In the fields of mining, construction waste treatment, road construction, etc., mobile crushing stationsare gradually becoming the preferred equipment in the crushing industry due to their flexible transfer and efficient operation. So, what are the key components of it? Compared with traditional fixed crushing equipment, what are its irreplaceable advantages? This article will analyze it in detail for you.

Composition structure of mobile crushing station

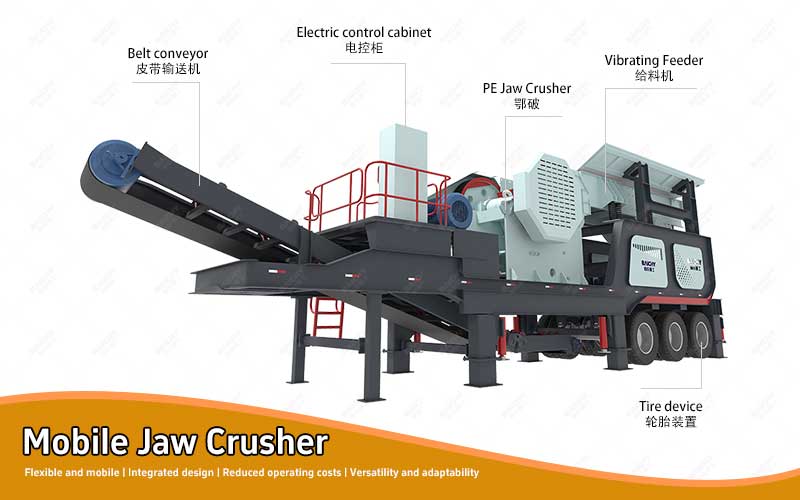

Mobile crushing station is not a single device, but a modular integration of multiple systems, mainly including:

1. Feeding system

• Vibrating feeder: uniformly convey materials to avoid crusher blockage.

• Pre-screening device (optional): separate fine particles in advance to improve efficiency.

2. Crusher host

• Jaw crusher (coarse crushing), impact crusher/cone crusher (medium and fine crushing), etc., flexibly selected according to the hardness of the material.

3. Screening system

• Multi-layer vibrating screen: classify the crushed materials according to particle size, and return unqualified materials for re-crushing.

4. Conveying system

• Belt conveyor: connect each module to realize automatic material flow.

5. Mobile chassis

• Tire type: suitable for short-distance transfer, convenient road traction.

• Track type: adapt to complex terrain, safer remote control operation.

6. Intelligent control system

• Integrated PLC control panel, real-time monitoring of equipment operation status, support fault warning.

Mobile vs. fixed crushing station

| Comparison items | Mobile crushing station | Fixed crushing station |

| Installation cycle | Production within 1 day | 1-3 months infrastructure |

| Transfer flexibility | Can be moved at any time | Not removable |

| Applicable scenarios | Short-term, decentralized projects | Long-term, centralized projects |

How to choose a suitable mobile crushing station?

Choose the main machine by material type:

• Hard rock (granite, basalt) → cone crusher

• Medium and low hardness (limestone, construction waste) → impact crusher

Choose the chassis by terrain:

• Flat site → tire type (low cost)

• Rugged mountainous area → crawler type (strong passability)

According to capacity requirements:

• Small project (50-100t/h) → single machine combination

• Large project (more than 200t/h) → multi-unit joint operation

Mobile crushing station has become an "all-round player" in modern crushing operations due to its modular composition and flexible advantages. If you are looking for a cost-effective, low-investment, and fast-return crushing solution.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)