In the fields of mining, aggregate production, and construction waste recycling, production efficiency, cost control, and environmental requirements are facing unprecedented challenges. Traditional fixed production lines, while stable and reliable, often burden investors with heavy pressure from the outset due to their massive infrastructure investment, rigid layout, and deep dependence on specific mining sites. They are also difficult to adapt to multi-site, decentralized operations and increasingly stringent environmental policies. The emergence of crawler-type mobile crushing plants, like a fully armed "mobile warrior," is revolutionizing production models globally with its unparalleled flexibility and integrated high-efficiency production capabilities. As a leading manufacturer of crushing and sand-making equipment with many years of experience in the industry, we have the responsibility and obligation to provide you with a comprehensive analysis of the core value and application prospects of this groundbreaking equipment.

I. Core Analysis: What is a Crawler-Type Mobile Crushing Plant?

A crawler-type mobile crushing plant is not simply a "crusher mounted on tracks." It is a highly integrated modular crushing and screening system. Its core is the precise deployment of a feeder, crusher (which can be jaw, impact, cone, or hammer type), vibrating screen, conveyor, power control system, and power unit (diesel engine or diesel-electric hybrid) on a high-strength, fully hydraulically driven crawler chassis. It achieves the integration of the complete crushing and screening process from raw materials to finished products, with its own power and mobility. It can move freely within the work area via wireless remote control or cab operation, truly realizing the concept of "bringing the production line to the mine site."

Crawler Mobile Jaw Crusher

Crawler Mobile Impact Crusher

Crawler Mobile Cone Crusher

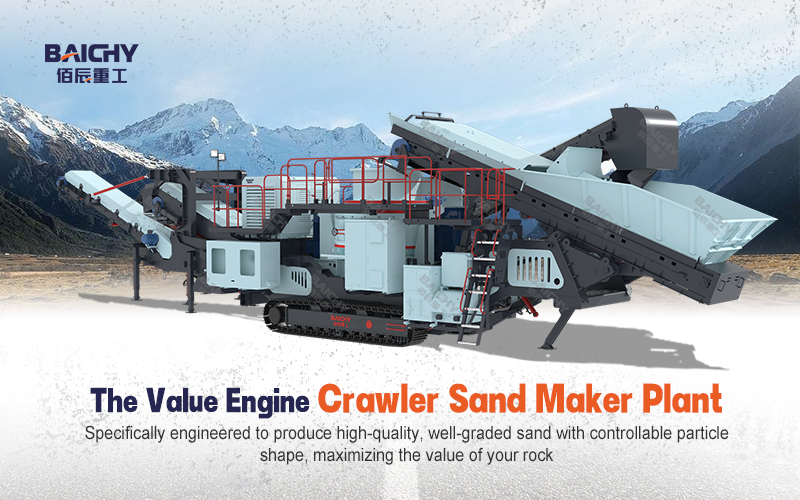

Crawler Mobile Sand Making Plant

II. Baichy Heavy Industry's Value Proposition: We Provide Not Just Equipment, But Solutions

As an equipment manufacturer, our core competitiveness lies in providing customized overall solutions for our customers based on our deep technological expertise. By choosing us, you will receive:

1. Full-Chain Quality Control: From core castings and high-strength steel plate cutting to machining, heat treatment, and final assembly and testing, we achieve full-process independent manufacturing and strict quality inspection of the equipment's "skeleton" and "heart." This means more reliable equipment durability, more stable performance output, and a more competitive cost advantage.

2. Flexible Modular Configuration: We can tailor the most suitable crushing equipment for you based on your specific material characteristics (hardness, humidity, particle size), expected production capacity, and final product specifications (such as aggregates with various gradations). This includes configuring the most appropriate crushing main machine (such as a mobile jaw crusher for coarse crushing, or a mobile cone crusher or impact crusher for medium and fine crushing), and can be combined with a mobile screening plant to form an open or closed-loop production line.

3. Deep Adaptation to Complex Working Conditions: Whether it's the rugged working face of open-pit mines, the complex environment of construction waste disposal sites, or infrastructure construction projects in remote areas, our crawler-type mobile stations can become a powerful tool for overcoming challenges with their excellent passability and rapid deployment capabilities.

III. Six Unparalleled Core Advantages

Ultimate Mobility and Flexibility: This is its most significant advantage. The equipment can move, steer, and position itself under remote control commands, like a "Transformer." For multi-mining area mines, it can "move from one place to another," significantly reducing the transportation distance of mining trucks; for linear engineering projects (roads, railways), it can closely follow the project progress, enabling on-site material sourcing, processing, and use.

