Crawler Mobile Jaw Crusher

In today's global mining and aggregate industry, where efficiency, flexibility, and sustainable operations are paramount, equipment selection is no longer a simple purchase, but a strategic investment. As a professional manufacturer of mining crushing and sand-making equipment, we deeply understand the challenges our customers face in complex and ever-changing operating environments. The crawler-mounted jaw crusher, as the cornerstone of mobile crushing solutions, is becoming the preferred choice for numerous projects worldwide, thanks to its unparalleled mobility and reliable performance as the "king of primary crushing." This article will delve into why choosing a professional source manufacturer is key to maximizing the value of this "mobile pioneer."

Crawler-mounted jaw crusher working site

I. Core Value: Why is the Crawler-Mounted Jaw Crusher a Revolutionary Piece of Equipment?

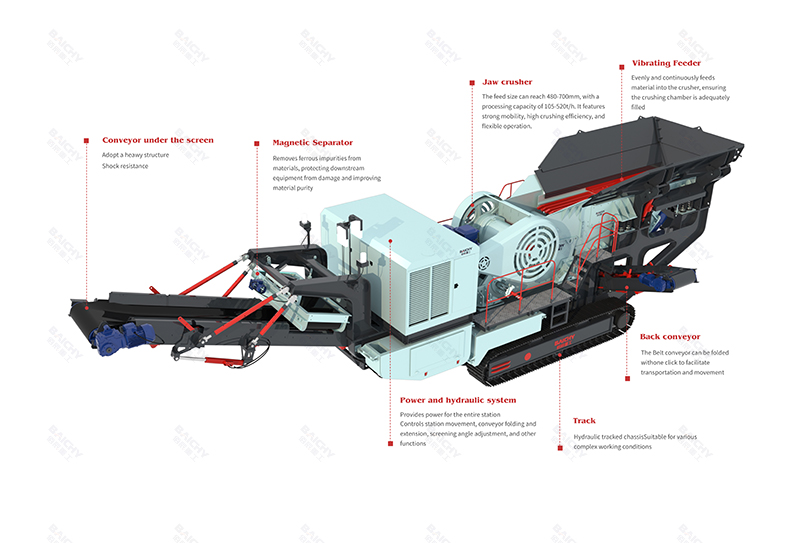

The crawler-mounted jaw crusher is not simply a jaw crusher mounted on a crawler chassis. It is a highly integrated, fully functional, independent mobile crushing unit, whose core components include:

1. Heavy-duty jaw crusher: As the "iron stomach," it is responsible for the first and most crucial coarse crushing process of various hard materials (such as granite, basalt, river pebbles, and construction concrete).

2. Powerful vibrating feeder: Provides uniform and controlled feeding to the crushing chamber, preventing blockages and maximizing crushing efficiency.

3. Robust crawler chassis: Fully hydraulically driven, providing excellent traction, climbing ability, and adaptability to rough terrain, enabling self-propelled movement and precise positioning of the equipment.

4. Power and intelligent control system: Typically powered by a high-efficiency diesel engine and integrated with an advanced PLC control system for one-button operation, remote monitoring, and fault diagnosis.

This integrated design makes it a "mobile primary crushing workshop," capable of directly moving to the raw material source, completely transforming the high-cost, low-efficiency model of traditional fixed production lines where "raw materials are transported to the equipment."

II. Five Core Advantages of Choosing a Source Manufacturer

Unlike working with traders or private label manufacturers, choosing us, a source manufacturer, gives you direct access to the core benefits at the top of the value chain:

Superior Mechanical Performance and Durability Guarantee:

1. Core Structure: From high-strength steel plate cutting and frame welding (using stress-relieving processes) to the casting and machining of key components such as the core jaw and eccentric shaft, we implement rigorous in-house standards. This ensures the structural integrity and long-term stability of the equipment when subjected to immense crushing forces.

2. Jaw Plates and Wear Parts: As a source manufacturer, we use top-grade alloy steel (such as the ZGMn13 series) and optimize cavity design to produce jaw plates with longer lifespan and higher crushing efficiency, directly reducing your cost per ton of consumables.

Deep Customization Flexibility:

We don't offer "standard answers," but rather "customized solutions." Based on your material hardness, size, humidity, and target capacity, we can adjust the feeder size, jaw crusher model (feed opening size, power), and discharge opening adjustment range (hydraulic or wedge type) to ensure the equipment perfectly matches your working conditions.

