Magnetic Separator

Introduction: A Shift in Perception from "Accessory" to "Core Process Equipment"

In mobile crushing and screening production lines, equipment such as vibratory feeders, jaw crushers, cone crushers, and vibrating screens are undoubtedly at the core of the process, determining production capacity and product particle size. However, an efficient and stable process flow requires not only "offensive" crushing equipment but also "defensive" protective equipment. Magnetic separators are precisely such a critical yet often underestimated piece of process equipment. They are not simply "accessories," but rather the cornerstone for ensuring the continuous, safe, and efficient operation of the main process equipment, representing a strategic investment in optimizing the overall process flow, reducing overall operating costs, and increasing the value of the final product.

| Key Words |

Magnetic Separator |

| Product Name |

Magnetic Separator |

| Magnetic field intensity (oe) |

1450-1650 |

| Motor Power |

1.1-11kw |

| Capacity |

8-200t/h |

| Core Functions |

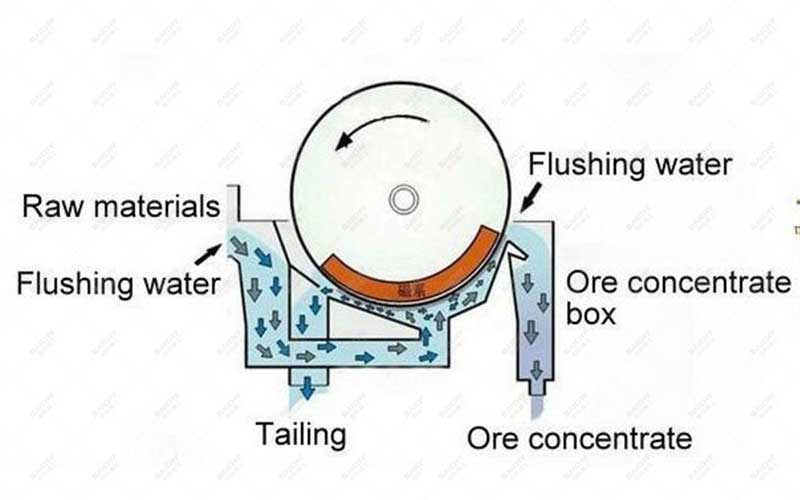

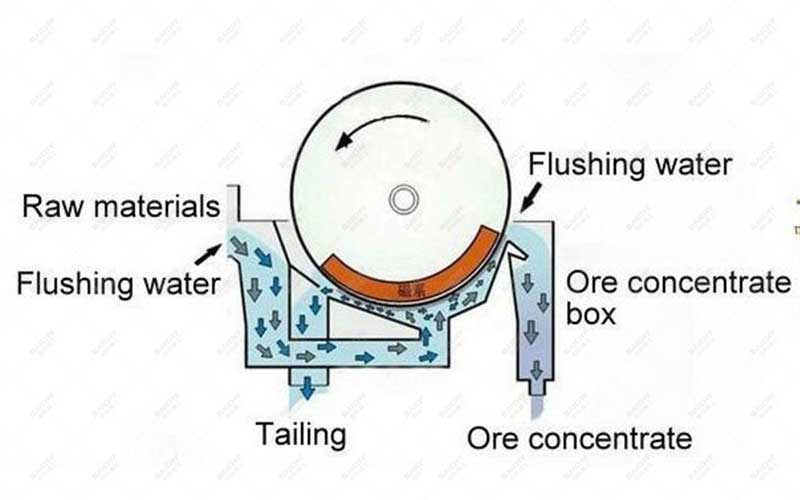

By utilizing the magnetic differences between materials, magnetic and non-magnetic substances can be separated in a non-uniform magnetic field. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Magnetic Separators: Definition and Role in the Process Flow

A magnetic separator is an industrial device specifically designed to automatically and continuously separate and remove ferromagnetic metal impurities from a moving material stream using magnetic force. In mobile crushing processes, its core role is reflected in several key process nodes:

The starting point of raw material pretreatment: Installed on the primary feeder or main receiving conveyor belt, acting as the "first line of defense" before materials enter the crushing cycle.

The "personal bodyguard" of critical equipment: Installed close to the feed inlet of secondary and tertiary crushing equipment (such as cone crushers, impact crushers, and sand making machines), providing direct protection for the core machinery.

The "purifier" of the circulating load: Installed on the return conveyor belt of a closed-loop system, continuously removing metal impurities newly exposed during the circulation process due to wear or other reasons, preventing their accumulation in the system.

The "quality gatekeeper" of the final product: Performing a final magnetic separation before the finished aggregate is transported to the stockpile or loaded onto trucks, ensuring the purity of the finished product and meeting high market standards.

Four Core Values of Integrating Magnetic Separators into Process Equipment

1. Enhancing the Reliability and Continuity of the Overall Process Flow

Reducing unplanned downtime: By actively removing metal foreign objects that cause equipment jamming, overloading, or severe wear, magnetic separators transform sudden, destructive downtime into predictable preventive maintenance, greatly improving the operating rate and capacity utilization of the entire mobile crushing and screening unit. 1. Stable Process Parameters: A stable, metal-contamination-free material flow ensures that process parameters such as crushing chamber lamination effect and screening efficiency remain optimal, resulting in more stable and better-shaped products.

2. Significantly Reduced Total Life Cycle Operating Costs

Direct Savings: Significantly reduces abnormal wear and tear on core crusher wear parts (such as blow bars, mantle liners, and liners), lowering the frequency and cost of parts replacement.

