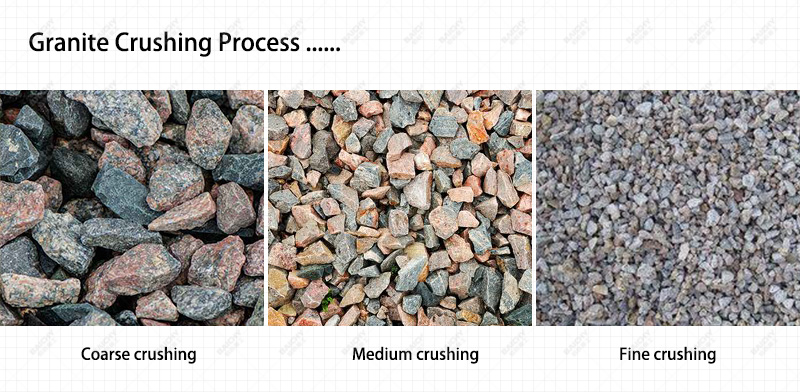

Granite, a hard rock with a Mohs hardness of 6-7, has long faced three major industry challenges in its crushing: high wear, high energy consumption, and low yield. Conventional crushing equipment often suffers from rapid hammer wear, overheating and shutdown, and excessive flake content when processing granite.

Baichy Heavy Industry, with 20 years of experience in mining machinery manufacturing, has developed a comprehensive crushing solution specifically tailored to the characteristics of granite.

Our granite-specific crusher production line features:

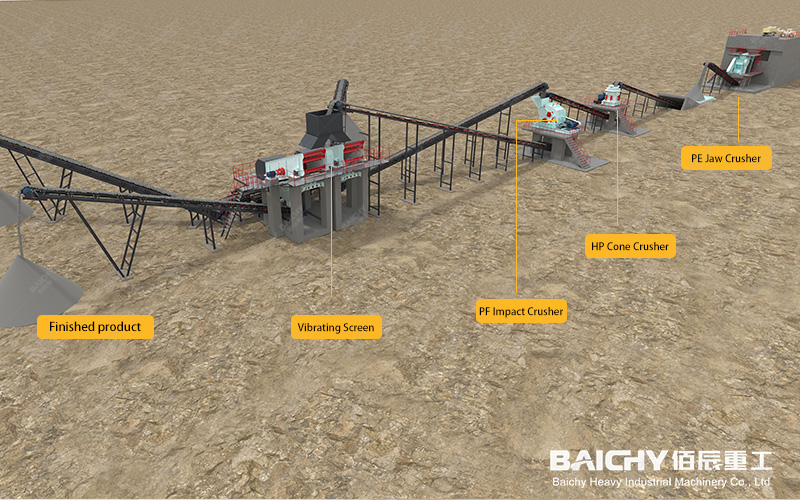

1. Primary Crushing - Jaw Crusher Series

• PE Series Hydraulically Protected Jaw Crusher: Utilizes a dual system of "hydraulic overload protection + wedge adjustment" to process granite slabs with a particle size ≤1500mm

• Unique "curved tooth plate" design with precisely calculated engagement angle improves wear resistance by 40% compared to traditional models

On-site Case Study: A granite quarry in Yunnan uses a PE-600×900 model, achieving 8,000 hours of continuous operation without jaw plate replacement

2. Secondary Crushing - Cone Crusher Series

HP Series Hydraulic Cone Crusher: Utilizes a laminated crushing principle and features an intelligent control system for real-time spindle speed adjustment

• Key components are cast from high-chromium alloy composites, resulting in a service life three times that of ordinary manganese steel

• Technical Parameters: Feed size ≤350mm, adjustable output from 80 to 1,500 t/h

3. Shaping Crushing - Impact Crusher Series

• PF Series High-Power Impact Crusher: Unique "Impact + Grinding" Dual-Action Chamber Design

• Finished product contains ≥90% cubes, with flake content controlled within 5%

Why choose our granite crushing solution?

1. Core Technology Advantages

• Composite Wear-Resistant Material: Our independently developed GT-30 alloy, tested by the Central South University Materials Laboratory, boasts a compressive strength of 850 MPa.

• Energy-Saving System: Equipped with a variable frequency drive, it consumes 15-20% less energy than traditional equipment.

• Intelligent Monitoring: Vibration sensors and temperature monitoring modules enable predictive fault diagnosis.

2. Production Line Design Services

We offer three stages of customized services:

• Ore Testing: Free hardness testing of granite samples (test report template provided).

• Solution Design: Optimal equipment configuration based on production capacity requirements (with flow chart).

• Installation Training: On-site guidance from dispatched engineers (including VR virtual installation demonstrations).

3. Success Case Studies

Granite Project in Quang Tri Province, Vietnam:

• Raw Material Characteristics: Off-white granite with a 25% quartz content.

• Configuration: PE-750×1060 jaw crusher + PYB-1200 Cone Crusher + PF-1320 Impact Crusher

• Operational Performance: 280 t/h 85% of finished aggregate is 5-31.5mm, and the equipment has a continuous operation rate of 94%.

Fujian Nan'an Sand and Gravel Aggregate Project:

• Special Requirements: Simultaneous production of 0-5mm crushed sand and 10-20mm roadbed material is required.

• Innovative Solution: Adopting a dual closed-circuit system of cone crusher + vertical shaft impact crusher.

• Economic Benefits: Reduced the overall cost per ton of crushed stone by 3.8 yuan, shortening the payback period to 14 months.

FAQ

Q: Should I choose a fixed or mobile crushing plant for granite processing?

A: We recommend choosing based on the project lifecycle:

• Fixed: Suitable for long-term mining (over 3 years), with advantages of high production capacity and stability.

• Mobile: Suitable for temporary projects. We recommend our MP-YG series crawler mobile crusher, available with diesel/electric power options.

Q: What is the replacement cycle for wear parts in a granite crusher?

A: Under normal operating conditions:

• Jaw plates: Wear is approximately 1.2-1.8mm per 10,000 tons of granite processed.

• Cone crushing wall: Typical service life is 6-8 months.

• Impact plate: Hydraulically reversible, with a combined service life of 9-12 months.

Q: How do you control dust during the granite crushing process?

We offer a three-stage dust removal solution:

• Source dust suppression: Atomizing spray system at the feed port.

• Dust collection: Pulse-type bag filter (dust removal efficiency ≥ 99%).

• End-of-line treatment: Equipped with an online PM2.5 monitoring device.

Service Commitment and Technical Guarantee

• Warranty Policy: 3-year warranty on core components (including spindles, frames, etc.).

• Accessories: We maintain a 20 million RMB inventory of wear-resistant parts and respond to urgent orders within 8 hours.

• Upgrade Service: We offer intelligent equipment upgrades (including the option of installing a 5G remote operation and maintenance module).

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)