Significantly Optimized Total Cost of Ownership:

1. Procurement Cost: By eliminating intermediaries, you will receive more competitive factory prices.

2. Operating Costs: Optimized design reduces fuel consumption; the use of long-life wear parts reduces downtime and replacement frequency.

3. Maintenance Costs: We provide a complete catalog of original spare parts, ensuring you can obtain perfectly matched genuine spare parts at reasonable prices, avoiding secondary damage caused by inferior parts.

Comprehensive Professional Technical Support:

From initial project site condition assessment and equipment selection recommendations to installation and commissioning guidance and on-site operator training, we provide professional services throughout the entire process. Our team of engineers understands every detail of the equipment, inside and out, and can provide the most direct and effective solutions.

Future-Oriented Solution Scalability:

A crawler-mounted jaw crusher can function as a powerful and independent work unit, or as the "leading" component of a mobile crushing and screening production line. We can provide seamlessly integrated crawler-mounted cone crushers, impact crushers, or screening plants, offering you a one-stop, homogeneous solution for future production line expansion and upgrades.

III. Typical Application Scenarios and Investment Returns of Track-Mounted Jaw Crushers

1. Hard Rock Mining: Moving within rugged mining areas, performing the first stage of coarse crushing on blasted ore, significantly reducing transportation distances and energy consumption of mining trucks.

2. Sand and Gravel Aggregate Production: Particularly suitable for projects with dispersed resource points and short mining cycles, enabling efficient "move-and-crush" operations and rapid return on investment.

3. Construction Waste Recycling: Directly crushing large pieces of construction waste such as concrete and bricks at demolition sites to produce recycled aggregates, a core equipment for achieving both environmental protection and profitability.

4. Infrastructure Construction: On-site production of base aggregates for roads, railways, and water conservancy projects, saving significant material transportation costs.

5. Quarry Expansion: As a supplement to existing fixed production lines or a pre-processing unit for primary crushing, flexibly responding to capacity fluctuations.

In a rapidly changing market, investing in a high-performance, highly reliable track-mounted jaw crusher means you gain strategic control over production efficiency, operational flexibility, and cost control. As your reliable source manufacturing partner, we are committed to ensuring that you purchase not just a machine, but an asset that continuously generates value, through our solid industrial manufacturing technology, deep understanding of application scenarios, and sincere long-term service. Let's work together to lay a solid foundation for each of your projects with reliable mobile crushing solutions and jointly create a more efficient and greener future.

The Structure of Crawler Mobile Jaw Crusher

| Key Words |

Crawler-Type Mobile Crusher |

| Product Model |

Crawler Jaw Crusher |

| Capacity |

80-520t/h |

| Core Functions |

Tracked walking systems enable mobile operations |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!

Q: As a direct manufacturer, how do you ensure the structural strength and longevity of the crusher's main frame?

A: We employ Finite Element Analysis (FEA) in the design phase to optimize stress distribution. The frame is constructed from high-tensile strength steel plates, welded with robotic precision and stress-relieved to prevent deformation. This ensures it can withstand the tremendous forces of primary crushing for years.

Q: What are the key advantages of a track mounted jaw crusher for a multi-pit quarry operation?

A: Its primary advantage is in-pit mobility. The crusher can be moved close to the active mining face, dramatically reducing truck haulage distances for raw material. This leads to massive savings in fuel, tire wear, and labor costs, while increasing overall production efficiency as the mine face advances.

Q: Can your track mounted jaw crusher handle tough materials like basalt or granite, and what about wear part life?

A: Absolutely. Our jaw crushers are engineered specifically for hard, abrasive rocks. We use premium-grade manganese steel for jaw plates and configure the crushing chamber geometry for optimal nip angle and crushing action. This combination ensures high reduction ratios and maximizes wear part life, reducing your cost per ton.

Q: What kind of power options and control systems do you offer? Is remote monitoring available?

A: We typically equip our crushers with fuel-efficient, Tier 3/Stage IIIA compliant diesel engines for complete site independence. The standard PLC control system allows for easy operation and monitoring. We also offer optional remote telemetry systems that allow you to track production data, location, and machine health metrics from your office.

Q: What does your after-sales support include for a global customer? How do you handle spare parts delivery?

A: Our support starts with comprehensive documentation and training. We have a network of service engineers and strategically located spare parts depots to ensure rapid response. Customers receive a detailed parts manual, and we utilize a global logistics network to expedite the delivery of genuine spare parts, minimizing your potential downtime.