Indirect Savings: Reduces repair labor costs and downtime losses due to equipment damage, as well as costs associated with premature conveyor belt damage caused by metal impurities.

3. Optimized Product Quality and Expanded Market Applications

Improved Product Purity: Effective removal of metal impurities is a key process step in the production of high-quality concrete aggregates, asphalt aggregates, and various grades of recycled aggregates. Pure aggregates improve concrete strength and durability and prevent the risk of rebar corrosion.

Creating Product Value: The separated scrap steel can be sold as a byproduct, achieving full resource utilization and generating additional revenue for operations.

4. Enhanced System Automation and Safety

Unmanned Operation: Modern self-discharging magnetic separators can automatically remove iron without manual intervention, aligning with the development trend of intelligent and automated mining equipment, and eliminating safety hazards associated with manual cleaning near operating equipment.

Process Integration Case Study: Mobile Hard Rock Crushing Production Line

Project Background: The customer purchased a set of our tire-mounted jaw crusher + cone crusher + screening three-in-one mobile station for crushing high-hardness basalt to produce high-end aggregates.

Process Flow Pain Points: The raw materials after blasting often contain unexploded drill bits, alloy teeth, and other ultra-hard metals. In traditional processes, these metals easily cause "over-iron" in the cone crusher, resulting in damage to core components such as the main shaft and bushings, leading to high repair costs and long downtime.

Our Process Equipment Integration Solution:

Node A (Before Coarse Crushing): Install an RCDD series suspended self-discharging electromagnetic iron separator on the feeding conveyor of the mobile jaw crusher to remove most of the large metal pieces and protect the jaw crusher.

Node B (Before Secondary Crushing): Before the material is transported from the jaw crusher outlet to the cone crusher via conveyor belt, an RCT series permanent magnetic self-discharging iron separator is installed at the transfer point for secondary fine iron removal.

Node C (Circulation Loop): A magnetic drum is installed on the return conveyor belt of the closed-circuit screening system to continuously purify the circulating material.

Process Effectiveness: A three-stage magnetic separation process protection chain of "primary interception - precision removal - circulation purification" has been formed. Since the system was put into operation, the cone crusher has not experienced a single "iron overload" failure caused by metal, and the equipment availability rate is as high as 98%. Customer feedback indicates that the production guarantee provided by the equipment's reliability enabled them to successfully secure orders for high-speed rail projects with extremely high requirements for aggregate quality and supply stability.

How to choose the right magnetic separation equipment for your process?

Key Selection Parameters: Closely tied to the process

Material Characteristics: Throughput (t/h), maximum particle size, bulk density, moisture content, and whether the material itself is magnetic.

Process Location: Determining whether the equipment is installed at the feeding end, before crushing, or in the circulation loop, which determines the choice of magnetic field strength, suspension height, and iron discharge method.

Metal Characteristics: The expected size, shape, burial depth, and magnetism of the metal to be removed.

Equipment Interface: Conveyor belt width, belt speed, and spatial compatibility with adjacent process equipment.

Recommendations from the Equipment Manufacturer

We not only provide the main equipment but also complete process solutions. Our technical team will consider the selection, installation location, and control logic of the magnetic separator in conjunction with the overall process flow during the project design phase. We recommend:

Permanent Magnetic Equipment: No energy consumption during operation, simple maintenance, suitable for most working conditions, and the preferred choice for mobile stations.

Electromagnetic Equipment: Adjustable and controllable magnetic field, suitable for scenarios with extremely thick material layers or special requirements for discarded iron.

Systematic Configuration: For complex or high-value materials, we recommend using a "magnetic separation system" with multiple equipment combinations to achieve the best protection effect.

Frequently Asked Questions (FAQ) about Magnetic Separators (Process Equipment)

FAQ 1: Do magnetic separators consume a lot of energy and increase operational complexity?

Answer: This is a common misconception. Currently, the mainstream permanent magnet iron separators/magnetic drums utilize high-performance neodymium-iron-boron permanent magnet materials as their core magnetic source. They consume no electricity during operation, achieving true zero-energy consumption. Their simple structure, lack of complex and easily damaged parts, and virtually maintenance-free operation do not increase the complexity of the process flow; instead, by protecting the main equipment, they greatly simplify operational management.

FAQ 2: Are magnetic separators ineffective for non-magnetic metals such as stainless steel? Are there other process equipment options?

Answer: Yes, traditional magnetic separators are ineffective for austenitic stainless steel (such as 304 and 316) and non-ferrous metals such as aluminum and copper. For these "difficult metals," another key piece of equipment—an eddy current separator—needs to be integrated into the process flow. It utilizes an alternating magnetic field to induce eddy currents in non-ferrous metals, generating a repulsive force to separate them. In processing lines for construction waste, electronic waste, and non-ferrous metal recycling, it is often used in conjunction with magnetic separators to achieve comprehensive separation of ferrous and non-ferrous metals.

FAQ 3: We plan to purchase a new mobile crushing plant. Should we purchase a magnetic separator as a standard configuration?

Answer: We strongly recommend "yes." Based on our many years of experience as a manufacturer, integrating the magnetic separator with the main equipment during the design, manufacturing, and installation phases offers significant advantages: 1) Optimal layout: Installation location and electrical/control interfaces can be planned in advance, resulting in the most compact and efficient design. 2) Lower cost: Saves on engineering and adaptation costs for later modifications. 3) Timely protection: Provides protection from the first day of operation, avoiding the passive situation of "damage first, then repair." We usually offer flexible configuration packages, allowing customers to choose basic or enhanced magnetic separation configurations based on their material characteristics.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!