Gold ore refers to gold-bearing ore extracted from mines manually or mechanically, which also contains other metal impurities. Gold is crystalline at room temperature, with the equiaxed crystal system and cubic centered lattice. The natural good crystal form is extremely rare, often in irregular granular, agglomerated, flake, reticulated, dendritic, fibrous, and spongy aggregates. Gold ore is very abundant on earth.

As a professional mining manufacturer, Baichy Machinery has gold ore crushers and relative equipment for sale. We can provide gold ore crushing equipment and grinding mill machine, including feeder and vibrating screening products of low price and high quality. Not only fixed crushers, but Baichy Machinery can provide you with small-scale portable crushers, mobile crusher plants, and many kinds of high-efficiency equipment.

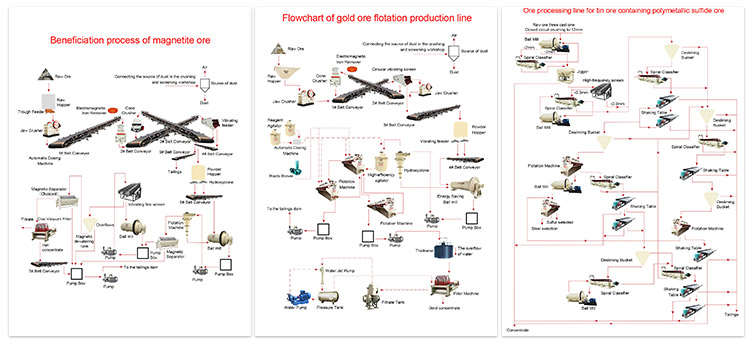

Here we introduce the complete gold ore crushing and processing process.

1. Firstly, according to gold ore hardness, sulfur content, carbon content, other minerals content, etc, which affect the machines, methods, and costs, we will choose the suitable machine to operate.

2. Secondly, we should send the gold ore into a series of crushers (jaw crusher, cone crusher or impact crusher, etc.) and grinding mills (ball mill, vertical mill, etc.) to reduce the size of the ore particles and expose the mineral.

3. During the grinding process, the gold ore slurry will be classified to re-grind again and the qualified slurry is sent to the next process. The purpose of classifying is to recover coarse gold and create favorable conditions for flotation and cyanidation processes, which can improve the beneficiation indicators, and improve the recovery rate of gold. It plays a positive role in increasing production and reducing costs.

4. Next is the flotation process. This process removes up to 93% of the gold and 70% of the silver from the ore. And then the gold is pulled from the solution and attached to the carbon. Then the gold is stripped from the carbon by washing it with a caustic cyanide solution.

5. Finally, the extracted gold is further smelted in the furnace and processed into pure gold.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)

Further reading:

How To Reduce The Energy Consumption Of Ball Mill? 5 Practical Energy-Saving Tips

Iron Ore Beneficiation Process: Magnetic Separation/Flotation/Gravity Separation