1. Overview of silica sand production line

Silica sand (quartz sand) is an important raw material for glass, casting, photovoltaic, electronics and other industries. Its purity and particle size directly affect product quality. The silica sand production line processes raw ore into high-quality silica sand that meets the standards of different industries through crushing, sorting, purification, drying and other processes.

1.1 Core advantages:

✔ Efficient sorting:using magnetic separation, flotation, gravity separation and other technologies to improve SiO₂ purity (up to 99.9%).

✔ Energy saving and environmental protection:low energy consumption design, equipped with dust recovery system, in line with environmental protection standards.

✔ Customized solution:matching the best process according to ore characteristics (hardness, impurity content).

2. Silica sand production line process flow

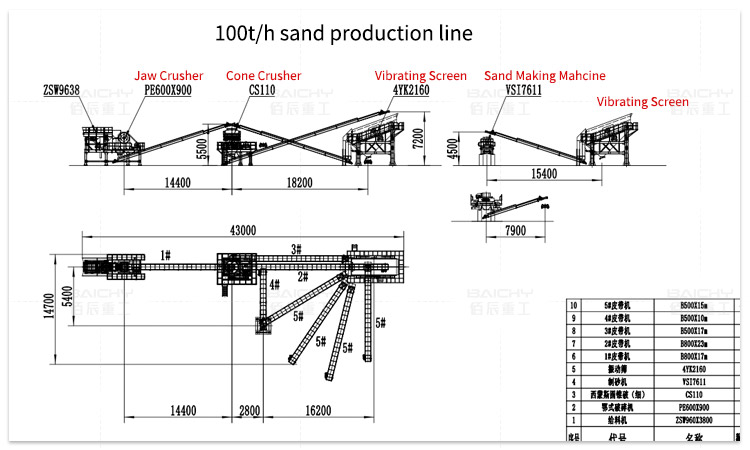

2.1 Crushing stage

• Coarse crushing: jaw crusher handles large pieces of raw ore (≤50mm).

• Fine crushing: Cone crusher/impact crusherfurther refines (≤10mm).

2.2 Sorting and purification

• Magnetic separation: remove iron impurities (applicable to photovoltaic grade high-purity silica sand).

• Flotation: separate associated minerals such as feldspar and mica.

• Gravity separation: spiral classifier/shaking table classification to ensure uniform particle size.

2.3 Dehydration and drying

• Dehydration screen + dryer, control moisture ≤0.5%, meet packaging requirements.

3. Industry application cases

| Industry | Silica sand requirements | Solution highlights |

| Glass manufacturing | SiO₂≥98.5%, particle size 0.1-0.5mm | High-efficiency sorting + automated packaging, production capacity 200T/H |

| Photovoltaic silicon wafers | SiO₂≥99.9%, low iron and low aluminum | Magnetic separation + acid washing purification, purity compliance rate 99% |

| Foundry sand | AFS particle size 40-70, high temperature resistance | Customized drying system to reduce clay content |

4. Why choose our silica sand production line?

✔ Mature technology: 20 years of industry experience, 10,000+ successful cases (including overseas projects).

✔ Intelligent control: PLC automation system, real-time monitoring of energy consumption and output.

✔ After-sales guarantee: 24-hour technical support, lifelong maintenance of equipment.

5. Frequently Asked Questions (FAQ)

Q1: What is the investment cost of a silica sand production line?

According to the production capacity (50-500T/H) and process complexity, the investment range is about 500,000-5 million, and installment payment plans are provided.

Q2: How long is the construction period of the production line?

Standard configuration 3-6 months, including installation and commissioning and employee training.

Q3: Can it process silica sand ore with high clay content?

A scrubber + cyclone can be added to effectively remove clay impurities.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.