Significantly Reduced Overall Operating Costs:

1. Reduced Infrastructure Costs: Almost no concrete foundation is required, saving a large amount of initial civil engineering investment and time.

2. Reduced Transportation Costs: Achieves "materials to the equipment," rather than "equipment to the materials," greatly reducing raw material handling costs.

3. Reduced Labor Costs: Intelligent centralized control makes multi-machine operation by a single person possible, with a high degree of automation.

4. Rapid Commissioning and Improved Return on Investment: After the equipment arrives on site, it can be positioned, debugged, and put into production within a few hours, significantly shortening the project's capital recovery cycle. This "ready-to-use" feature helps investors quickly seize market opportunities.

Powerful Environmental Adaptability and Environmental Protection Capabilities:

1. Adaptability to Complex Terrain: The crawler chassis has low ground pressure, strong climbing ability, and can move freely on wetlands and mountainous areas.

2. Green Production: Equipped with dust removal and noise reduction systems, it effectively controls dust and noise pollution. In the field of construction waste treatment, it is a core equipment for achieving resource recycling, conforming to the global trend of sustainable development. Integrated

3. Intelligent Control: Integrating advanced PLC electrical control and intelligent monitoring systems, it can monitor key data such as equipment operating status, output, and power consumption in real time, enabling fault warning and remote diagnosis, ensuring efficient, safe, and stable operation of the equipment.

4. Creating Diverse Profit Models: One piece of equipment can be used not only for primary crushing of raw ore but also easily transferred to construction waste disposal sites, demolition sites, etc., to carry out urban mining operations and broaden profit channels.

IV. Comprehensive Overview of Application Scenarios

1. Mining: Primary crushing and subsequent processes for various metal and non-metallic mines.

2. Sand and Gravel Aggregate Production: Aggregate processing for river sand mining and stone quarries, especially suitable for small and medium-sized projects with dispersed resources.

3. Construction Waste Resource Utilization: On-site crushing and screening of construction waste such as concrete, asphalt, bricks, and tiles to produce recycled aggregates, a powerful tool for building "waste-free cities."

4. Infrastructure Construction: On-site processing of subgrade materials for roads, railways, water conservancy, airports, and other projects.

5. Other Fields: Soil remediation, site leveling, etc.

In today's pursuit of high efficiency, low cost, green operation, and intelligence, crawler-type mobile crushing stations have been upgraded from "optional equipment" to "strategic equipment." It represents not only an advanced machine but also an innovative production organization model and investment philosophy. As your reliable equipment source partner, we are committed to providing you with the most robust and intelligent mobile crushing solutions through excellent craftsmanship, innovative technology, and full lifecycle services, helping you navigate the fierce market competition, unlock the unlimited value of every ton of resources, and together move towards a highly efficient and green future.

Crawler Mobile Jaw Crusher In Production

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Mobile Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!

Q: What is the biggest advantage of a crawler-type mobile crusher over a traditional fixed crushing plant?

A: The single biggest advantage is unmatched mobility and flexibility. It eliminates the need for costly and time-consuming concrete foundations, can be moved directly to the material source (in-pit crushing), and easily relocated between different sites or along a project length, drastically reducing material haulage costs and setup time.

Q: Can it operate in remote areas without a reliable power grid?

A: Absolutely. Crawler-type mobile crushers are typically equipped with a powerful, self-contained diesel engine (or optional hybrid electric-diesel), providing complete power independence. This makes them the ideal solution for remote quarries, mining sites, or infrastructure projects in areas with unstable or no electrical supply.

Q: As a direct manufacturer, how do you ensure the quality and durability of key components like the crusher jaws and tracks?

A: As a source factory, we have strict in-house control over core components. We use high-grade, wear-resistant materials for wear parts (like manganese steel jaws) and source heavy-duty, reliable crawler undercarriages. Our vertical integration allows for better quality control, cost efficiency, and direct technical support.

Q: What types of materials can your mobile crushers process, and can they produce different sizes of final products?

A: Our crushers are built to handle a wide range of hard and abrasive materials, including granite, basalt, limestone, and construction & demolition (C&D) waste like concrete and asphalt. By pairing with different crusher types (Jaw, Cone, Impact) and mobile screens, we can configure a plant to produce multiple, precisely sized end products (e.g., 0-5mm, 5-10mm, 10-20mm aggregates) in a single or multi-stage process.

Q: What kind of after-sales support and service network do you offer for international clients?

A: We provide comprehensive global support, including professional pre-sales consultation and layout planning, detailed installation & operation manuals, online/offline operator training, and a reliable supply chain for genuine wear and spare parts. We have service engineers available for major commissioning and support, backed by a responsive 24/7 online technical assistance team to minimize your downtime.