1. Industry Pain Points: Why do stone production lines need to be upgraded?

In the sand and gravel aggregate industry, traditional 300 t/h stone production lines often face the following challenges:

• High energy consumption: Old-fashioned crushers and vibrating screens are inefficient, and electricity costs account for a significant portion of the production cost.

• Production bottlenecks: Equipment wear reduces production, making it difficult to meet market demand.

• Environmental pressures: Dust and noise levels exceed standards, posing regulatory risks.

• High reliance on manual labor: Traditional production lines rely on manual operation, resulting in high failure rates and high maintenance costs.

Solution: Through intelligent and energy-saving transformation, production efficiency can be increased by over 30% and operating costs reduced by 20%!

2. Upgrade Plan: Four Core Optimization Strategies

2.1 Crushing Equipment Upgrade - Improving Crushing Efficiency

Solution ①: Cone Crusher Replacing Jaw Crusher (Suitable for Hard Rock)

• Recommended Equipment: HP300 Multi-Cylinder Hydraulic Cone Crusher (300-350 tons per hour, 15% lower energy consumption)

• Advantages: Laminated crushing, fine-grained finished product, and reduced return rate.

Solution ②: Impact Crusher Optimization (Suitable for Medium-Hard Rock)

• Adopting the VSI6X vertical shaft impact crusher, achieving both "rock-on-rock" and "rock-on-iron" dual-mode crushing improves fine crushing efficiency.

2.2 Screening System Modification - Reducing Blockage & Improving Screening Accuracy

• High-frequency vibrating screens replace traditional screens, increasing screening efficiency by 25%.

• Multi-layer screen design (such as the 3YK3070 vibrating screen) enables precise grading (0-5mm, 5-10mm, 10-20mm). • Intelligent amplitude adjustment automatically optimizes screening efficiency based on material characteristics.

2.3 Automated Control System - Reduced Labor Costs

• PLC intelligent central control system monitors equipment operating status (current, temperature, vibration) in real time.

• AI predictive maintenance provides early warning of failures of vulnerable parts such as bearings and belts, reducing downtime.

• Remote monitoring (mobile/computer management) enables "unattended" production.

2.4 Environmental Protection and Energy Saving Optimization - Compliant with Green Mining Standards

• Dry dust removal system (pulse bag filter), dust emissions ≤ 20mg/m³.

• Enclosed conveyor belt + spray dust suppression reduces dust generation.

• Variable frequency energy-saving motor, achieving an overall energy saving of 10%-15%. 3. Case Study: The Upgraded Results of a Granite Production Line

Before the Upgrade:

• Production Capacity: 280 tons/hour (with large fluctuations)

• Power Consumption: 28 kWh/ton

• Labor: 3 people/shift

After the Upgrade:

• Production Capacity Stable at 350 tons/hour (25% Increase)

• Power Consumption Reduced to 22 kWh/ton (21% Energy Saving)

• Single-person Inspection (Automated Control)

• Environmental Compliance and Successful Environmental Assessment

4. Future Trends: Intelligent Development of Stone Production Lines

• Digital Twin Technology: 3D Simulation of Production Line Operations to Optimize Process Parameters

• 5G + IoT: Device Interconnection and Big Data Analysis to Increase Production Capacity

• New Energy Power Supply: Photovoltaic + Energy Storage to Further Reduce Electricity Costs

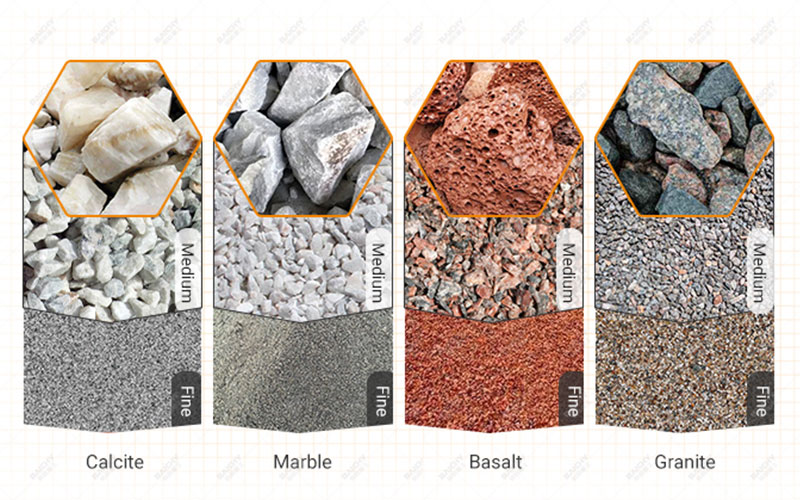

5. Conclusion: How to Choose the Right Upgrade Solution? Hard rock (granite, basalt) → Prioritize a cone crusher + impact crusher combination.

Medium-hard rock (limestone, dolomite) → Optimize impact crusher + high-efficiency screening.

Limited budget? You can upgrade key equipment (such as the crusher or screening system) first, then proceed in phases.

Does your production line need an upgrade? Leave us a message to discuss your needs and get a customized solution!

Keyword optimization: 300 t/h stone production line upgrade | Crusher upgrade | Sand and gravel aggregate energy-saving solution | Intelligent stone production | HP300 cone crusher | Environmentally friendly sand and gravel production line

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)