaw crusher is used as a coarse crusher, it can be matched with an impact crusher; the cone crusher is more suitable for forming a sand and gravel co-production system with a vertical shaft impact crusher

• Environmental protection requirements: Modern cone crushers have better sealing performance, and dust emissions are more than 50% lower than jaw crushers

3. New algorithm for economic benefits: not just equipment price

Most users only compare the equipment procurement cost, but ignore the life cycle cost (LCC). We recommend the following calculation formula:

Total cost of ownership = purchase cost + (power consumption × annual operating hours × electricity price × service life) + maintenance cost + replacement cost of wearing parts

Take a 200-ton granite crushing line as an example:

• Jaw crusher solution: initial investment is 30% lower, but the total cost in 3 years may exceed

• Cone crusher solution: electricity bill savings can reach 150,000-200,000 yuan/year

4. Innovative application scenarios: breaking through traditional cognition

4.1 "Non-mainstream" advantages of jaw crusher

• Construction waste treatment: strong tolerance to metal impurities such as steel bars

• Mobile crushing station: The flexibility of the jaw crusher mobile station is much higher than that of the cone crusher

• Emergency production: installation and commissioning only takes 1-2 days

4.2 "Black technology" application of cone crusher

• Intelligent adjustment: modern cone crusher can adjust the discharge port in real time through the hydraulic system

• Sand and gravel co-production: Aggregates and machine-made sand can be produced simultaneously through cavity conversion

• Ultrafine crushing: Specially designed cone crusher can crush materials to less than 5mm

5. Future trend: Enlightenment of next-generation crushing technology

With the development of intelligent manufacturing, the two types of equipment are integrating their respective advantages:

• Hybrid crusher: Combining the feeding advantage of jaw crusher and the crushing efficiency of cone crusher

• AI optimization system: Automatically adjust parameters through machine learning to blur the boundaries between the two

• Modular design: Realize rapid conversion between jaw crusher and cone crusher

Choosing crushing equipment is like choosing a combat weapon - jaw crusher is like a reliable pistol, simple and durable; cone crusher is like an accurate sniper rifle, professional and efficient. Our suggestions are:

• Coarse crushing: Jaw crusher is preferred in 90% of cases

• Secondary crushing: Cone crusher is preferred when the output is >200t/h

• Special needs: Cone crusher is a must when the particle shape is important or sand making is required

The final decision should be based on your specific working conditions, investment budget and long-term planning. It is recommended to bring material samples to consult professional engineers and make a decision after the crushing test.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)