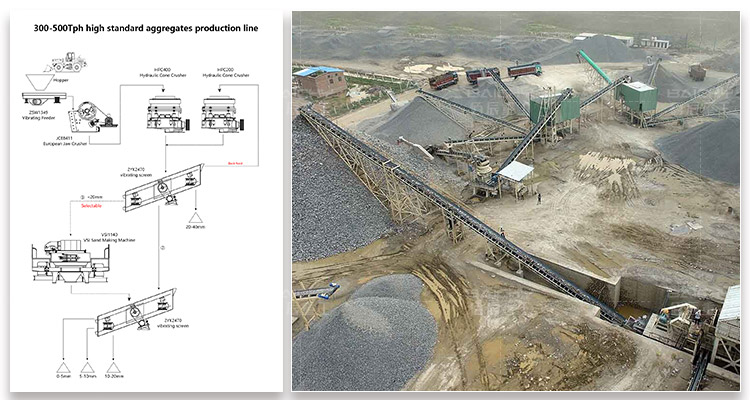

Recommended equipment - made with your mind, good products can speak Project Introduction:

The company has been investigating crushing equipment in China for nearly half a year, but was still attracted by Baichy's strong processing capacity and sophisticated technology, and purchased a 300-500T/H sand and gravel aggregate production line. Granular shapes meet customer requirements. This production line has now become a new model project of Baichy in Kazakhstan.

Device Configuration:

Vibrating feeder, jaw crusher, cone crusher, sand-making machine, conveyor belt, vibrating screen, etc.

Production Line Solutions:

The plan uses the European version of the jaw crusher with a processing capacity of 200-500t/h as the primary crushing equipment to perform the primary crushing of large materials and then uses the HPC400 cone crusher with a processing capacity of 200-500t/h for secondary crushing. The belt conveyor crushes the crushed materials. It is transported to the vibrating screen for screening. Everyone has noticed that in the design of the secondary crushing, Baichy Heavy Industry has put 2 cone crushers of different models. In fact, this is a relatively classic configuration on the domestic production line. The crushing pressure in the secondary crushing allows the stones on the top layer of the sieve to return to the HPC200 cone crusher with a processing capacity of 100-200t/h for secondary crushing and then re-enter the sieve for screening.

Note that the particle size required by the customer is 0-5mm, 5-10mm, 10-20mm, and 20-40mm, so we first screen the large material, the finished product of the 2YK2470 type vibrating screen 20-40mm is the particle size required by the customer, less than 20mm The stone is then conveyed by the belt conveyor to the sand making machine of VSI1140 with a processing capacity of 225-260t/h for sand making, and finally conveyed by the belt conveyor to the vibrating screen of 2YK2470 for screening to 0-5mm, 5-10mm, 10-20mm Finished sand.

This scheme has been designed and put into production. At present, the on-site operation is stable and the output is stable.

Client feedback

The production and processing system of the sand and gravel aggregate production line introduced by our company is reasonable in scale, layout, and technological process design, with a smooth conveying line and flexible adjustment. The produced sand and gravel aggregate can meet the engineering needs in terms of quantity, quality and strength, and has now become the main production line of our company's sand and gravel aggregate.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)